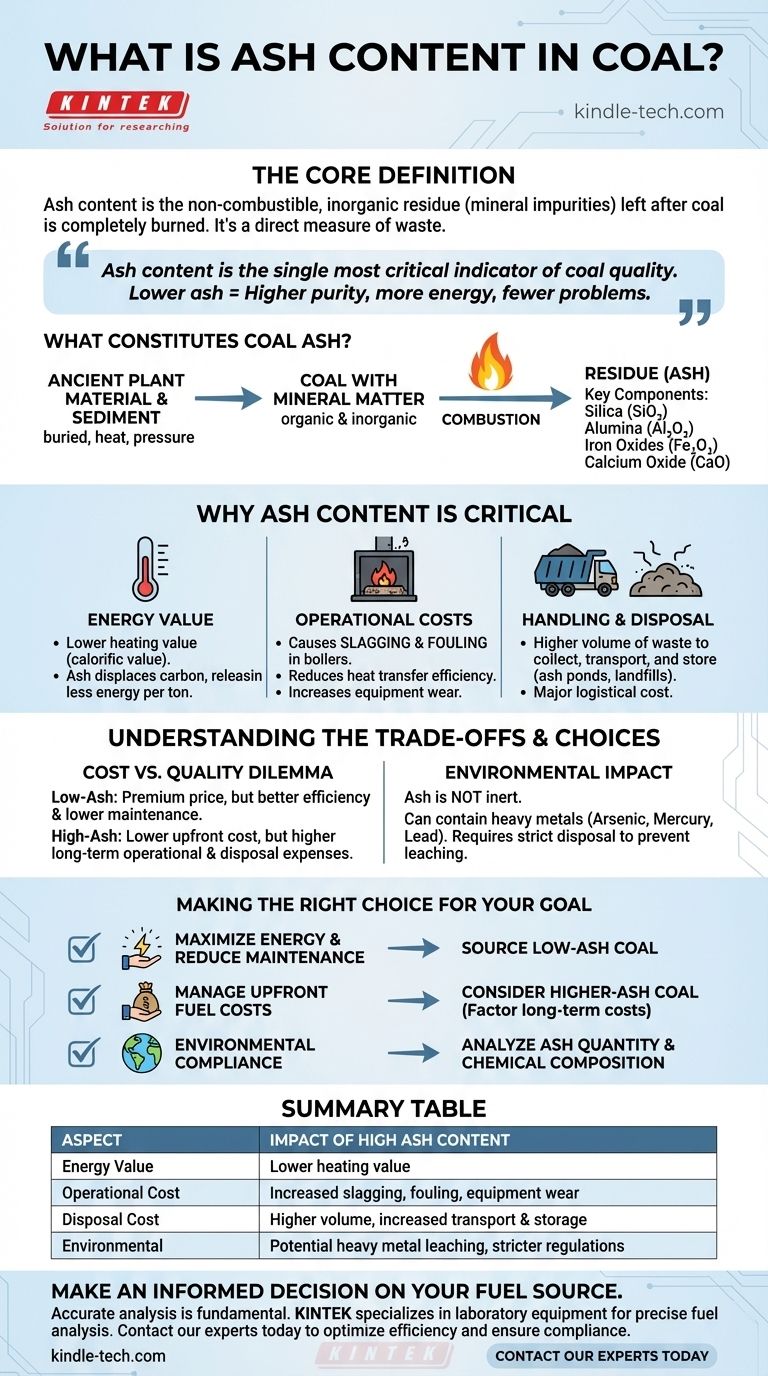

In the simplest terms, the ash content of coal is the measure of the non-combustible, inorganic residue that remains after the coal is completely burned. It is essentially a direct measurement of the mineral impurities within the fuel. These impurities do not contribute to the heating process and are left behind as waste.

The core takeaway is that ash content is the single most critical indicator of coal quality. A lower ash percentage signifies a higher-purity fuel that produces more energy, creates fewer operational problems, and is easier to manage environmentally.

What Constitutes Coal Ash?

To understand its impact, we first need to understand what ash is made of and where it comes from. Coal is not a pure substance; it's a complex fossil fuel with embedded mineral matter.

The Origin of Impurities

Coal forms from ancient plant material that was buried and subjected to immense heat and pressure. During their life, these plants absorbed minerals from the soil and water. This inorganic mineral matter, along with sediment that mixed with the plant debris, became trapped within the coal seam.

Key Chemical Components

When coal is burned, the organic part (carbon and hydrocarbons) provides energy. The inorganic mineral matter does not burn. Instead, it undergoes chemical changes at high temperatures, leaving a residue composed primarily of oxides like silica (SiO₂), alumina (Al₂O₃), iron oxides (Fe₂O₃), and calcium oxide (CaO).

Why Ash Content Is a Critical Metric

The percentage of ash in coal directly affects its performance, cost-effectiveness, and environmental footprint. It is a key specification in any coal supply contract for industrial or power generation use.

Impact on Energy Value

The most direct consequence of high ash content is a lower heating value, also known as calorific value. Ash is inert material that displaces the combustible carbon in the coal. Therefore, a ton of high-ash coal contains less fuel and will release less energy when burned.

Operational and Maintenance Costs

High ash content creates significant operational burdens. The ash can melt at high boiler temperatures, forming molten slag that coats boiler tubes. This slagging and fouling reduces heat transfer efficiency and can cause expensive damage and downtime for cleaning. The abrasive nature of ash particles also increases wear and tear on coal handling and grinding equipment.

Handling and Disposal Challenges

All the ash produced must be collected and disposed of, which is a major logistical and financial challenge. Higher ash content means a greater volume of waste to transport and store, typically in ash ponds or landfills, increasing overall operational costs.

Understanding the Trade-offs

While low-ash coal is always technically superior, the choice of fuel often involves balancing performance with economics and regulatory pressures.

The Cost vs. Quality Dilemma

Low-ash coal is a more valuable, premium product and commands a higher price. End-users must constantly weigh the higher upfront cost of this superior fuel against the long-term operational savings it provides through better efficiency, reduced maintenance, and lower disposal fees.

Environmental Impact

Coal ash is not inert waste. It can contain trace amounts of heavy metals like arsenic, mercury, and lead. The management and disposal of this ash are heavily regulated to prevent these substances from leaching into groundwater and contaminating the surrounding environment.

Measurement and Consistency

The ash content can vary significantly, not just between different coal mines but even within different sections of a single coal seam. This variability makes consistent and frequent testing essential for both coal producers and consumers to ensure quality control and fair pricing.

Making the Right Choice for Your Goal

The acceptable ash content in coal is determined entirely by the specific application, the design of the combustion equipment, and the economic priorities of the operation.

- If your primary focus is maximizing energy efficiency and reducing maintenance: You must source low-ash coal, as it delivers more energy per unit and significantly reduces boiler slagging and fouling.

- If your primary focus is managing upfront fuel costs: You may consider higher-ash coal, but it is critical to factor in the increased long-term costs of ash handling, disposal, and accelerated equipment wear.

- If your primary focus is environmental compliance: You must analyze not just the quantity of ash, but also its specific chemical composition to ensure the safe and legal disposal of potentially hazardous elements.

Ultimately, analyzing ash content is fundamental to making informed economic and operational decisions in any process that relies on coal.

Summary Table:

| Aspect | Impact of High Ash Content |

|---|---|

| Energy Value | Lower heating value (calorific value) |

| Operational Cost | Increased boiler slagging, fouling, and equipment wear |

| Disposal Cost | Higher volume of waste for transport and storage |

| Environmental | Potential for heavy metal leaching; stricter disposal regulations |

Make an informed decision on your fuel source.

Understanding coal ash content is critical for optimizing your operation's efficiency and managing costs. KINTEK specializes in providing the laboratory equipment and consumables needed for precise fuel analysis, helping you accurately measure ash content and other key quality indicators.

Contact our experts today to discuss how our solutions can help you select the right coal for your specific needs, improve your combustion process, and ensure regulatory compliance.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the use of muffle furnace in food laboratory? Essential for Accurate Nutritional Analysis & Quality Control

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- How do you take care of a muffle furnace? Extend Equipment Life and Ensure Accurate Results

- How is a muffle furnace used for sample digestion? A Guide to Dry Ashing for Accurate Analysis

- What are the uses of muffle furnaces? Achieve Precise, Contamination-Free High-Temperature Processing