A primary example of Physical Vapor Deposition (PVD) is sputtering, a process where a target material is bombarded with high-energy ions, causing atoms to be ejected and deposited onto a substrate. Sputtering, along with thermal evaporation, are the two most common PVD methods used to create ultra-thin, high-performance films on a wide range of surfaces.

PVD is not a single process, but a family of vacuum deposition techniques. Its core purpose is to apply an exceptionally thin coating to a material, fundamentally enhancing its surface properties—like hardness, wear resistance, or thermal stability—without altering the underlying object.

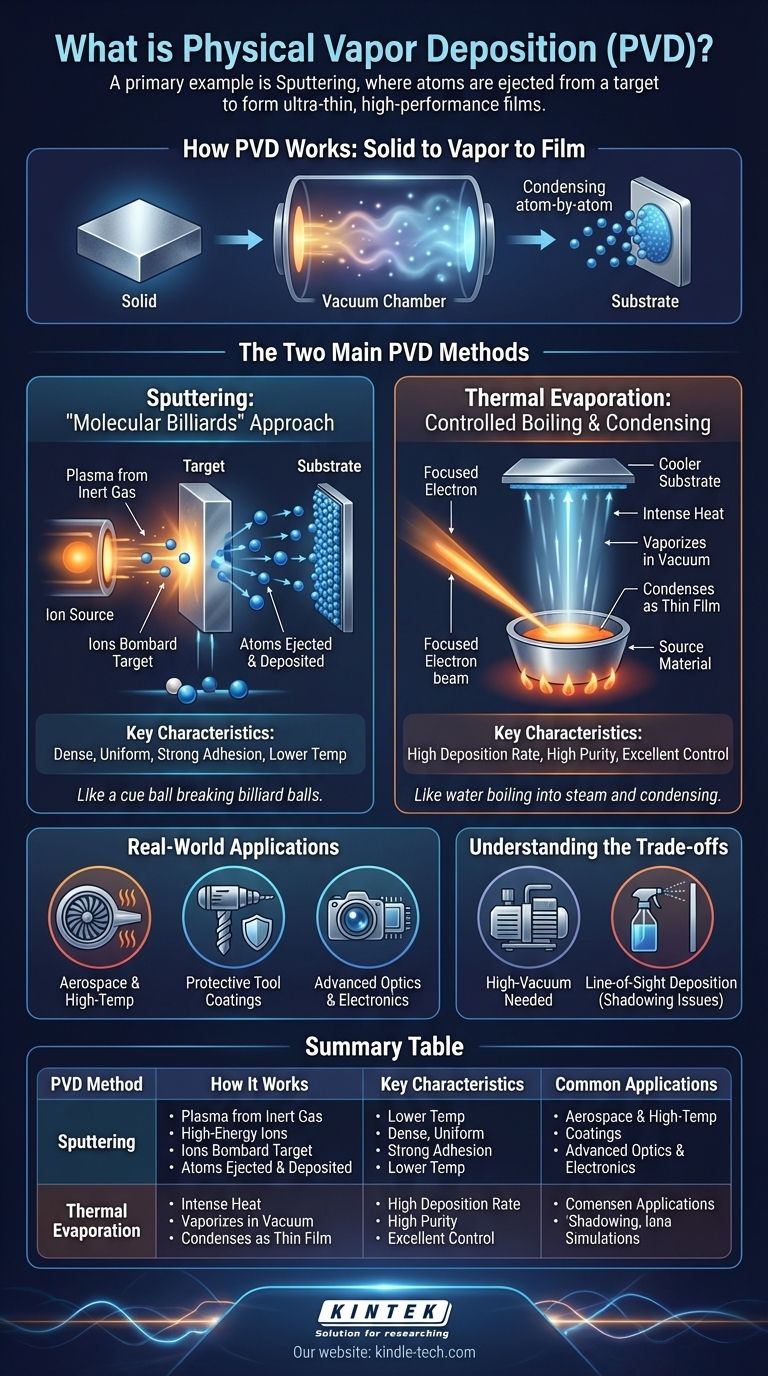

How PVD Works: From Solid to Vapor to Film

At its heart, PVD is a process of physical transformation. A solid material is converted into a vapor within a high-vacuum chamber, transported across that vacuum, and then condensed atom-by-atom onto the surface of a target object, known as a substrate.

The Two Main PVD Methods

While there are many variations, the techniques fall into two primary categories based on how the solid material is turned into a vapor.

Sputtering: A "Molecular Billiards" Approach

Sputtering uses a high-energy source to create a plasma (typically from an inert gas like argon) within the vacuum chamber.

These high-energy ions are accelerated into a "target," which is a block of the desired coating material. The impact physically knocks atoms loose from the target, a process analogous to a cue ball breaking a rack of billiard balls.

These ejected atoms then travel through the chamber and deposit onto the substrate, forming a very dense, uniform, and well-adhered thin film.

Thermal Evaporation: Controlled Boiling and Condensing

Thermal evaporation uses intense heat to raise the temperature of the source material until it begins to vaporize or boil.

This process must happen in a vacuum to allow the vaporized atoms to travel freely without colliding with air molecules.

The vapor then travels in a straight line until it reaches the cooler substrate, where it condenses back into a solid state, forming a thin film. A common method, electron-beam evaporation, uses a focused beam of electrons to heat the material with extreme precision.

Real-World Applications: Where PVD Is Used

PVD is not used for everyday coatings like paint. It is a high-performance process reserved for applications where surface properties are critical to function and longevity.

Aerospace and High-Temperature Components

Aerospace companies use PVD to apply dense, thermal-barrier coatings to engine components like turbine blades. These coatings allow the parts to withstand extreme temperatures, improving efficiency and durability.

Protective Coatings for Tools

Hard, corrosion-resistant coatings are applied to industrial tools like drill bits, end mills, and molds. A thin PVD film can dramatically increase the tool's lifespan by reducing friction and preventing wear.

Advanced Optics and Electronics

PVD is essential for modern electronics and optics. It's used to apply anti-reflective films on eyeglass lenses and camera optics, as well as conductive layers for solar panels and the intricate thin films required for manufacturing semiconductors.

Understanding the Trade-offs

While powerful, PVD is a specialized process with specific constraints that make it unsuitable for some applications.

The Need for a Vacuum

All PVD processes require a high-vacuum environment. The equipment is complex and expensive, and creating the vacuum adds time and cost to the manufacturing cycle.

Line-of-Sight Deposition

The vaporized atoms travel in a straight line from the source to the substrate. This "line-of-sight" characteristic can make it challenging to coat the interior surfaces or complex, shadowed areas of a three-dimensional object uniformly.

Sputtering vs. Evaporation

Sputtering generally produces denser films with stronger adhesion than evaporation. However, evaporation can often achieve higher deposition rates, making it faster for certain applications.

Making the Right Choice for Your Goal

The best PVD technique depends entirely on the desired properties of the final product and the nature of the substrate being coated.

- If your primary focus is maximum durability and wear resistance: Sputtering is often preferred for creating dense, hard coatings on tools and mechanical components.

- If your primary focus is high-purity optical or electronic films: Thermal evaporation provides excellent control for depositing thin, precise layers for lenses or semiconductors.

- If your primary focus is coating a heat-sensitive substrate: Sputtering is often a lower-temperature process than thermal evaporation, making it a safer choice for plastics or other materials that could be damaged by high heat.

Ultimately, PVD empowers engineers to design surfaces with properties far beyond what the base material alone could provide.

Summary Table:

| PVD Method | How It Works | Key Characteristics | Common Applications |

|---|---|---|---|

| Sputtering | Bombards a target material with ions to eject atoms. | Dense, uniform films; strong adhesion; lower temperature. | Protective tool coatings, wear-resistant surfaces. |

| Thermal Evaporation | Heats a material until it vaporizes in a vacuum. | High deposition rates; excellent for high-purity films. | Optical coatings, semiconductor layers, electronics. |

Need a high-performance PVD coating solution for your project? KINTEK specializes in advanced lab equipment and consumables for precise thin-film deposition. Whether you're developing tools, optical components, or electronic devices, our expertise in PVD technologies like sputtering and evaporation can help you achieve superior surface properties. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Anti-Cracking Press Mold for Lab Use

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the CVD method briefly? A Guide to High-Purity Thin Film Deposition

- How does a hollow-type dielectric window compare to a planar quartz window? Boost Plasma CVD Uniformity

- Why are graphite sample holders chosen to support silicon substrates? Key Benefits for Al2TiO5 Coating Purity.

- What is the process of LPCVD? Master High-Purity, Uniform Thin-Film Deposition

- How are high-temperature reaction furnaces used in the coating of regenerated graphite for improved anode performance?

- What are the characteristics of thin films? Harnessing Unique Properties for Advanced Applications

- What is the process of physical deposition? A Guide to High-Purity Thin Film Coating

- What is thermally activated CVD? The Essential Guide to High-Temperature Thin Film Deposition