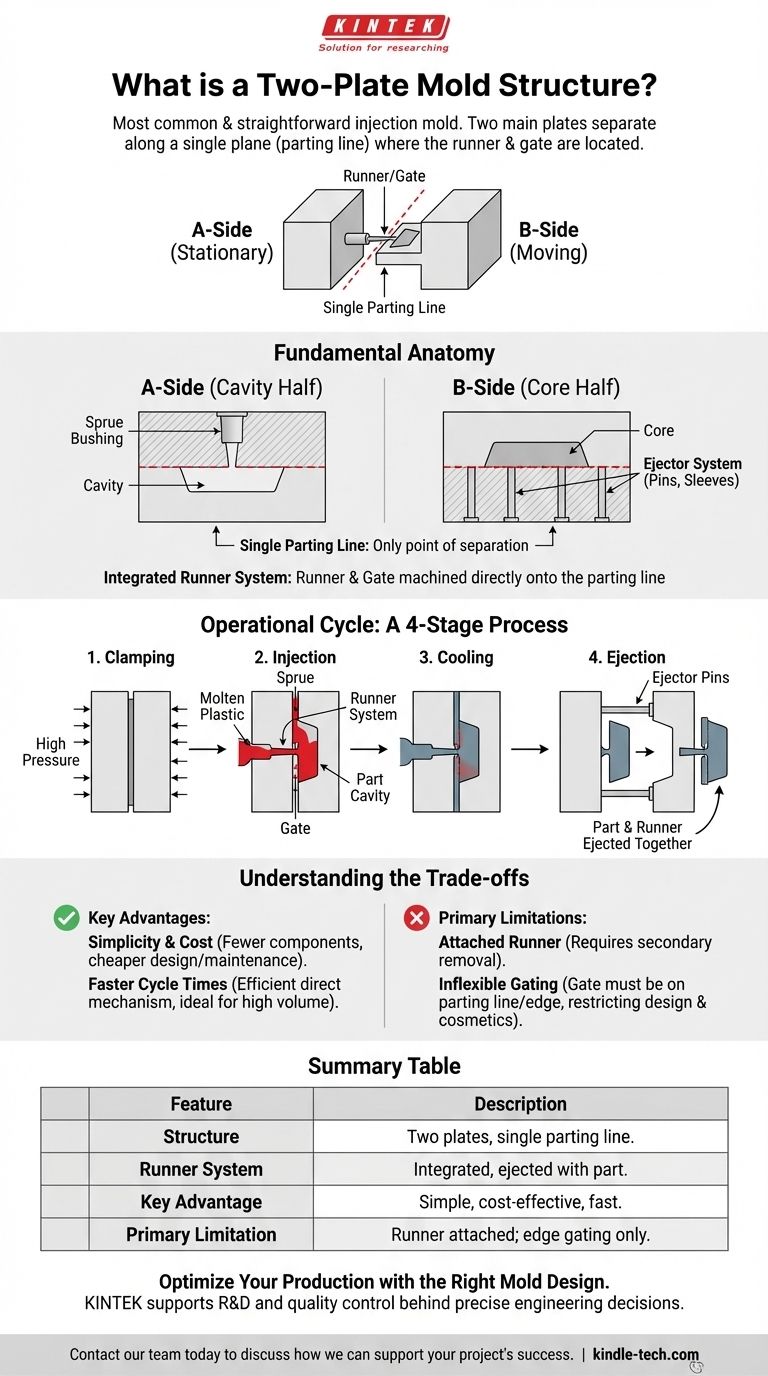

At its core, a two-plate mold is the most common and straightforward type of injection mold used in manufacturing. It is defined by its simple construction, consisting of two main plates that separate along a single plane, known as the parting line. In this design, the channels that deliver molten plastic (the runner and gate) are located on this same parting line, directly alongside the part's cavity.

The defining characteristic of a two-plate mold is its simplicity: a single parting line for both the part and the runner system. This makes it cost-effective and reliable, but it also means the runner remains attached to the part after molding, requiring a secondary removal step.

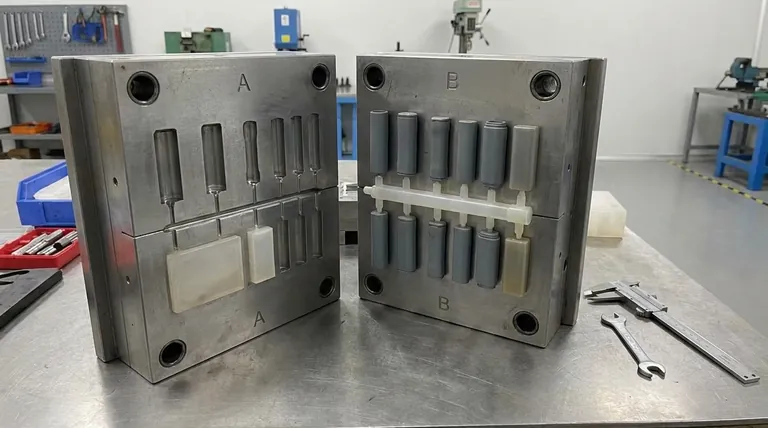

The Fundamental Anatomy of a Two-Plate Mold

To understand its function, it's helpful to visualize its core components. The structure is typically divided into two halves: the "A" side and the "B" side.

The A-Side (Cavity Half)

This is the stationary half of the mold that mounts to the injection molding machine. It contains the sprue bushing, where the molten plastic first enters the mold from the machine's nozzle.

The B-Side (Core Half)

This is the moving half of the mold. It contains the core of the part geometry and, crucially, the entire ejection system (pins, sleeves, etc.) that pushes the finished part out.

The Single Parting Line

When the mold closes, these two halves meet to form the complete part cavity. The single plane where they meet is the parting line. This is the only place the mold separates during its operational cycle.

The Integrated Runner System

As noted in the definition, the runner channels and the gate (the specific point of entry into the cavity) are machined directly into the surfaces of the plates along this parting line. This is a critical design feature with significant implications.

The Operational Cycle: A Step-by-Step View

The elegance of the two-plate mold is in its direct, four-stage process.

Stage 1: Clamping

The two mold plates (A-side and B-side) are pressed together under high pressure, creating a sealed cavity for the part.

Stage 2: Injection

Molten plastic is injected through the sprue, travels through the runner system, and enters the part cavity through the gate.

Stage 3: Cooling

The plastic is held under pressure inside the mold until it cools and solidifies into the shape of the part and the runner.

Stage 4: Ejection

The mold opens along its single parting line. Ejector pins on the B-side then push the solidified part out. Because the runner system is on the same plane, the part and the runner are ejected together as a single piece.

Understanding the Trade-offs

The simple design of a two-plate mold presents clear advantages and equally clear limitations that every product designer and engineer must understand.

Key Advantage: Simplicity and Cost

This is the primary reason two-plate molds are so prevalent. With fewer components and no complex moving parts, they are faster and cheaper to design, manufacture, and maintain.

Key Advantage: Faster Cycle Times

The direct open-and-eject mechanism is incredibly efficient. This simplicity often translates to shorter cycle times, which is critical for high-volume production where every second counts.

Primary Limitation: The Attached Runner

The runner system does not detach automatically. It remains connected to the part after ejection and must be removed in a secondary operation, either by a human operator or an automated process.

Primary Limitation: Inflexible Gating

Since the gate must be located on the parting line, design options are restricted. You can only place a gate on the part's outer perimeter. Gating into the center of a part for optimal flow or cosmetic appearance is not possible with a standard two-plate design. This also means the part will always have a gate mark, or vestige, on its edge.

Making the Right Choice for Your Goal

Selecting a mold structure is a foundational decision in manufacturing. Use these principles to guide your choice.

- If your primary focus is cost-efficiency and high-volume production: The two-plate mold is almost always the superior choice due to its simple design, lower cost, and faster cycle times.

- If your part design can accommodate a gate mark on its edge: A two-plate mold is a perfect fit, as its gating is restricted to the parting line.

- If your part requires a pristine cosmetic surface or central gating for structural integrity: You must explore a more complex structure, like a three-plate mold, to achieve your design intent.

By understanding the elegant simplicity of the two-plate mold, you can make deliberate, cost-effective decisions for the vast majority of injection molding projects.

Summary Table:

| Feature | Description |

|---|---|

| Structure | Two main plates (A-side & B-side) that separate along a single parting line. |

| Runner System | Integrated into the parting line; ejected with the part. |

| Key Advantage | Simplicity, lower cost, faster cycle times. |

| Primary Limitation | Runner remains attached, requiring secondary removal; gating restricted to part edge. |

Optimize Your Production with the Right Mold Design

Understanding the right mold structure is critical for the efficiency and quality of your manufacturing process. At KINTEK, we specialize in providing the robust lab equipment and consumables that support the R&D and quality control behind these precise engineering decisions.

Let our expertise in laboratory solutions help you achieve manufacturing excellence. Contact our team today to discuss how we can support your project's success.

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What functions do graphite molds perform during SPS? Powering High-Performance Solid-State Battery Densification

- How long do you leave a ceramic slip in a mold? Master Timing for Perfect Casts

- What is a press die set? A Precision System for Efficient Mass Production

- What are the primary functions of high-purity graphite molds in YAG ceramic sintering? Enhance Material Purity & Density

- How does a 3 plate Mould work? A Guide to Advanced Injection Molding for Complex Parts

- What are the considerations for Mould design? Optimize for Quality, Speed, and Cost

- What is the function of high-purity graphite molds in vacuum hot press sintering? Achieve Dense ZrC-SiC Composites

- What role do specialized pressure dies play in Cold Sintering multi-layer batteries? Ensure Flawless Device Integration