At its core, a CVD coating is a thin, high-performance film created on a material's surface through a process called Chemical Vapor Deposition. This technique uses a chemical reaction, rather than simple application, to grow a new layer. Precursor gases are introduced into a high-temperature vacuum chamber where they react and decompose, depositing a solid, highly-adherent coating directly onto the target object.

The crucial distinction to understand is that CVD is not merely applying a layer onto a surface; it is a synthesis process that creates a new, chemically bonded layer on the surface. This results in exceptional adhesion and durability, but its high-temperature nature fundamentally limits the types of materials that can be coated.

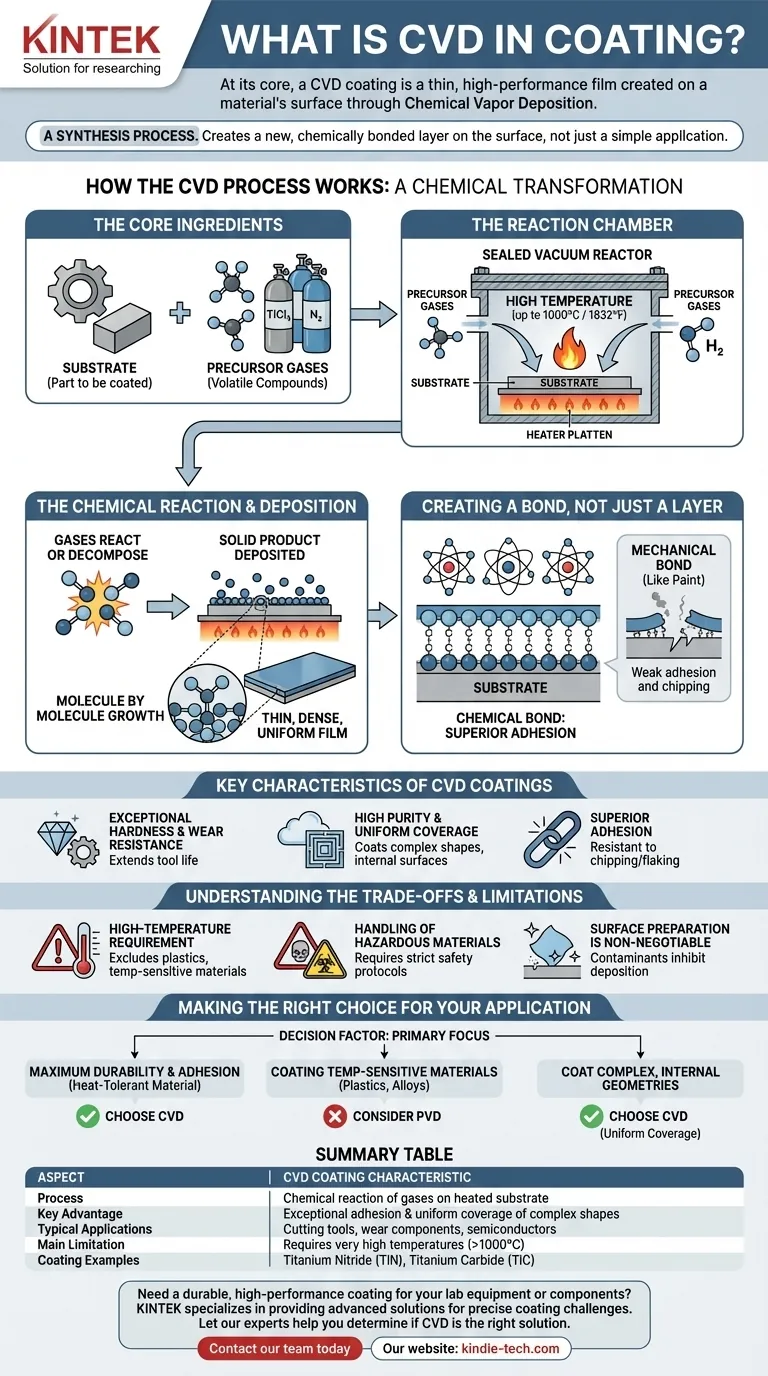

How the CVD Process Works: A Chemical Transformation

Chemical Vapor Deposition is a sophisticated process that transforms volatile gases into a solid, functional coating inside a specialized reactor. It relies on a precise combination of chemistry, heat, and a controlled environment.

The Core Ingredients: Substrate and Precursors

The process begins with two key components: the substrate, which is the part or material to be coated, and the precursor gases. These gases are volatile compounds containing the elements that will make up the final coating.

For example, to create a Titanium Nitride (TiN) coating, gases like Titanium Tetrachloride (TiCl₄), Nitrogen (N₂), and Hydrogen (H₂) are used.

The Reaction Chamber

The substrate is placed inside a sealed vacuum chamber or reactor. The environment is heated to extreme temperatures, often up to 1000°C (1832°F), to provide the necessary energy to drive the chemical reaction.

The Chemical Reaction and Deposition

Once the chamber reaches the target temperature, the precursor gases are introduced. The intense heat causes them to react with each other or decompose. The solid product of this reaction is then deposited, molecule by molecule, onto the heated substrate.

This deposition process "grows" a thin, dense, and uniform film that is integrated directly with the surface of the part.

Creating a Bond, Not Just a Layer

The most significant outcome of the CVD process is the formation of a chemical bond between the coating and the substrate. This is fundamentally different from a mechanical bond (like paint), resulting in superior adhesion that is highly resistant to chipping or flaking.

Key Characteristics of CVD Coatings

The unique nature of the CVD process imparts distinct properties to the resulting films, making them suitable for demanding technical applications.

Exceptional Hardness and Wear Resistance

CVD can produce some of the hardest and most durable coatings available, such as Titanium Carbide (TiC) and Titanium Nitride (TiN). These are commonly used to dramatically extend the life of cutting tools and wear components.

High Purity and Uniform Coverage

Because the coating is built from gaseous reactants, it results in a very high-purity film. Furthermore, the gas can flow around and into complex shapes. This gives CVD a major advantage over "line-of-sight" processes, allowing it to uniformly coat intricate geometries and even internal surfaces.

Superior Adhesion

As mentioned, the chemical bond created during deposition provides adhesion that is typically far superior to other coating methods. The coating becomes an integral part of the substrate's surface.

Understanding the Trade-offs and Limitations

While powerful, CVD is not a universal solution. Its demanding process parameters create significant constraints that are critical to understand.

The High-Temperature Requirement

This is the single greatest limitation of CVD. The extreme heat required for the reaction means that only substrates that can withstand these temperatures without melting, warping, or losing their structural integrity can be coated. This excludes most plastics, many aluminum alloys, and other temperature-sensitive materials.

Handling of Hazardous Materials

The precursor gases used in CVD are often volatile, corrosive, or toxic. The process must be conducted in highly specialized, controlled laboratory or industrial environments with strict safety protocols to manage these risks.

Surface Preparation is Non-Negotiable

For the chemical reaction and bonding to occur properly, the substrate surface must be meticulously cleaned of all contaminants before being placed in the reactor. Any residue can inhibit deposition and compromise the coating's integrity.

Film Thickness and Masking Challenges

Internal stresses can build up in thicker CVD coatings, which limits the achievable film thickness. Additionally, effectively masking off specific areas of a part to prevent them from being coated can be more difficult than with other methods.

Making the Right Choice for Your Application

To decide if CVD is the appropriate process, you must weigh its unique advantages against its demanding requirements.

- If your primary focus is maximum durability and adhesion on a heat-tolerant material: CVD is often the superior choice due to the powerful chemical bond it forms with the substrate.

- If your primary focus is coating temperature-sensitive materials like plastics or certain alloys: You must explore alternative, lower-temperature processes like Physical Vapor Deposition (PVD).

- If you need to coat complex, non-line-of-sight internal geometries: CVD's gas-based deposition provides excellent, uniform coverage where many other methods would fail.

Ultimately, selecting CVD is a strategic decision to invest in a high-performance, chemically integrated surface for applications where failure is not an option.

Summary Table:

| Aspect | CVD Coating Characteristic |

|---|---|

| Process | Chemical reaction of gases on a heated substrate |

| Key Advantage | Exceptional adhesion & uniform coverage of complex shapes |

| Typical Applications | Cutting tools, wear components, semiconductors |

| Main Limitation | Requires very high temperatures (>1000°C) |

| Coating Examples | Titanium Nitride (TiN), Titanium Carbide (TiC) |

Need a durable, high-performance coating for your lab equipment or components?

The unique Chemical Vapor Deposition (CVD) process delivers unparalleled adhesion and uniform coverage, even on complex geometries. KINTEK specializes in providing advanced lab equipment and consumables to meet these precise coating challenges.

Let our experts help you determine if CVD is the right solution for your application. Contact our team today to discuss your specific requirements and discover how our solutions can enhance your project's durability and performance.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance