In engineering and manufacturing, diamond coatings are used to impart extreme hardness, wear resistance, and low friction onto the surface of other materials. This process enhances the performance and lifespan of critical components in demanding fields like industrial manufacturing, aerospace, and medicine. Applications range from cutting tools that machine abrasive materials to high-performance engine parts and biocompatible medical implants.

The core purpose of a diamond coating is not decorative. It is a strategic engineering decision to transfer the superior physical properties of diamond to a more common or cost-effective base material, radically improving its durability and performance under extreme conditions.

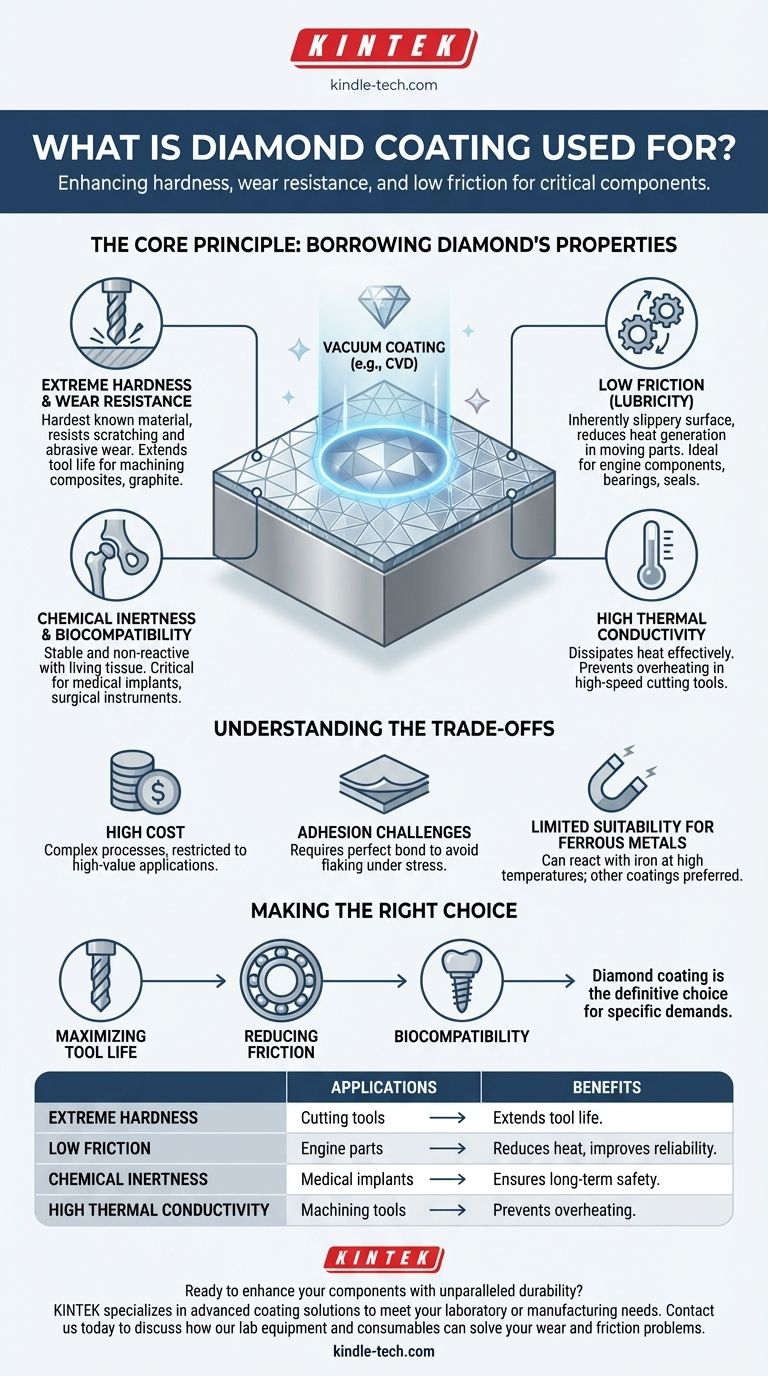

The Core Principle: Borrowing Diamond's Properties

Applying a thin film of diamond—often through a vacuum coating process like Chemical Vapor Deposition (CVD)—allows a component to "borrow" diamond's legendary characteristics without being made entirely of solid diamond, which would be prohibitively expensive and brittle.

Extreme Hardness and Wear Resistance

This is the primary reason for using diamond coatings. Diamond is the hardest known material, making it exceptionally resistant to scratching and abrasive wear.

A coated tool can machine highly abrasive materials like carbon fiber composites, graphite, and high-silicon aluminum for far longer than an uncoated tool.

Low Coefficient of Friction

Diamond surfaces are inherently "slippery," meaning they exhibit very low friction when sliding against other materials.

This property, known as lubricity, reduces heat generation and wear in moving parts. It is invaluable for high-performance engine components, bearings, and mechanical seals.

Chemical Inertness and Biocompatibility

Diamond is chemically stable and does not easily react with other substances. This makes it an ideal protective barrier against corrosion and chemical attack.

This inertness also makes it biocompatible, meaning it is not harmful to living tissue. This is critical for medical applications like joint implants and surgical instruments, where the coating must not degrade or cause an adverse reaction inside the body.

High Thermal Conductivity

Diamond is an excellent thermal conductor, meaning it can dissipate heat very effectively and quickly.

For high-speed cutting tools, this property draws heat away from the cutting edge, preventing it from overheating, losing its hardness, and failing prematurely.

Understanding the Trade-offs

While its benefits are significant, diamond coating is not a universal solution. The choice to use it involves specific technical and economic considerations.

The Challenge of High Cost

The equipment and processes required to create high-quality diamond films are complex and expensive. This cost restricts its use to high-value applications where the performance increase justifies the investment.

The Critical Issue of Adhesion

The single greatest technical challenge is ensuring the diamond film adheres perfectly to the substrate material. If the bond is weak, the coating can delaminate or flake off under stress, rendering it useless.

Significant surface preparation and sophisticated deposition techniques are required to achieve a durable bond, especially on materials like steel.

Limited Suitability for Ferrous Metals

At high temperatures generated during the machining of steel or cast iron, diamond can react with the iron, causing rapid chemical wear. For these applications, other hard coatings like Cubic Boron Nitride (cBN) are often preferred.

Making the Right Choice for Your Goal

Selecting a diamond coating is a decision driven entirely by the performance demands of the application.

- If your primary focus is maximizing tool life in abrasive, non-ferrous materials: Diamond coating is the definitive choice for cutting tools machining composites, graphite, or high-silicon aluminum alloys.

- If your primary focus is reducing friction and wear in high-performance parts: Its exceptional lubricity makes it ideal for critical engine components, precision bearings, and mechanical seals where reliability is paramount.

- If your primary focus is biocompatibility for medical devices: Its chemical inertness makes it a superior option for implants and surgical instruments that require long-term stability and safety within the human body.

Ultimately, choosing a diamond coating is an investment in unparalleled durability for applications where premature failure is not an option.

Summary Table:

| Key Property | Primary Application | Benefit |

|---|---|---|

| Extreme Hardness & Wear Resistance | Cutting tools for abrasive materials (e.g., composites, graphite) | Drastically extends tool life |

| Low Friction (Lubricity) | High-performance engine parts, bearings, seals | Reduces heat and wear, improves reliability |

| Chemical Inertness & Biocompatibility | Medical implants and surgical instruments | Ensures long-term safety and stability in the body |

| High Thermal Conductivity | High-speed machining tools | Prevents overheating and premature failure |

Ready to enhance your components with unparalleled durability? KINTEK specializes in advanced coating solutions, including diamond coatings, to meet the demanding needs of your laboratory or manufacturing process. Our expertise ensures superior adhesion and performance for your cutting tools, medical devices, and high-performance parts. Contact us today to discuss how our lab equipment and consumables can solve your most challenging wear and friction problems!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Laboratory CVD Boron Doped Diamond Materials

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers