In materials science and semiconductor manufacturing, a Chemical Vapor Deposition (CVD) chamber is a highly controlled vacuum environment designed for a single purpose: to grow a solid, high-performance thin film on a surface. It functions as a reactor where volatile precursor gases are introduced, react, and decompose, depositing a layer of material atom by atom onto a heated object, known as a substrate. This process is fundamental to creating the advanced materials used in computer chips, solar cells, and protective coatings.

A CVD chamber is not merely a container; it is a precision instrument engineered to precisely manipulate temperature, pressure, and gas chemistry. Its design is entirely focused on creating the perfect conditions for a specific chemical reaction to occur on a substrate's surface, resulting in a new, engineered material.

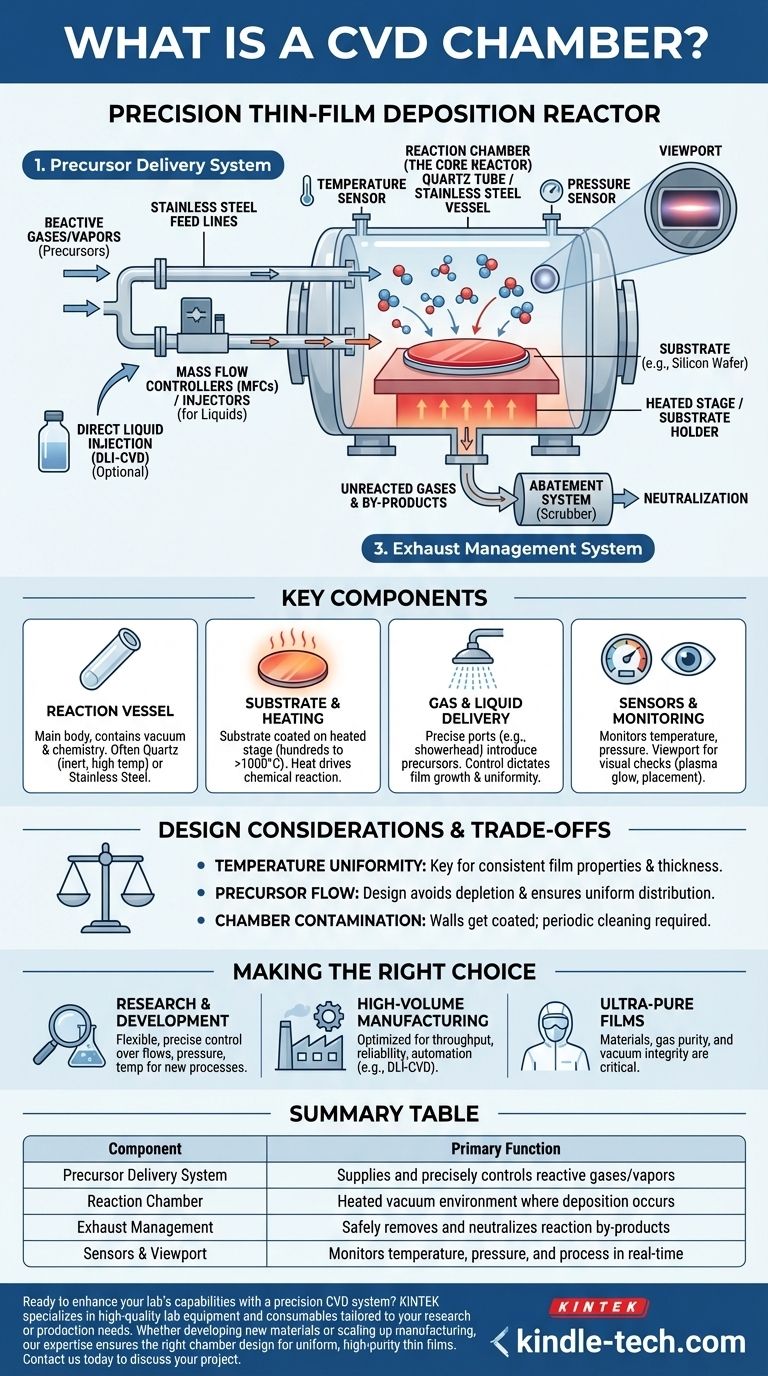

The CVD System: A Three-Part Process

To understand the chamber, you must see it as the core of a larger, integrated system. A complete CVD setup is typically composed of three critical sections that work in sequence.

1. Precursor Delivery System

This is the source of the raw materials. The system delivers reactive gases or vapors, called precursors, into the chamber.

Stainless steel feed lines carry the gases, and mass flow controllers (MFCs) are used to regulate their flow rates with extreme precision. This control is essential for defining the final film's chemical composition and properties.

In some designs, like Direct Liquid Injection (DLI-CVD), the precursor is a liquid that is injected and vaporized, which can allow for higher deposition rates.

2. The Reaction Chamber (The Core Reactor)

This is the heart of the operation where the deposition happens. The chamber itself is typically a quartz tube or a stainless steel vessel built to withstand high temperatures and vacuum conditions.

Inside, a substrate (such as a silicon wafer) is placed on a holder that is heated. The combination of high temperature and low pressure primes the precursor gases to react and deposit a solid film onto the substrate.

3. Exhaust Management System

The chemical reactions in a CVD chamber are often incomplete, and the by-products can be toxic, corrosive, or flammable.

The exhaust system safely pumps these unreacted gases and by-products out of the chamber. They are then sent to an abatement system (a "scrubber") to be neutralized before being released.

A Look Inside the Chamber: Key Components

The reaction chamber is an assembly of specialized components, each with a critical role in controlling the deposition environment.

The Reaction Vessel

This is the main body of the chamber, often a quartz tube for high-temperature processes, as quartz is chemically inert and can handle the heat. Its job is to contain the vacuum and the reactive chemistry.

Substrate and Heating Source

The substrate is the object being coated. It rests on a stage that is heated, often to hundreds or even over a thousand degrees Celsius. This heat provides the thermal energy required to drive the chemical reaction on the substrate's surface.

Gas and Liquid Delivery

Ports on the chamber allow for the introduction of precursors. The precise control offered by mass flow controllers for gases or injectors for liquids dictates the film's growth rate and uniformity.

Sensors and Monitoring

To ensure the process runs correctly, the chamber is equipped with sensors for temperature and pressure.

Additionally, many chambers include a viewport. This small, reinforced window provides a direct view of the process, allowing operators to visually monitor for plasma glow, ensure proper placement, and spot issues in real time.

Understanding the Trade-offs and Design Considerations

The design of a CVD chamber is a balance of competing requirements. There is no single "best" design, only the best design for a specific application.

Temperature Uniformity

A key challenge is ensuring the substrate is heated uniformly. Any temperature variation across the surface will cause the film to grow at different rates, resulting in a non-uniform thickness and inconsistent properties.

Precursor Flow and Distribution

How gases are introduced and flow across the substrate is critical. A poorly designed "showerhead" or gas inlet can lead to depletion, where the gas reacts εται at the leading edge of the substrate, starving the trailing edge and causing non-uniformity.

Chamber Contamination

The chamber walls also get coated during deposition. Over time, this unwanted film can flake off and contaminate the substrate, ruining the device. Chambers must be designed for periodic cleaning to manage this reality.

Making the Right Choice for Your Goal

The optimal CVD chamber design is dictated entirely by the intended outcome.

- If your primary focus is research and development: You need a flexible chamber with precise, independent control over gas flows, pressure, and temperature to explore new materials and processes.

- If your primary focus is high-volume manufacturing: Your chamber must be optimized for throughput, reliability, and automation, favoring designs like DLI-CVD that support high deposition rates.

- If your primary focus is creating ultra-pure films: The chamber's construction materials, the purity of the precursor gases, and the integrity of the vacuum system are the most critical factors.

Understanding the CVD chamber as an integrated reactor is the first step toward mastering thin-film deposition.

Summary Table:

| Component | Primary Function |

|---|---|

| Precursor Delivery System | Supplies and precisely controls reactive gases/vapors |

| Reaction Chamber | Heated vacuum environment where deposition occurs |

| Exhaust Management | Safely removes and neutralizes reaction by-products |

| Sensors & Viewport | Monitors temperature, pressure, and process in real-time |

Ready to enhance your lab's capabilities with a precision CVD system? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your research or production needs. Whether you're developing new materials or scaling up manufacturing, our expertise ensures you get the right chamber design for uniform, high-purity thin films. Contact us today to discuss your project and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is the chemical vapour deposition process in MEMS? Build Precise, Multi-Layered Micro-Devices

- What is the growth mechanism of graphene CVD? Unlocking the Secrets of High-Quality Film Synthesis

- What is the dual function of the substrate heater in MW-SWP CVD hBN synthesis? Optimize Your Thin Film Growth

- What is the use of DC sputtering? Deposition of Conductive Thin Films for High-Tech Applications

- What is chemical vapor deposition in gemstones? A Guide to Lab-Grown Diamonds

- What is the function of a high-temperature CVD reactor in TiN/TiC coating? Optimize Tool Durability and Hardness

- What gases are used in CVD? A Guide to Precursor, Carrier, and Reactant Gases

- What is precursor in CVD? The Essential Guide to Chemical Source Selection