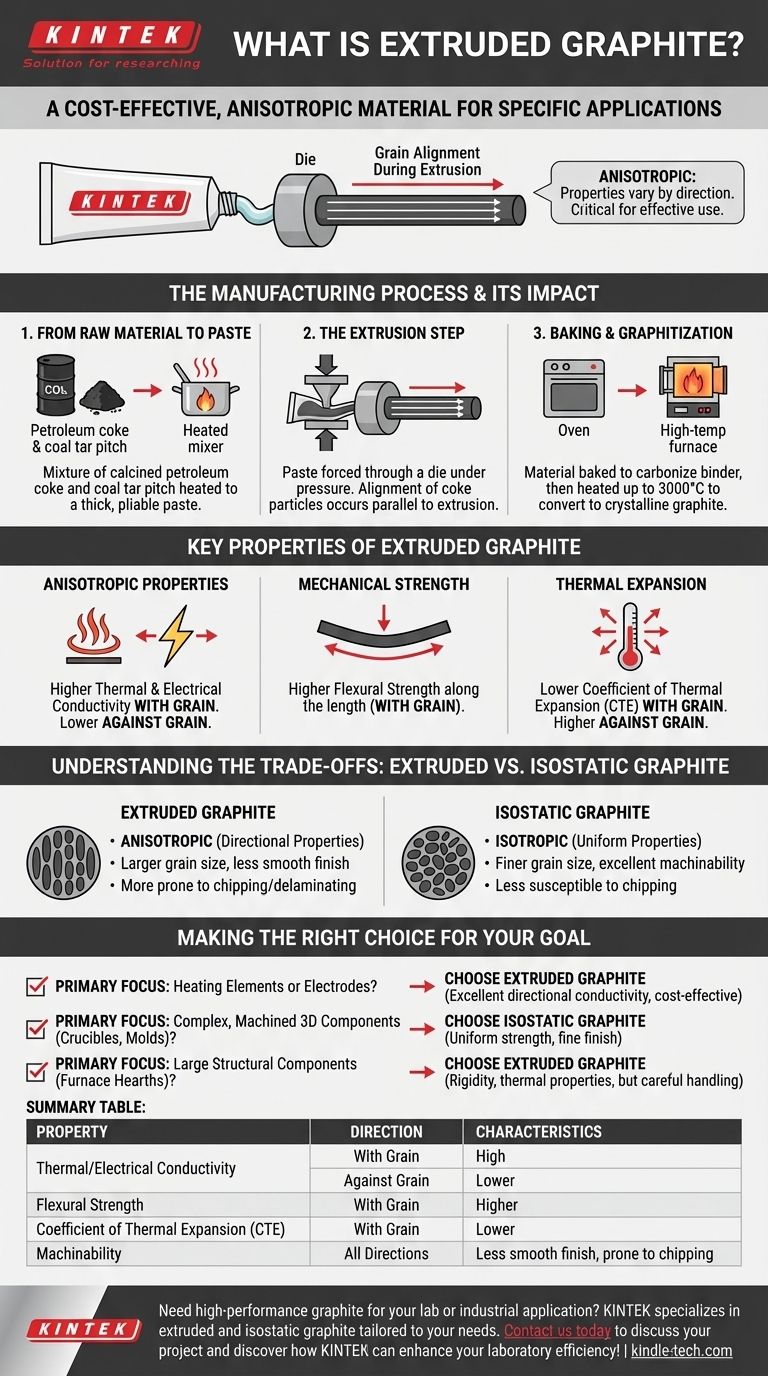

In simple terms, extruded graphite is a common type of synthetic graphite produced by forcing a paste of carbon materials through a shaped die, much like squeezing toothpaste from a tube. This process aligns the material's internal grain structure, giving it distinct directional properties. It is a cost-effective method for creating stock shapes like rods, bars, and plates.

The critical takeaway is that the extrusion process creates an anisotropic material, meaning its properties (like strength and conductivity) are different depending on the direction. Understanding this directional grain is essential for using extruded graphite effectively.

The Manufacturing Process and Its Impact

The unique characteristics of extruded graphite are a direct result of how it is made. The process imparts a distinct "grain" or orientation to the final material.

### From Raw Material to Paste

The process begins with a mixture of calcined petroleum coke (the primary carbon source) and coal tar pitch (a binder). These materials are ground and blended, then heated to a high temperature, creating a thick, pliable paste.

### The Extrusion Step

This hot paste is then forced under immense pressure through a die. The die's shape determines the final cross-section of the product, such as a round rod or a rectangular bar. As the needle-like particles of coke are forced through the die, they align themselves parallel to the direction of extrusion.

### Baking and Graphitization

After extrusion, the "green" material is carefully baked over several weeks to carbonize the pitch binder and lock the structure in place. The final step is graphitization, where the carbon is heated to extremely high temperatures (up to 3000°C), converting the amorphous carbon into a crystalline graphite structure.

Key Properties of Extruded Graphite

The alignment of the coke particles during extrusion is the single most important factor defining the material's behavior.

### Anisotropic Properties

Because the graphite crystals are aligned, properties vary significantly with and against the grain. Thermal and electrical conductivity are much higher when measured parallel to the direction of extrusion (with the grain) than when measured perpendicular to it (against the grain).

### Mechanical Strength

Similarly, mechanical properties like flexural strength are higher along the length of the extruded part. This directional strength is a key design consideration.

### Thermal Expansion

The Coefficient of Thermal Expansion (CTE) is also directional. It is typically lower when measured with the grain and higher when measured against it. This is a critical factor in applications involving high-temperature cycles.

Understanding the Trade-offs: Extruded vs. Isostatic Graphite

Choosing the right type of graphite requires understanding the fundamental trade-offs between manufacturing methods.

### Anisotropy vs. Isotropy

The main alternative to extruded graphite is isostatic graphite (or "iso-molded"). Iso-molded graphite is made by pressing the powder in a mold from all directions, resulting in a random grain orientation. This makes it isotropic, meaning its properties are uniform in all directions.

### Grain Size and Machinability

Extruded graphite generally has a larger grain size compared to finer-grained isostatic grades. This can result in a less smooth machined finish and makes it less suitable for applications requiring intricate detail.

### Susceptibility to Chipping

The aligned grain structure of extruded graphite can make it more prone to chipping or delaminating, especially on sharp edges or during handling. This is particularly relevant for components like furnace hearth rails, where mechanical impact is possible during loading and unloading.

Making the Right Choice for Your Goal

Your application's specific demands will determine whether extruded graphite's directional properties are an advantage or a liability.

- If your primary focus is on applications like heating elements or electrodes: The excellent directional conductivity and cost-effectiveness of extruded graphite make it the ideal choice.

- If your primary focus is on complex, machined 3D components like crucibles or molds: The uniform strength and fine finish of isostatic graphite are necessary for reliable performance.

- If your primary focus is on large structural components like furnace hearths: The rigidity and thermal properties of extruded graphite are beneficial, but its tendency to chip requires careful design and handling protocols.

Ultimately, matching the material's inherent grain structure to the demands of your application is the key to engineering success.

Summary Table:

| Property | Direction | Characteristics |

|---|---|---|

| Thermal/Electrical Conductivity | With Grain | High |

| Thermal/Electrical Conductivity | Against Grain | Lower |

| Flexural Strength | With Grain | Higher |

| Coefficient of Thermal Expansion (CTE) | With Grain | Lower |

| Machinability | All Directions | Less smooth finish, prone to chipping |

Need high-performance graphite for your lab or industrial application? KINTEK specializes in providing top-quality lab equipment and consumables, including extruded and isostatic graphite tailored to your specific needs. Whether you require cost-effective heating elements or complex 3D components, our experts will help you select the right material for optimal performance and durability. Contact us today to discuss your project and discover how KINTEK can enhance your laboratory efficiency!

Visual Guide

Related Products

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- How does catalytic pyrolysis work? Unlock Higher Yields of Valuable Fuels and Chemicals

- What are the safety concerns of biomass energy? Health and Environmental Risks Explained

- Why inert gas is used in sputtering? Ensure Pure, Contamination-Free Thin Film Deposition

- How thick should coating be? Achieve the Perfect Balance for Performance and Cost

- What is flash sintering? Achieve Rapid, Energy-Efficient Ceramic Densification

- What is the difference between batch type furnace and continuous type furnace? Choose the Right Tool for Your Production

- How does a constant temperature heating and stirring device ensure the quality of silver (Ag) nanosphere seed synthesis?

- What is the cost of biomass production? Unpacking the True 'Delivered Cost' to Your Facility