In the field of advanced materials, Chemical Vapor Deposition (CVD) is a dominant industrial method for producing graphene. It is a "bottom-up" synthesis process that grows high-quality, single-atom-thick sheets of graphene over large areas by exposing a metal catalyst to a carbon-containing gas at very high temperatures.

While several methods exist to create graphene, Chemical Vapor Deposition (CVD) is the leading strategy for industrial-scale production because it uniquely balances the creation of large, high-quality, single-layer sheets with scalable and cost-effective manufacturing principles.

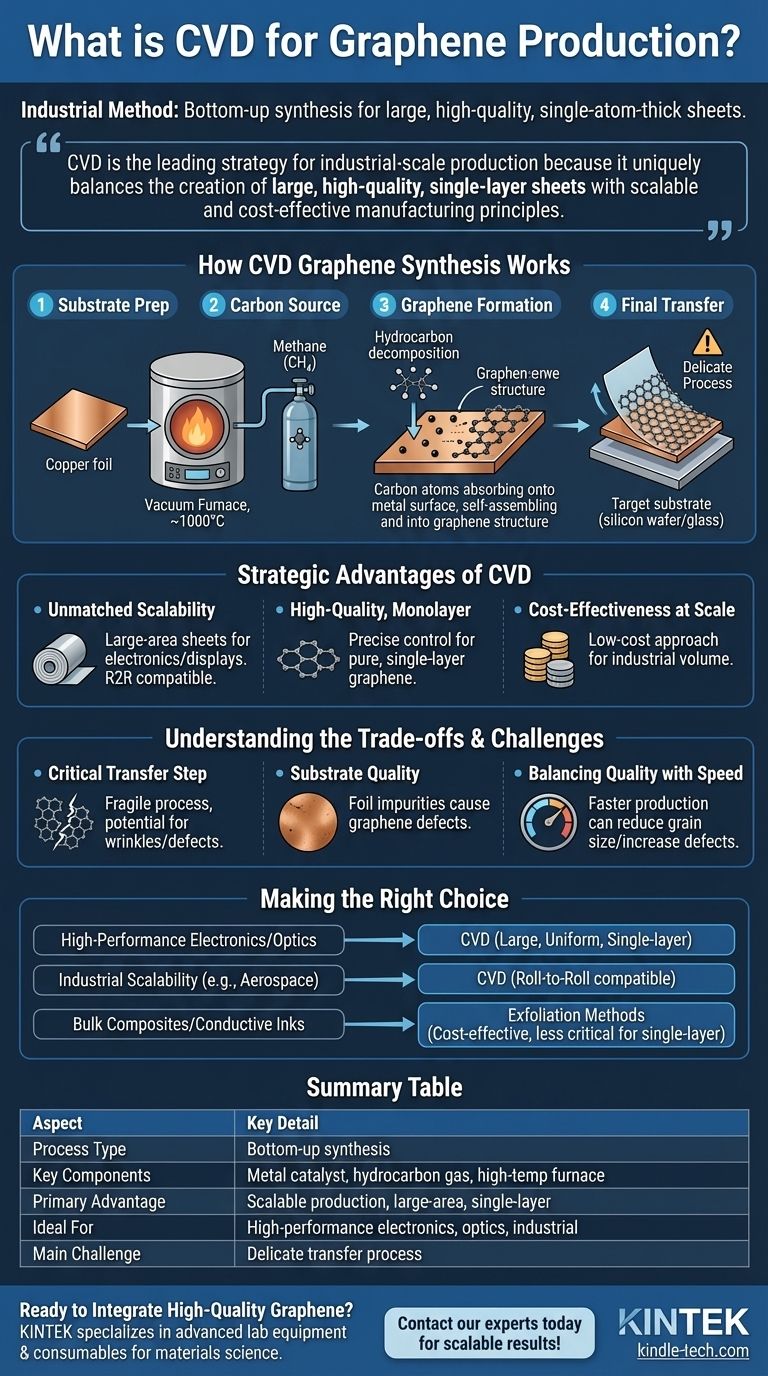

How CVD Graphene Synthesis Works

To understand the significance of CVD, it is essential to grasp its core mechanics. The process is a precise, atom-by-atom assembly rather than the exfoliation of a larger material like graphite.

The Core Principle: Bottom-Up Assembly

The CVD process begins by placing a substrate, typically a thin foil of a catalytic metal like copper or nickel, into a vacuum furnace.

Introducing the Carbon Source

The furnace is heated to approximately 1000°C. A hydrocarbon gas, such as methane, is then introduced into the reaction chamber.

Graphene Formation and Growth

At this extreme temperature, the hydrocarbon gas decomposes. This releases carbon atoms that adsorb, or bind, to the surface of the hot metal foil.

These carbon atoms diffuse across the metal surface, nucleating and self-assembling into the hexagonal lattice structure of graphene. Over time, these small islands of graphene grow and merge to form a continuous, single-atom-thick film covering the substrate.

The Final Transfer Step

Once the graphene layer has formed on the metal foil, it must be carefully transferred to a target substrate (like silicon, glass, or a polymer) where it can be used in a final application.

The Strategic Advantages of CVD

CVD has emerged as the most promising method for commercial graphene production due to a combination of three critical factors.

Unmatched Scalability for Industry

CVD allows for the growth of large-area graphene sheets, which is a fundamental requirement for applications in electronics and displays. The process is compatible with roll-to-roll (R2R) manufacturing, enabling continuous, high-volume production.

High-Quality, Monolayer Production

The process allows for precise control over the final product. By adjusting parameters like gas flow, temperature, and time, manufacturers can reliably produce pure, single-layer graphene, which is essential for its unique electronic and optical properties.

Cost-Effectiveness at Scale

Compared to other methods that can produce high-quality graphene, CVD is considered a relatively low-cost approach when implemented on an industrial scale, making it commercially viable.

Understanding the Trade-offs and Challenges

While powerful, the CVD process is not without its complexities. Acknowledging these challenges is key to successful implementation.

The Transfer Step Is Critical

The process of moving the fragile, one-atom-thick graphene sheet from the metal catalyst to the final substrate is extremely delicate. This step can introduce wrinkles, tears, and contaminants, potentially compromising the material's performance.

Substrate Quality is Paramount

The quality of the final graphene film is directly dependent on the quality of the metal catalyst foil. Any impurities or imperfections on the copper or nickel surface can translate into defects in the graphene's crystal structure.

Balancing Quality with Production Speed

In a roll-to-roll system, there is an inherent trade-off between the speed of production and the crystalline perfection of the graphene. Faster production can sometimes lead to smaller crystal grain sizes or more defects, which must be managed for specific applications.

Making the Right Choice for Your Application

Selecting a graphene production method depends entirely on the end goal. CVD is a superior choice for specific, high-value applications.

- If your primary focus is high-performance electronics or optics: CVD is the definitive method because it produces the large, uniform, single-layer sheets required for these demanding applications.

- If your primary focus is industrial scalability: CVD is the most promising path forward, as its compatibility with roll-to-roll processing makes it the standard for mass production in sectors from aerospace to energy storage.

- If your primary focus is bulk composites or conductive inks: While CVD provides the highest quality, other exfoliation methods might be more cost-effective if single-layer perfection is not the main requirement.

Ultimately, understanding the principles of CVD empowers you to leverage the most powerful method currently available for bringing the potential of graphene from the lab to industrial reality.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process Type | Bottom-up synthesis |

| Key Components | Metal catalyst (e.g., copper), hydrocarbon gas (e.g., methane), high-temperature furnace |

| Primary Advantage | Scalable production of large-area, single-layer graphene |

| Ideal For | High-performance electronics, optics, and industrial applications |

| Main Challenge | Delicate transfer process from catalyst to final substrate |

Ready to Integrate High-Quality Graphene into Your Research or Product Development?

KINTEK specializes in providing the advanced lab equipment and consumables necessary for cutting-edge materials science, including graphene production. Our expertise supports researchers and manufacturers in achieving reliable, scalable results.

Contact our experts today to discuss how our solutions can accelerate your project from concept to reality.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application