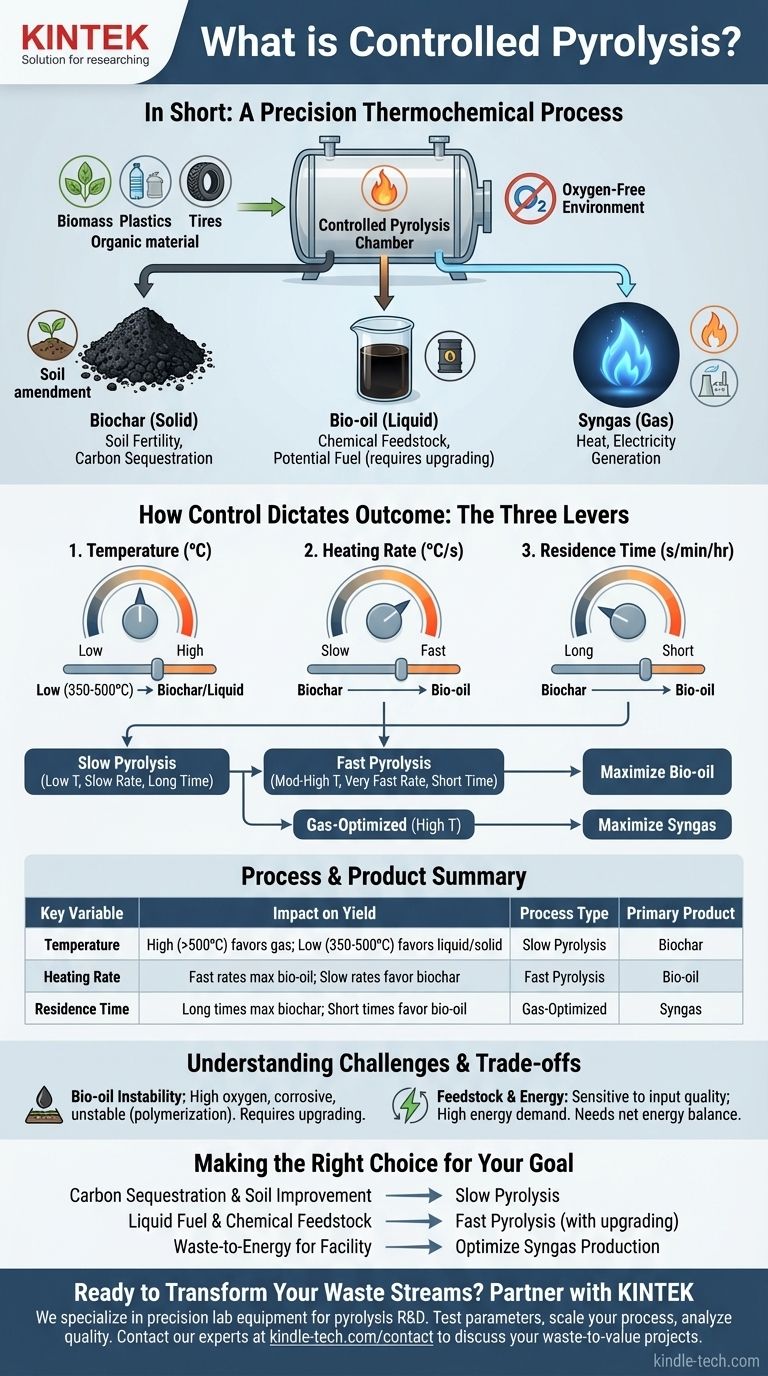

In short, controlled pyrolysis is a thermochemical process that decomposes organic material at high temperatures in a near-complete absence of oxygen. Unlike combustion (burning), which uses oxygen to release energy chaotically, this process carefully manages temperature, heating rate, and time to precisely break down materials like biomass, plastics, or tires into specific, valuable products: a solid (biochar), a liquid (bio-oil), and a gas (syngas).

The fundamental purpose of "control" in pyrolysis is to intentionally steer the chemical decomposition process. By manipulating the conditions, you can decide whether you want to maximize the output of solid, liquid, or gaseous products, effectively turning waste streams into tailored resources.

How Control Dictates the Outcome

The term "controlled" separates this engineered process from simple, uncontrolled heating. The entire goal is to manage three key variables to dictate the end products.

The Critical Role of an Oxygen-Free Environment

The defining feature of pyrolysis is the absence of oxygen. Without oxygen, the organic material cannot combust or burn.

Instead of turning into ash and smoke, the complex organic polymers break down into simpler, smaller molecules, which can be captured as valuable outputs.

The Three Levers of Control

Operators have three primary "levers" to pull to influence the outcome:

- Temperature: Higher temperatures (e.g., >500°C) favor the production of gases, while lower temperatures (e.g., 350-500°C) tend to favor liquids and solids.

- Heating Rate: How quickly the material reaches the target temperature. A very fast rate is key for maximizing liquid bio-oil.

- Residence Time: How long the material is held at the target temperature. Long residence times favor the production of solid biochar.

Connecting Control to the Final Product

By adjusting these levers, we can target specific outcomes.

- Slow Pyrolysis: Low temperatures, slow heating rates, and long residence times (hours or days) maximize the yield of biochar.

- Fast Pyrolysis: Moderate-to-high temperatures, extremely fast heating rates, and very short residence times (seconds) are used to maximize the yield of bio-oil.

The Products of Controlled Pyrolysis

The ability to control the process allows for the creation of three distinct product streams, each with different uses.

Biochar (The Solid)

This stable, carbon-rich solid is similar to charcoal. It is primarily produced via slow pyrolysis.

Biochar is not typically used as a fuel. Instead, its primary value is as a soil amendment to improve fertility and water retention, and for long-term carbon sequestration.

Bio-oil (The Liquid)

Also known as pyrolysis oil, this dark, viscous liquid is the main product of fast pyrolysis. It is a complex mixture of oxygenated organic compounds.

While it has potential as a renewable fuel or chemical feedstock, it is not a direct replacement for petroleum. It requires significant upgrading before it can be used in conventional engines or refineries.

Syngas (The Gas)

The non-condensable gas fraction is a mixture of hydrogen, carbon monoxide, carbon dioxide, and methane.

This "synthesis gas," or syngas, can be combusted immediately on-site to provide the heat needed to run the pyrolysis process itself, or it can be used to generate electricity.

Understanding the Trade-offs and Challenges

While controlled pyrolysis is a powerful technology, its products are not without significant challenges that require further processing.

The Instability of Bio-oil

As noted in industry analysis, bio-oil is fundamentally different from crude oil. It has a high oxygen content, which makes it corrosive to standard pipes and engines.

This oxygenation also means the oil is thermally unstable and can thicken or solidify over time, a process known as polymerization. Furthermore, it is generally immiscible with fossil fuels, preventing simple blending.

These factors mean bio-oil must undergo costly upgrading—typically by removing oxygen—before it can serve as a true "drop-in" fuel.

Feedstock and Energy Demands

The process is sensitive to the type and moisture content of the input material, requiring careful preparation and sorting of the feedstock.

Furthermore, reaching and maintaining high temperatures requires a significant energy input. An efficient system must be designed to use the syngas it produces to power itself, creating a positive net energy balance.

Making the Right Choice for Your Goal

The optimal pyrolysis strategy depends entirely on your desired end product.

- If your primary focus is carbon sequestration or soil improvement: Pursue slow pyrolysis to maximize the production of stable, solid biochar.

- If your primary focus is creating a liquid fuel or chemical feedstock: Implement fast pyrolysis to maximize bio-oil yield, but plan for the necessary secondary upgrading processes.

- If your primary focus is waste-to-energy for a local facility: Design the system to optimize syngas production, which can be immediately used to generate heat and power.

Ultimately, controlled pyrolysis offers a precise and adaptable method for transforming low-value organic waste into high-value, specialized products.

Summary Table:

| Key Variable | Impact on Product Yield |

|---|---|

| Temperature | High (>500°C) favors gas; Low (350-500°C) favors liquid/solid |

| Heating Rate | Fast rates maximize bio-oil; Slow rates favor biochar |

| Residence Time | Long times maximize biochar; Short times favor bio-oil |

| Process Type | Primary Product |

| Slow Pyrolysis | Biochar |

| Fast Pyrolysis | Bio-oil |

| Gas-Optimized | Syngas |

Ready to Transform Your Waste Streams into Valuable Resources?

At KINTEK, we specialize in precision lab equipment and consumables for pyrolysis research and development. Whether you're optimizing biochar production for soil enhancement, developing bio-oil upgrading processes, or designing efficient syngas systems, our solutions help you achieve precise control over temperature, heating rates, and residence times.

We help you:

- Test and optimize pyrolysis parameters for your specific feedstock

- Scale your process from lab to pilot with reliable equipment

- Analyze product quality and composition with precision instruments

Let's tailor a pyrolysis solution for your goals. Contact our experts today to discuss how KINTEK can support your waste-to-value projects.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is vacuum evaporation in thin film? A Guide to High-Purity PVD Coating

- How long does induction brazing take? Achieve Perfect Joints in Seconds to Minutes

- What is the role of Spark Plasma Sintering (SPS) furnaces in Ti-Nb-Zr alloys? Precision Engineering for Implants

- What are the benefits of metal sintering? Achieve Complex, Cost-Effective Metal Parts

- What is the significance of using high-vacuum heat treatment furnaces and rapid quenching for zirconium alloys?

- What temperature is needed to braze stainless steel? The critical guide to alloy-specific brazing

- What is the importance of using a vacuum drying oven in DMC catalyst prep? Unlock Peak Activity & Stability

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys