Cryogenic grinding of crumb rubber is a size-reduction technique where tire chips are frozen with liquid nitrogen before being mechanically crushed. This process leverages the extreme cold (−196°C) to make the normally elastic rubber hard and brittle, allowing it to be easily shattered into a fine, consistent powder.

The central purpose of cryogenic grinding is to fundamentally change the physical properties of rubber from tough and elastic to brittle and glass-like. This transformation enables a more efficient and precise grinding process, resulting in higher quality, finer particles than traditional methods might allow.

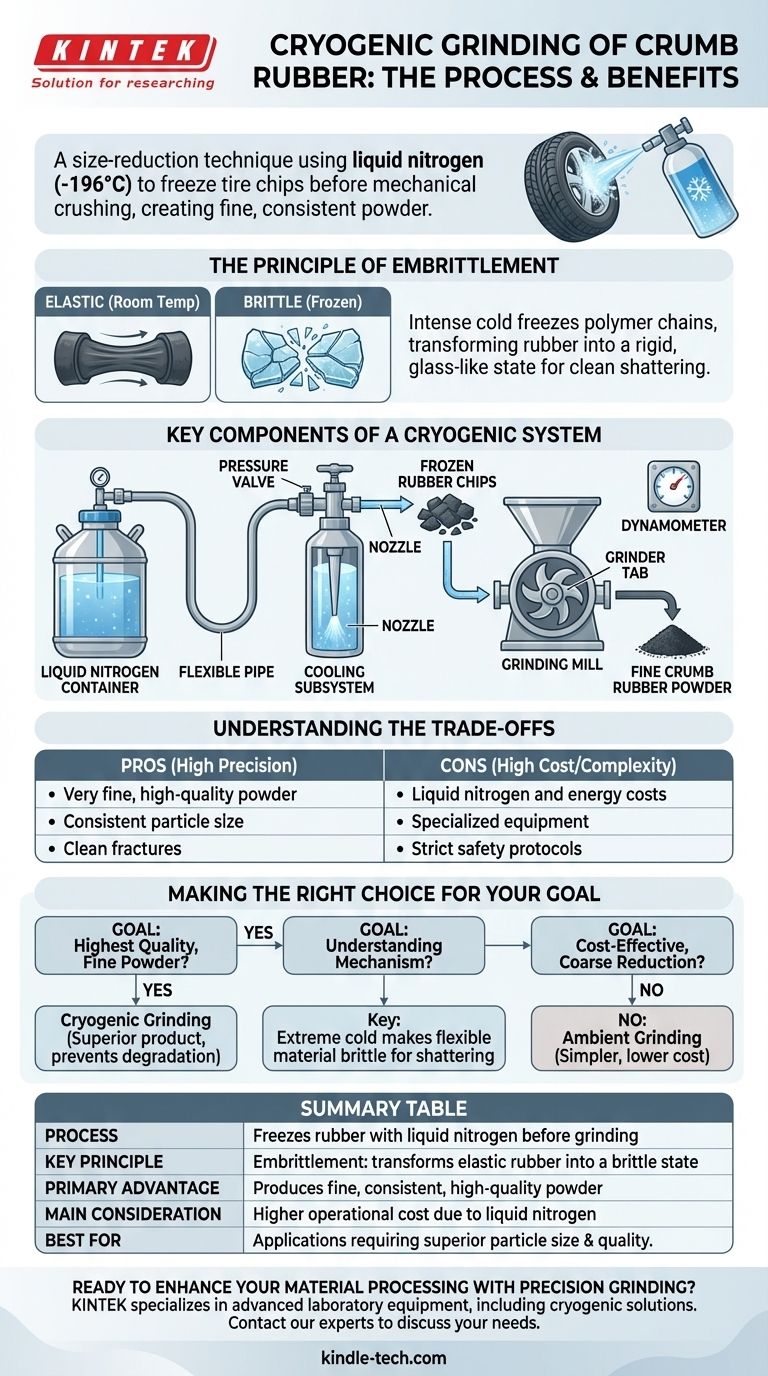

The Principle of Embrittlement

The effectiveness of cryogenic grinding hinges on a simple principle: changing a material's state to make it easier to process.

Shifting from Elastic to Brittle

Room-temperature rubber is known for its elasticity, which makes it durable but difficult to grind into a fine powder. It tends to tear or melt from the friction of grinding rather than break cleanly.

The Role of Liquid Nitrogen

By immersing the tire chips in liquid nitrogen, their temperature is rapidly lowered. This intense cold freezes the polymer chains within the rubber, locking them in place and transforming the material into a rigid, brittle state, much like glass.

The Crushing Stage

Once embrittled, the frozen rubber chips are fed into a grinder or mill. Because the material is no longer elastic, the mechanical impact shatters it cleanly and efficiently into very small, uniform particles, creating the desired crumb rubber powder.

Key Components of a Cryogenic System

A cryogenic grinding setup integrates a cooling system with a mechanical grinder to achieve its goal.

The Cooling Subsystem

This part of the process is responsible for delivering the extreme cold. It typically includes a liquid nitrogen container, along with a pressure valve, pressure gauge, and nozzle to precisely control and apply the cryogen to the rubber.

The Grinding Mechanism

This is the mechanical heart of the system. A grinder tab or similar milling component applies the physical force needed to shatter the frozen, brittle rubber chips into a fine powder.

Supporting Equipment

Other components like a flexible pipe are used to safely transport the liquid nitrogen. A dynamometer may also be included to measure the force and energy consumption of the grinding process, helping to optimize efficiency.

Understanding the Trade-offs

While highly effective, cryogenic grinding involves specific considerations that are important to understand.

High Precision vs. High Cost

This method produces a very fine, high-quality powder with consistent particle size, which is a major advantage. However, the cost of liquid nitrogen and the energy required to maintain such low temperatures can make it more expensive than ambient (room-temperature) grinding methods.

Material Suitability

Cryogenic grinding is exceptionally well-suited for polymers like rubber and plastics that undergo a distinct transition to a brittle state when frozen. It is less effective or necessary for materials that are already hard and brittle at room temperature.

Operational Complexity

Handling liquid nitrogen requires specialized equipment and strict safety protocols. The technical requirements for operating and maintaining a cryogenic system are more demanding than those for simpler mechanical grinders.

Making the Right Choice for Your Goal

- If your primary focus is producing the highest quality, finest rubber powder: Cryogenic grinding is the superior method because it ensures clean particle fractures and prevents thermal degradation of the material.

- If your primary focus is understanding the core mechanism: The key is that extreme cold is used to make a flexible material brittle, which is the necessary pre-condition for shattering it into a fine powder.

- If your primary focus is cost-effective, coarse size reduction: A simpler, ambient grinding process may be a more suitable choice, as it avoids the high costs associated with liquid nitrogen.

Ultimately, cryogenic grinding is a sophisticated solution designed to overcome the inherent toughness of materials like rubber to achieve a superior end product.

Summary Table:

| Aspect | Cryogenic Grinding |

|---|---|

| Process | Freezes rubber with liquid nitrogen (-196°C) before grinding |

| Key Principle | Embrittlement: transforms elastic rubber into a brittle, glass-like state |

| Primary Advantage | Produces fine, consistent, high-quality powder with clean particle fractures |

| Main Consideration | Higher operational cost due to liquid nitrogen and specialized equipment |

| Best For | Applications requiring superior particle size and quality, like advanced recycling |

Ready to enhance your material processing with precision grinding?

KINTEK specializes in advanced laboratory equipment, including solutions for cryogenic processes. Our expertise can help you achieve the fine, consistent rubber powder your projects demand.

Contact our experts today to discuss how we can support your laboratory's specific needs in size reduction and material science.

Visual Guide

Related Products

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Powerful Plastic Crusher Machine

- Laboratory Jaw Crusher

- High Performance Laboratory Freeze Dryer for Research and Development

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is sample pulverizing? The Key to Accurate and Reliable Lab Analysis

- What are the different types of grinding mills? Match the Mechanism to Your Material for Optimal Size Reduction

- What is the difference between grinding and pulverizing? Achieve the Perfect Particle Size for Your Application

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- What is a ceramic mill? A Guide to Rust-Proof, Flavor-Pure Grinding