In essence, Diamond-Like Carbon (DLC) coating is used as a high-performance surface treatment to drastically reduce friction and increase the wear resistance of critical components. It is applied in demanding environments ranging from motorsport engine parts and industrial cutting tools to medical implants and luxury watches. The coating imparts a unique combination of properties that protect and enhance the underlying material.

The core value of DLC is its duality: it delivers the extreme hardness associated with diamond while providing the low-friction, self-lubricating properties of graphite. This unique combination is why it is used to solve engineering problems where wear, friction, and durability are the primary concerns.

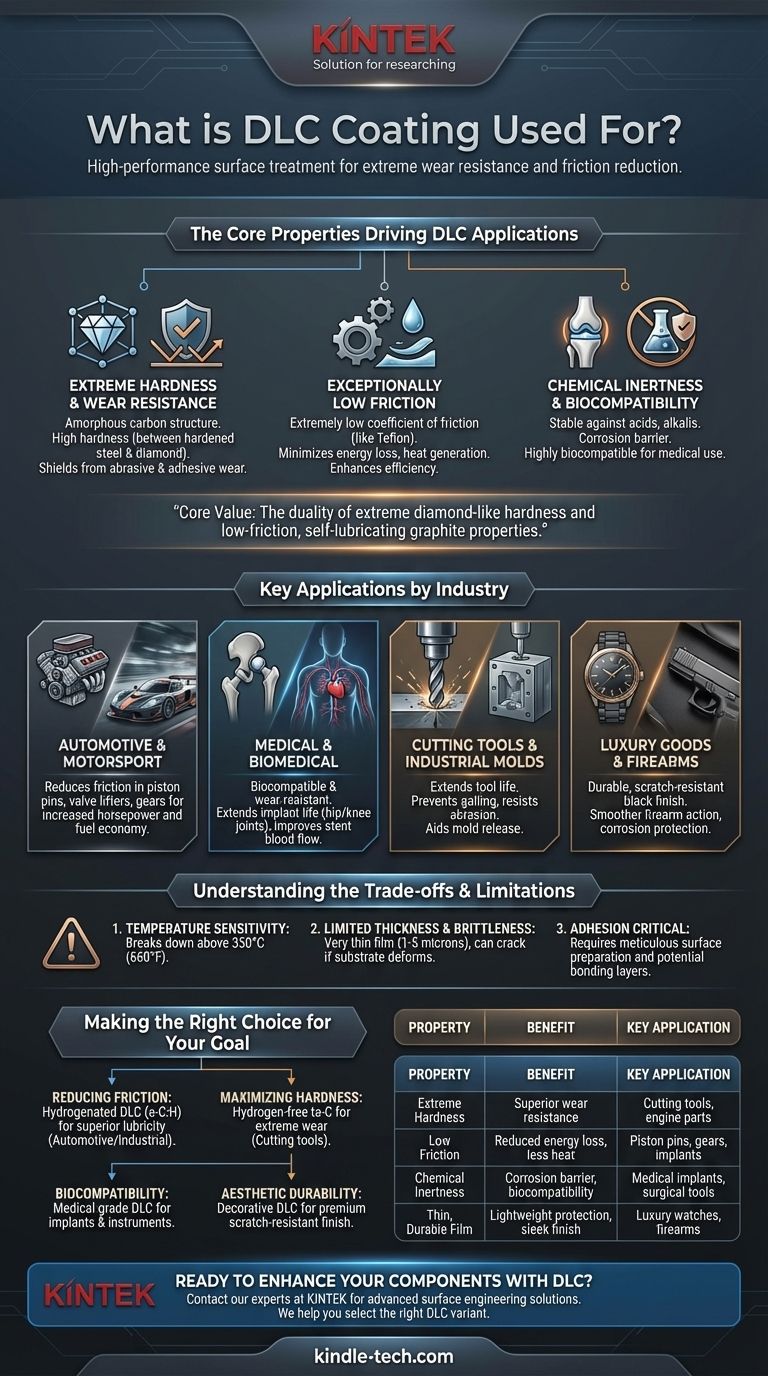

The Core Properties Driving DLC Applications

To understand where DLC is used, you must first understand its fundamental characteristics. The application is always a direct result of one or more of these key properties.

Extreme Hardness and Wear Resistance

DLC is an amorphous carbon material, meaning its atoms lack a rigid crystal structure. This structure gives it a very high hardness, typically falling between that of hardened steel and natural diamond.

This property directly translates into superior resistance to abrasive and adhesive wear. It creates a protective barrier on a component's surface, shielding it from scratches, scuffing, and material loss over time.

Exceptionally Low Friction

One of the most valuable properties of DLC is its extremely low coefficient of friction, often compared to that of Teflon. This inherent lubricity is especially pronounced in hydrogenated forms of DLC (a-C:H).

By reducing friction between moving parts, DLC minimizes energy loss, reduces heat generation, and can even allow systems to operate with less lubrication. This is critical for improving efficiency and preventing component seizure.

Chemical Inertness and Biocompatibility

DLC coatings are chemically stable and do not react with most acids, alkalis, or solvents. This makes them an excellent corrosion barrier, protecting the substrate material from chemical attack.

Furthermore, its carbon base makes it highly biocompatible. The human body generally does not recognize it as a foreign material, minimizing the risk of an adverse immune response. This is a non-negotiable requirement for medical implants.

Key Applications by Industry

These properties enable DLC to solve critical problems across several high-stakes industries.

Automotive and Motorsport

In engines and drivetrains, friction is the enemy of power and efficiency. DLC is applied to components like piston pins, valve lifters, and gears to reduce frictional losses, unlock horsepower, and improve fuel economy. Its durability is essential for withstanding the harsh environment inside an engine.

Medical and Biomedical

Biocompatibility and wear resistance make DLC ideal for medical use. It is applied to orthopedic implants like hip and knee joints to reduce wear debris and extend implant life. It is also used on surgical instruments to maintain a sharp edge and on cardiovascular stents to improve blood flow and reduce clotting.

Cutting Tools and Industrial Molds

For drills, end mills, and taps, DLC extends tool life dramatically. Its low friction prevents chips from welding to the cutting edge (galling), while its hardness resists abrasion from the workpiece. In plastic injection molding, it helps molds release parts more easily and protects them from wear.

Luxury Goods and Firearms

In high-end watches, DLC provides a durable, scratch-resistant finish with a sleek black appearance that is far superior to traditional PVD coatings. Similarly, it is applied to firearm components to reduce friction for smoother action and provide a tough, corrosion-resistant exterior.

Understanding the Trade-offs and Limitations

Despite its advantages, DLC is not a universal solution. Understanding its limitations is crucial for successful application.

Temperature Sensitivity

Most common forms of DLC begin to break down and convert to graphite at temperatures above 350°C (660°F). This limits their use in extremely high-temperature environments, such as on turbocharger components or in certain metal-cutting operations.

Limited Thickness and Brittleness

DLC is a very thin film, typically only 1 to 5 microns thick. It is not designed to fix geometric imperfections or absorb heavy impacts. If the underlying substrate deforms significantly, the hard but brittle coating can crack or delaminate.

Adhesion Is Everything

The performance of the coating is entirely dependent on its bond to the substrate. Meticulous surface preparation, cleaning, and the potential use of intermediate bonding layers are critical. Poor adhesion is the most common cause of coating failure.

Not All "DLC" Is the Same

"DLC" is a family of coatings, not a single material. Variations in hydrogen content (e.g., a-C:H vs. ta-C) and other doping elements result in different balances of hardness, friction, and internal stress. Choosing the wrong type for an application can lead to poor performance.

Making the Right Choice for Your Goal

Selecting the right surface treatment requires matching the technology to the primary problem you need to solve.

- If your primary focus is reducing friction in moving parts: A hydrogenated DLC (a-C:H) is often the best choice for its superior lubricity in automotive or industrial machinery.

- If your primary focus is maximizing hardness for extreme wear: A hydrogen-free tetrahedral amorphous carbon (ta-C) offers the highest hardness and is ideal for cutting tools or components exposed to severe abrasion.

- If your primary focus is biocompatibility and chemical resistance: A medical-grade DLC, certified for its inertness, is the only option for implants and surgical instruments.

- If your primary focus is aesthetic durability: A precisely applied decorative DLC provides a premium, scratch-resistant finish for watches, jewelry, or firearms.

By understanding that DLC excels at managing friction and wear within specific operational limits, you can effectively leverage it to enhance the performance and lifespan of your components.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Extreme Hardness | Superior wear resistance | Cutting tools, engine parts |

| Low Friction | Reduced energy loss, less heat | Piston pins, gears, implants |

| Chemical Inertness | Corrosion barrier, biocompatibility | Medical implants, surgical tools |

| Thin, Durable Film | Lightweight protection, sleek finish | Luxury watches, firearms |

Ready to enhance your components with a high-performance DLC coating?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Our expertise ensures your automotive, medical, or industrial parts achieve maximum durability, reduced friction, and extended lifespan. Let us help you select the right DLC variant for your specific needs.

Contact our experts today to discuss how DLC coating can solve your wear and friction challenges!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance

- Is diamond coating worth it? Maximize Component Life and Performance