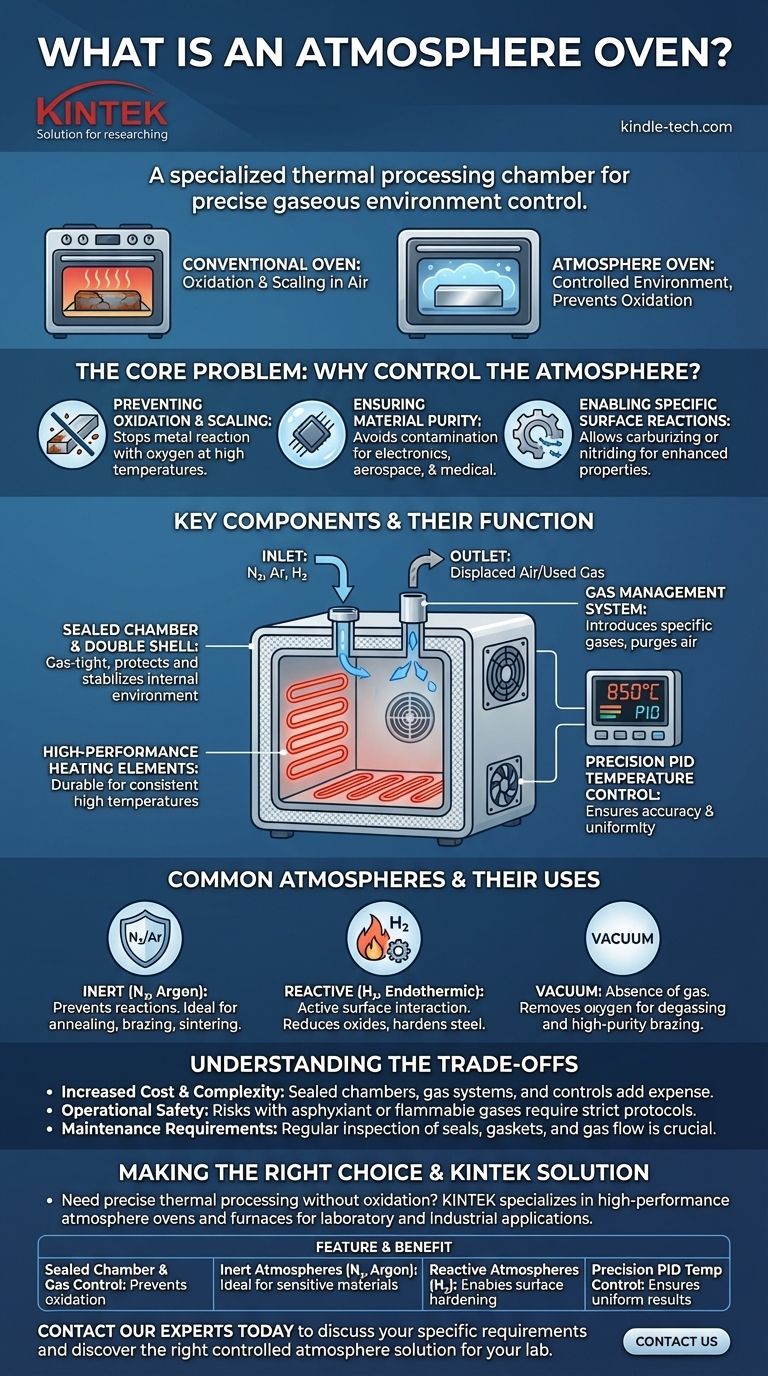

An atmosphere oven, often called an atmosphere furnace, is a specialized thermal processing chamber that allows for precise control over the gaseous environment surrounding the material being heated. Unlike a conventional oven that operates in ambient air, this type of oven enables operators to introduce specific inert or reactive gases. This control is critical for preventing unwanted chemical reactions, such as oxidation, and for ensuring the integrity of materials at high temperatures.

The primary function of an atmosphere oven is not just to heat a material, but to do so within a specific, controlled gas environment. This prevents oxidation and other reactions, ensuring the material's integrity during high-temperature processing.

The Core Problem: Why Control the Atmosphere?

Heating materials in the presence of air can fundamentally alter their properties, often in undesirable ways. An atmosphere oven solves this problem by replacing the oxygen-rich air with a controlled gas that serves a specific purpose.

Preventing Oxidation and Scaling

At high temperatures, most metals will readily react with oxygen in the air. This process, known as oxidation, can create a layer of scale on the material's surface, compromising its finish, dimensions, and structural integrity. An inert atmosphere prevents this.

Ensuring Material Purity

For sensitive materials used in electronics, aerospace, or medical applications, even minor surface contamination can lead to component failure. By processing parts in a pure, inert gas, you can avoid introducing contaminants that are present in ambient air.

Enabling Specific Surface Reactions

In some cases, the goal is not to prevent a reaction but to cause a very specific one. Processes like carburizing (adding carbon to steel) or nitriding (adding nitrogen) require a reactive atmosphere to change the surface chemistry of a part, often to increase its hardness and wear resistance.

Key Components and Their Function

The ability to maintain a pristine, controlled environment at high temperatures requires specialized construction and components.

The Sealed Chamber

The foundation of any atmosphere oven is a gas-tight, sealed processing chamber. These are often ruggedly constructed with a double shell, where the space between the inner and outer walls can be cooled, typically by a fan. This protects the outer shell from extreme heat and helps maintain a stable internal environment.

Gas Management System

To control the atmosphere, the oven must have inlet and outlet ports. The inlet allows for the introduction of specific gases (like nitrogen, argon, or hydrogen), while the outlet allows the displaced air or used gas to be safely vented. This system enables the purging of air before a heating cycle begins.

Precision Temperature Control

Maintaining a stable temperature is just as critical as controlling the gas. These ovens use a digital PID (Proportional-Integral-Derivative) controller, which offers far greater accuracy than a simple thermostat. It continuously adjusts the power to the heating elements to prevent temperature overshooting and maintain uniformity throughout the chamber.

High-Performance Heating Elements

To achieve and sustain high temperatures consistently, atmosphere ovens rely on durable, long-service-life heating elements. These are designed for reliable performance over thousands of hours, ensuring that processes are repeatable and predictable.

Common Atmospheres and Their Uses

The gas chosen depends entirely on the desired outcome for the material being processed.

Inert Atmospheres

Gases like nitrogen and argon are used when the goal is simply to prevent any chemical reaction. They are ideal for processes like annealing, brazing, and sintering of sensitive metals.

Reactive Atmospheres

Gases such as hydrogen or endothermic gas are used to actively interact with the material's surface. Hydrogen is a reducing agent that can remove oxides, while other gas mixtures are used for hardening steel.

Vacuum

A vacuum is the ultimate controlled atmosphere—the absence of one. Pulling a vacuum removes oxygen and other gases, which is critical for processes like degassing materials or performing high-purity brazing.

Understanding the Trade-offs

While incredibly powerful, atmosphere ovens introduce complexities not found in standard industrial ovens.

Increased Cost and Complexity

The need for a perfectly sealed chamber, gas delivery plumbing, safety interlocks, and precision controls makes these systems significantly more expensive and complex to operate than their conventional counterparts.

Operational Safety

Working with industrial gases carries inherent risks. Inert gases like nitrogen and argon are asphyxiants, while reactive gases like hydrogen are highly flammable. Proper ventilation, safety protocols, and operator training are non-negotiable.

Maintenance Requirements

The seals, gaskets, and gas flow systems require regular inspection and maintenance. A small leak can compromise the atmosphere, ruin a batch of parts, and create a potential safety hazard.

Making the Right Choice for Your Process

Selecting the correct thermal processing equipment depends entirely on your material and end goal.

- If your primary focus is simple drying or curing without surface chemistry concerns: A standard industrial oven is often sufficient and more cost-effective.

- If your primary focus is preventing oxidation on sensitive metals during heat treatment: An inert atmosphere oven using nitrogen or argon is the correct choice.

- If your primary focus is actively changing a material's surface properties: A reactive atmosphere oven designed for specific process gases is necessary.

Ultimately, an atmosphere oven provides absolute control, transforming high-temperature heating from a simple process into a precise manufacturing or scientific tool.

Summary Table:

| Feature | Benefit |

|---|---|

| Sealed Chamber & Gas Control | Prevents oxidation, scaling, and contamination during heating. |

| Inert Atmospheres (N₂, Argon) | Ideal for annealing, brazing, and sintering sensitive materials. |

| Reactive Atmospheres (H₂) | Enables surface hardening processes like carburizing and nitriding. |

| Precision PID Temperature Control | Ensures uniform, repeatable results for critical applications. |

Need precise thermal processing without oxidation?

KINTEK specializes in high-performance atmosphere ovens and furnaces for laboratory and industrial applications. Our equipment ensures material integrity for sensitive processes in metals, electronics, and aerospace.

Contact our experts today to discuss your specific requirements and discover the right controlled atmosphere solution for your lab.

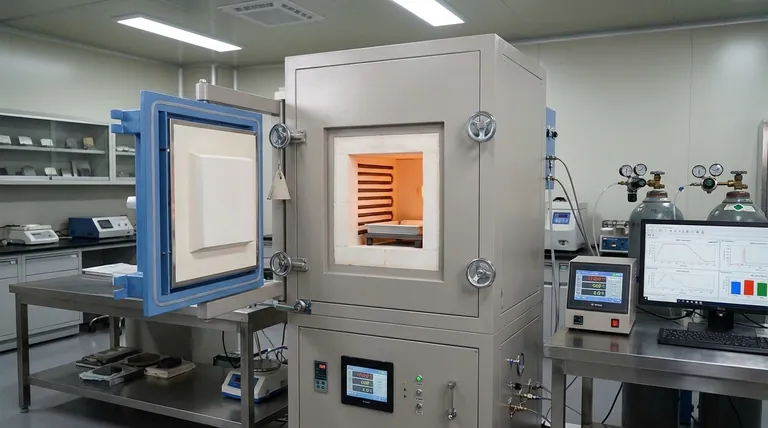

Visual Guide

Related Products

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- How we can develop inert atmosphere for a chemical reaction? Master Precise Atmospheric Control for Your Lab

- What is meant by inert atmosphere? A Guide to Preventing Oxidation & Ensuring Safety

- What gases are used in inert atmospheres? Choose the Right Gas for Non-Reactive Environments

- What is the purpose of using an atmosphere-controlled heating furnace for Cu reduction? Achieve Active Catalytic States