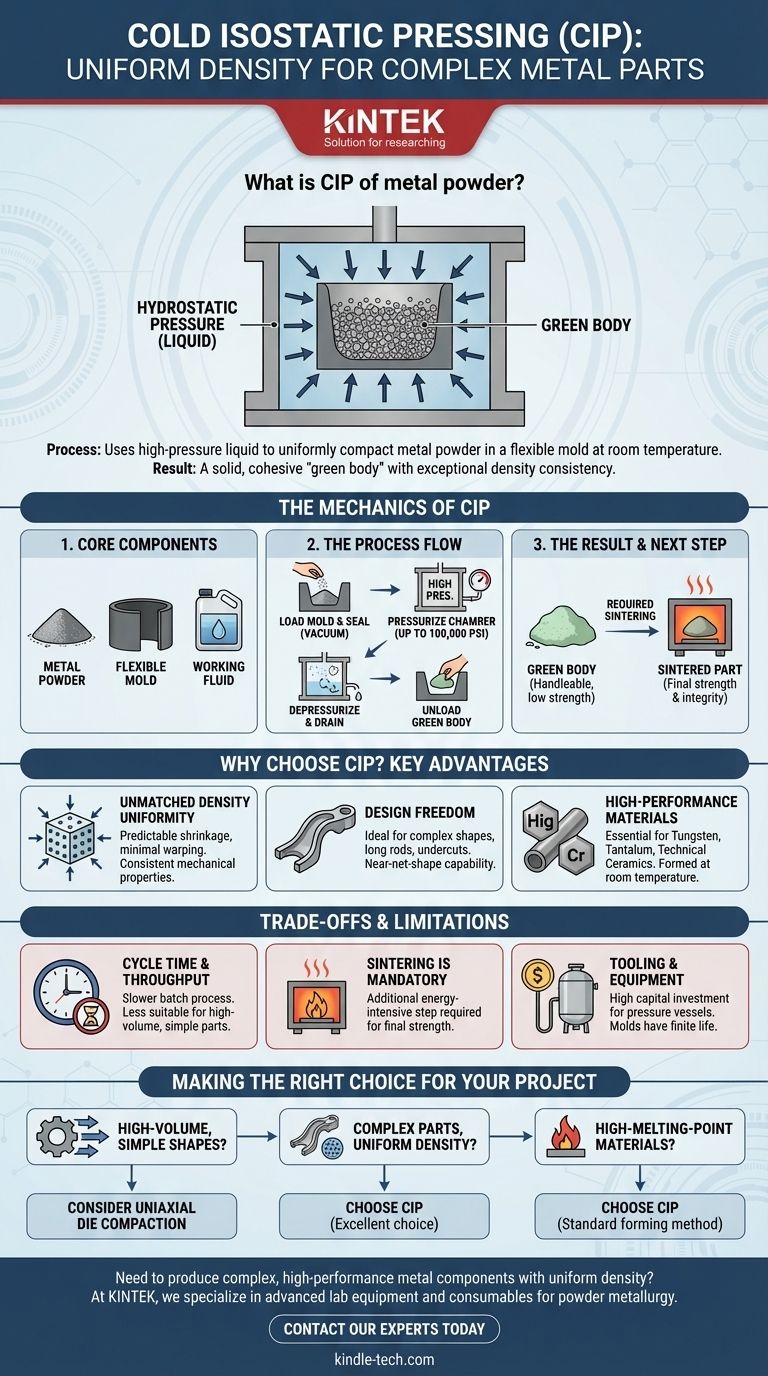

In short, Cold Isostatic Pressing (CIP) is a powder metallurgy process that uses a high-pressure liquid to uniformly compact metal powder inside a flexible mold at room temperature. By applying pressure equally from all directions, CIP creates a solid, cohesive component—known as a "green body"—with exceptionally consistent density throughout its structure.

The defining characteristic of CIP is its use of hydrostatic pressure. Unlike mechanical presses that apply force from one or two directions, CIP's all-encompassing pressure minimizes internal stresses and structural flaws, making it ideal for creating complex parts or components from high-performance materials.

The Mechanics of Cold Isostatic Pressing

To understand why CIP is chosen for specific applications, we must first look at how the process works and what makes it unique.

The Core Components: Powder, Mold, and Fluid

The process relies on three key elements. First is the metal powder itself, which will form the final part.

Second is a flexible, elastomer mold, often made of rubber or polyurethane. This mold is a negative of the desired part shape and is what gives the finished component its geometry.

Third is the working fluid, typically water mixed with a corrosion inhibitor or a specialized oil. This liquid is the medium that transmits the immense pressure from the pump to the mold.

The Step-by-Step Process

The CIP cycle is straightforward and methodical. First, the metal powder is loaded into the flexible mold, which is then sealed, often under a vacuum to remove trapped air.

The sealed mold is then placed inside a high-pressure chamber. The chamber is filled with the working fluid and sealed.

An external pump then pressurizes the fluid, sometimes to levels as high as 100,000 psi (approximately 690 MPa). This pressure is transmitted uniformly through the fluid to the flexible mold, compacting the powder within it.

After a set time, the chamber is depressurized, the fluid is drained, and the mold is removed. Because the mold is flexible, it returns to its original shape, allowing for easy removal of the newly formed part.

The Result: The "Green" Body

The output of the CIP process is not a finished component but a "green body". This is a solid object with the consistency of chalk, possessing enough mechanical strength to be handled but lacking the final properties of a dense metal part.

This green body must undergo a subsequent high-temperature process called sintering. During sintering, the part is heated to below its melting point, causing the powder particles to bond and densify, which imparts its final strength and structural integrity.

Why Choose CIP? The Key Advantages

Engineers specify CIP when the final part's performance requirements justify its use over simpler, faster methods.

Unmatched Density Uniformity

The primary benefit of CIP is the creation of a part with highly uniform density. Because pressure is applied from all directions, there are no density gradients, which are common in parts made with uniaxial (top-down) pressing.

This uniformity ensures predictable and minimal shrinkage during the subsequent sintering stage, reducing the risk of warping or cracking. The final sintered part has consistent mechanical properties throughout.

Design Freedom for Complex Shapes

CIP excels at forming parts with complex geometries, such as long, thin rods or components with undercuts. The flexible mold and uniform pressure allow for the creation of near-net-shape parts that would be difficult or impossible to produce with rigid tooling.

Ideal for High-Performance Materials

The process is essential for working with materials that have extremely high melting points, such as tungsten, tantalum, and technical ceramics. CIP allows these materials to be formed into a solid shape at room temperature, which is far more practical and energy-efficient than trying to melt and cast them.

Understanding the Trade-offs and Limitations

While powerful, CIP is not the solution for every powder metallurgy application. Its limitations must be considered.

Cycle Time and Throughput

CIP is typically a batch process, and the cycle of loading, pressurizing, depressurizing, and unloading takes longer than continuous methods like die compaction. This makes it less suitable for very high-volume production of simple parts.

Sintering is Not Optional

It is critical to remember that CIP is just the forming step. The resulting green body has no functional strength on its own. The need for a secondary, energy-intensive sintering process adds cost, time, and complexity to the overall manufacturing workflow.

Tooling and Equipment

The high-pressure vessels required for CIP represent a significant capital investment. Furthermore, the flexible elastomer molds have a finite lifespan and will eventually wear out and need replacement, which is an ongoing operational cost.

Making the Right Choice for Your Project

Selecting the right manufacturing process depends entirely on your project's specific goals for geometry, material, and production volume.

- If your primary focus is high-volume production of simple shapes: CIP may be too slow and costly; consider traditional uniaxial die compaction.

- If your primary focus is creating complex or large components with uniform density: CIP is an excellent choice, providing design freedom and predictable sintering results.

- If your primary focus is working with high-melting-point materials like tungsten or ceramics: CIP is a standard and highly effective forming method to create the green body before the final sintering stage.

By understanding where Cold Isostatic Pressing excels, you can make an informed decision that aligns your manufacturing method with your desired performance outcomes.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Uses high-pressure liquid in a flexible mold at room temperature. |

| Primary Advantage | Creates parts with exceptionally uniform density. |

| Ideal For | Complex shapes, long thin rods, and high-melting-point materials (e.g., tungsten, ceramics). |

| Output | A "green body" that requires subsequent sintering for final strength. |

| Limitation | Slower batch process; not ideal for high-volume, simple parts. |

Need to produce complex, high-performance metal components with uniform density?

At KINTEK, we specialize in providing advanced lab equipment and consumables for powder metallurgy applications. Our expertise can help you determine if Cold Isostatic Pressing is the right solution for your project's unique requirements for geometry, material, and volume.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and ensure the success of your manufacturing process.

Visual Guide

Related Products

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Double Plate Heating Press Mold for Lab

People Also Ask

- What will happen if forging is carried out at very low temperature? Discover the Power of Cold Forging

- What is the use of cold isostatic pressing? Achieve Uniform Density for Superior Parts

- What is isostatic pressing method for ceramics? Achieve Uniform Density for Complex Parts

- What role does a Cold Isostatic Press (CIP) play in aluminum matrix composites? Achieve 90% Density for Better Hot Pressing

- What is a cold isostatic press? Achieve Uniform Powder Compaction for Complex Parts

- What is the significance of using a cold isostatic press (CIP) to achieve pressureless sintering in LLZO? Enhance Density

- What role does Isostatic Pressing play in SiC production? Ensure Precision for Large-Scale Ceramic Heat Exchangers

- What is the meaning of isostatic pressing? Achieve Uniform Density in Complex Parts