The primary advantage of sputtering over older thermal evaporation methods is its superior control over the composition of the deposited film. Because sputtering is a physical process that mechanically ejects atoms from a source material, it can faithfully replicate the composition of complex alloys and compounds onto a substrate. Older methods that rely on heating and evaporation can alter the material's chemistry during the process.

The core difference comes down to physics versus chemistry. Sputtering uses momentum transfer to deposit materials, preserving their original recipe. Thermal evaporation uses heat, which can selectively boil off certain elements faster than others, changing the recipe of the final coating.

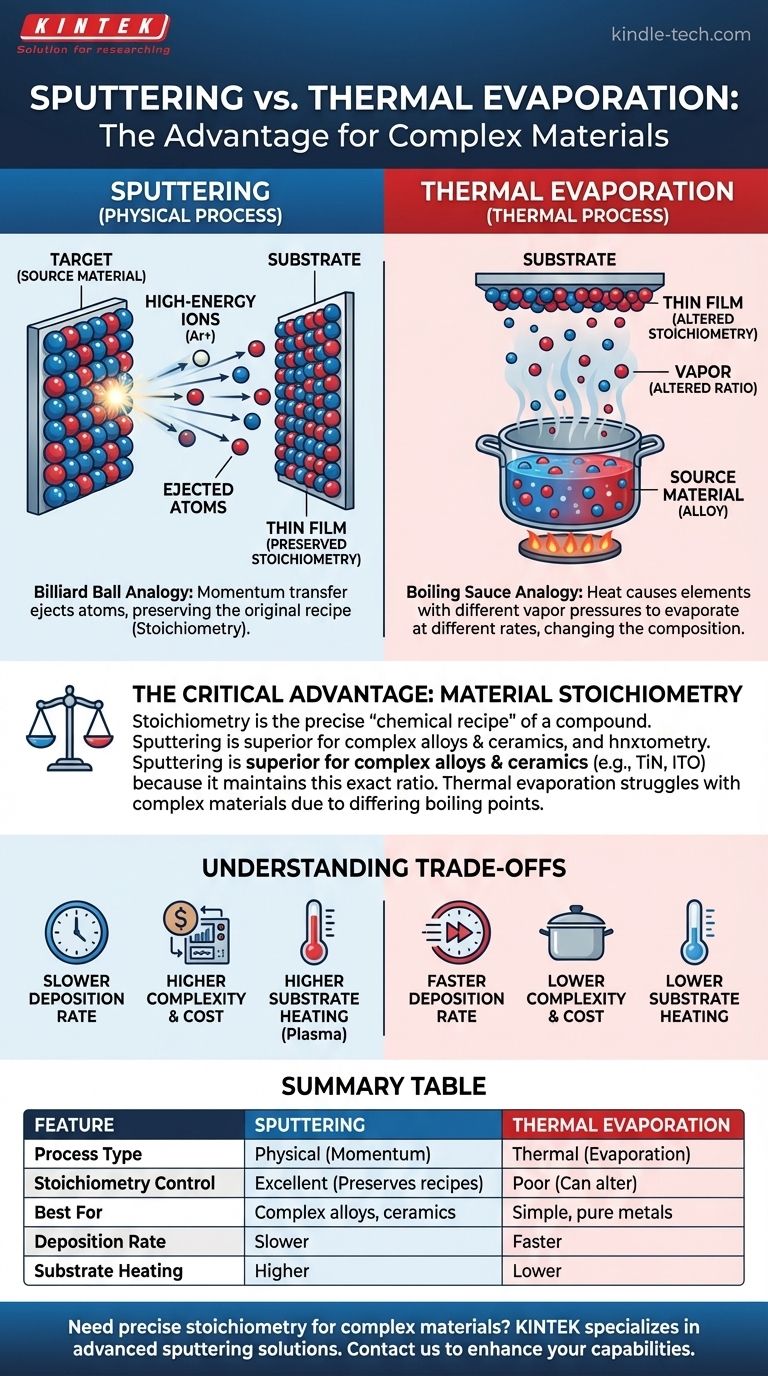

The Fundamental Difference: Physical vs. Thermal Process

To understand the advantage of sputtering, we must first understand the fundamental difference in how it operates compared to a classic vacuum deposition technique like thermal evaporation.

How Sputtering Works: A Billiard Ball Analogy

Sputtering is a physical vapor deposition (PVD) process. Imagine the source material (called the "target") as a tightly packed rack of billiard balls.

High-energy ions, typically of an inert gas like argon, are fired at this target. These ions act like a powerful cue ball, striking the target and transferring momentum.

This collision physically knocks atoms or molecules of the target material loose, ejecting them into the vacuum chamber. These ejected atoms then travel and deposit onto the substrate, forming a thin film.

How Thermal Evaporation Works: Boiling a Sauce

Thermal evaporation is a much older technique. It works by heating the source material in a vacuum until it begins to boil and evaporate (or sublimate).

Think of it like boiling a complex sauce on a stove. The vapor from the "sauce" rises and condenses on a cool surface held above it—this surface is the substrate.

The process relies on changing the material from a solid or liquid into a gas phase through heat, which then re-condenses as a solid film.

The Critical Advantage: Preserving Material Stoichiometry

The physical mechanism of sputtering is what gives it a decisive edge when working with complex materials. This advantage is known as preserving stoichiometry.

What is Stoichiometry?

In simple terms, stoichiometry is the "chemical recipe" of a compound or alloy. It's the precise ratio of different elements within the material.

For advanced materials like semiconductors, optical coatings, or hard coatings, maintaining this exact recipe is critical for the material to have the desired properties.

Why Sputtering Excels

Because sputtering physically knocks atoms off the target via momentum, it ejects the different elements in roughly the same ratio as they exist in the source material.

If your target is a complex ceramic like indium tin oxide (ITO) or a hard alloy like titanium nitride (TiN), sputtering ensures the film deposited on your substrate has that same chemical makeup.

The Limitation of Evaporation

Thermal evaporation struggles with complex materials because different elements have different vapor pressures (i.e., they boil at different temperatures or rates).

When you heat an alloy, the element with the higher vapor pressure (lower boiling point) will evaporate more readily. This means the vapor, and therefore the deposited film, will be richer in that one element, altering the material's stoichiometry and its properties.

Understanding the Trade-offs

Sputtering is not universally superior. Its advantages come with specific trade-offs that make other methods more suitable for certain applications.

Deposition Rate

Sputtering is often a slower process than thermal evaporation. For applications where a thick coating of a simple, pure metal is needed quickly, evaporation can be far more efficient.

System Complexity and Cost

Sputtering systems are more complex. They require high-voltage power supplies, magnetic fields (in magnetron sputtering), and precise gas flow control systems. This generally makes them more expensive to purchase and operate than simple thermal evaporators.

Substrate Heating

The energetic bombardment of ions and plasma during sputtering can transfer a significant amount of heat to the substrate. This can be problematic for temperature-sensitive substrates like plastics or certain electronic components.

Making the Right Choice for Your Goal

Your choice of deposition method should be dictated by your material and the desired outcome of the final film.

- If your primary focus is depositing a complex alloy or ceramic (e.g., TiN, ITO): Sputtering is the superior choice for maintaining the material's precise chemical composition.

- If your primary focus is rapidly coating a simple, pure metal (e.g., Aluminum, Gold): Thermal evaporation is often faster, simpler, and more cost-effective.

- If your primary focus is coating a heat-sensitive substrate: You must carefully consider the potential for plasma heating in sputtering and might explore low-temperature variations or alternative methods.

Ultimately, understanding the physical mechanism behind each technique is the key to selecting the right tool for your specific engineering challenge.

Summary Table:

| Feature | Sputtering | Thermal Evaporation |

|---|---|---|

| Process Type | Physical (Momentum Transfer) | Thermal (Evaporation) |

| Stoichiometry Control | Excellent (Preserves complex recipes) | Poor (Can alter composition) |

| Best For | Complex alloys, ceramics (e.g., TiN, ITO) | Simple, pure metals (e.g., Au, Al) |

| Deposition Rate | Slower | Faster |

| Substrate Heating | Higher (Plasma bombardment) | Lower |

Need to deposit complex materials with precise stoichiometry? KINTEK specializes in advanced sputtering systems and lab equipment designed for reliable, high-quality thin film deposition. Our experts can help you select the ideal equipment to meet your specific research or production goals. Contact our team today to discuss your application and discover how our solutions can enhance your laboratory's capabilities!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use