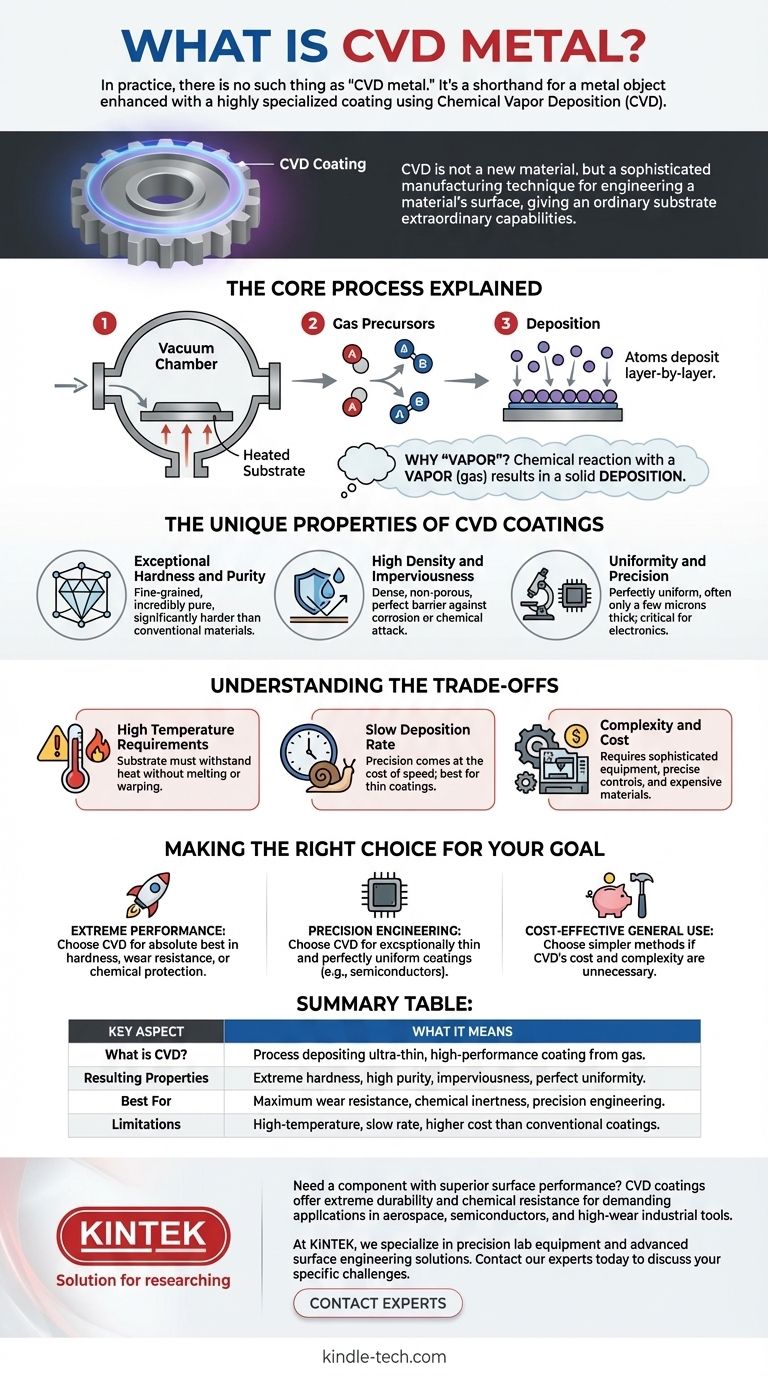

In practice, there is no such thing as "CVD metal." The term is a common shorthand that refers to a metal object that has been enhanced with a highly specialized coating using a process called Chemical Vapor Deposition (CVD). This process does not create a new type of metal; it deposits an ultra-thin, exceptionally pure, and durable film of a different material onto the metal's surface to give it new properties.

The central misunderstanding is thinking of CVD as a material. Instead, you should think of Chemical Vapor Deposition as a sophisticated manufacturing technique for engineering a material's surface, giving an ordinary substrate extraordinary capabilities like superior hardness or chemical resistance.

What is Chemical Vapor Deposition (CVD)?

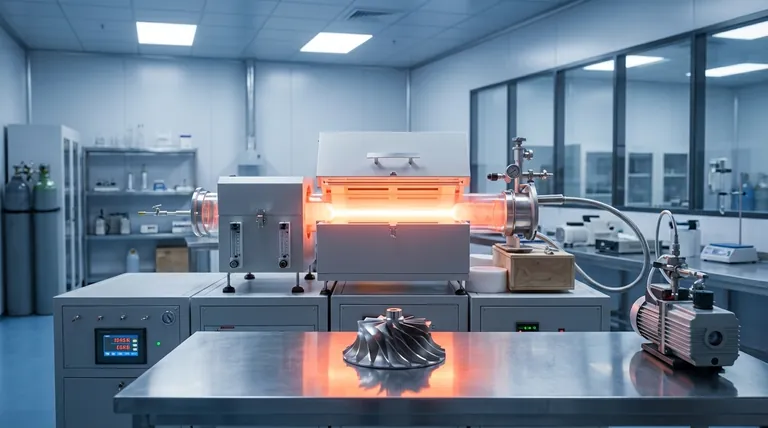

CVD is a process that transforms a gas into a solid, high-performance coating. It is a cornerstone of modern manufacturing for everything from computer chips to jet engine turbines.

The Core Process Explained

The process begins by placing a substrate—the object to be coated, such as a metal part—inside a vacuum chamber. The chamber is heated to a high temperature, and specific precursor gases are introduced. These gases react in the chamber and "deposit" a thin, solid film layer-by-layer onto the surface of the substrate.

The Resulting Film

This method allows for the creation of films with characteristics that are nearly impossible to achieve through other means. The deposited material is not simply painted on; it is grown on the surface atom by atom.

Why "Vapor"?

The name "Chemical Vapor Deposition" is a literal description of the process. A chemical reaction happens with a vapor (gas) that results in a solid deposition on a surface. This use of a gas precursor is what enables the exceptional purity and uniformity of the final coating.

The Unique Properties of CVD Coatings

A surface modified by CVD is fundamentally different from one that is uncoated or coated by conventional means. The properties are derived directly from the atomic-level precision of the deposition process.

Exceptional Hardness and Purity

CVD coatings are characteristically fine-grained, incredibly pure, and significantly harder than even the same materials produced through conventional methods. For example, a CVD ceramic coating on a metal tool makes it far more durable than the tool alone.

High Density and Imperviousness

The deposition process creates a coating that is dense and non-porous. This makes the surface impervious, meaning it forms a perfect barrier against corrosion or chemical attack.

Uniformity and Precision

CVD can apply a perfectly uniform coating that is often only a few microns thick (thinner than a human hair). This precision is critical in industries like electronics, where even a microscopic inconsistency can cause a device to fail.

Understanding the Trade-offs

While powerful, the CVD process is not a universal solution. Its specialized nature comes with specific limitations you must consider.

High Temperature Requirements

CVD typically operates at elevated temperatures. This means the substrate material must be able to withstand the heat without melting, warping, or losing its own structural integrity.

Slow Deposition Rate

The precision of CVD comes at the cost of speed. Deposition rates are quite slow, often measured in microns per hour. This makes the process best suited for thin coatings, not for creating thick, bulk materials quickly.

Complexity and Cost

CVD requires sophisticated vacuum equipment, precise temperature and gas controls, and expensive precursor materials. It is a more complex and costly process than simpler methods like painting or electroplating.

Making the Right Choice for Your Goal

Deciding whether a CVD-coated component is right for you depends entirely on your performance requirements.

- If your primary focus is extreme performance: Use a CVD-coated part when you need the absolute best in hardness, wear resistance, or protection from corrosive chemicals.

- If your primary focus is precision engineering: Choose CVD when you require an exceptionally thin and perfectly uniform coating, as is common in semiconductors and advanced optics.

- If your primary focus is cost-effectiveness for general use: Look to other, simpler coating methods, as the cost and complexity of CVD are unnecessary for less demanding applications.

Understanding this process empowers you to see past the marketing terms and recognize CVD as a powerful tool for engineering surfaces with unparalleled performance.

Summary Table:

| Key Aspect | What It Means |

|---|---|

| What is CVD? | A process that deposits an ultra-thin, high-performance coating from a gas onto a metal surface. |

| Resulting Properties | Extreme hardness, high purity, imperviousness to corrosion, and perfect uniformity. |

| Best For | Applications requiring maximum wear resistance, chemical inertness, or precision engineering. |

| Limitations | High-temperature process, slow deposition rate, and higher cost than conventional coatings. |

Need a component with superior surface performance? The advanced coatings created by CVD can give your metal parts extreme durability and chemical resistance, essential for demanding applications in aerospace, semiconductors, and high-wear industrial tools. At KINTEK, we specialize in precision lab equipment and consumables, including systems for advanced surface engineering. Contact our experts today to discuss how CVD technology can solve your specific material challenges and enhance your product's performance.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory CVD Boron Doped Diamond Materials

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques