At its core, hydraulic press forging is a metal forming process that uses a hydraulic cylinder to generate a slow, controlled, and immense compressive force. Unlike a hammer that strikes the metal, a hydraulic press squeezes a workpiece, typically held within a die, forcing the material to flow and conform to the shape of the die cavity.

The defining characteristic of hydraulic press forging is not just the immense force it generates, but its ability to apply that force with sustained pressure and precise control throughout the entire stroke. This makes it fundamentally different from the rapid impact of mechanical hammers or presses.

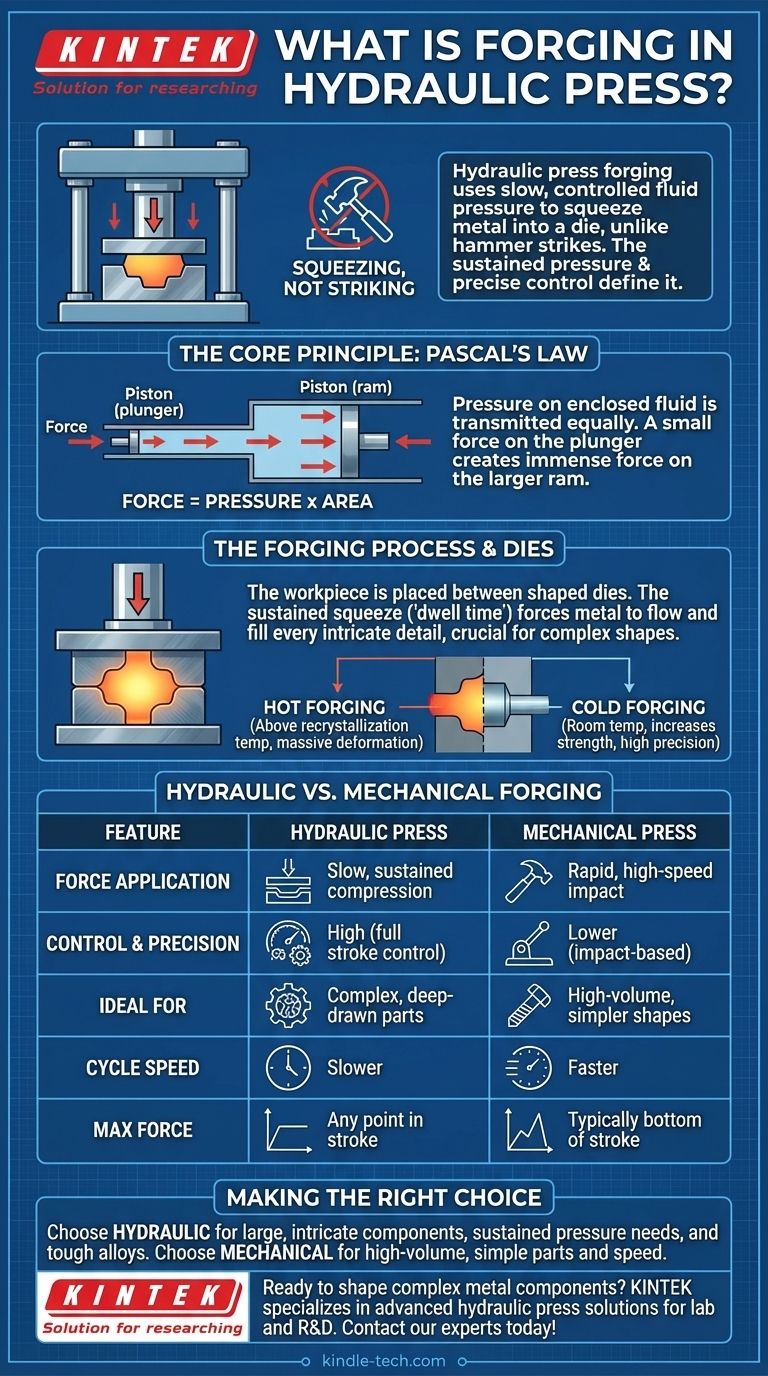

The Core Principle: How a Hydraulic Press Generates Force

To understand hydraulic forging, you must first understand the machine that powers it. The hydraulic press is a marvel of fluid mechanics, turning a small input into a massive output.

Pascal's Law: The Engine of Force Multiplication

The entire operation hinges on Pascal's Law. This principle states that pressure exerted on an enclosed fluid is transmitted equally in all directions.

A hydraulic press uses a small piston (the plunger) to apply force to a hydraulic fluid, like oil. This creates pressure, which is then transmitted to a much larger piston (the ram). Because the pressure is constant and Force = Pressure × Area, the larger surface area of the ram multiplies the initial force significantly.

The Key Components in Action

A typical system involves a hydraulic pump that moves the oil from a reservoir into the cylinder, applying pressure against the ram. As pressure builds, the ram extends with a steady, non-accelerating force.

When the operation is complete, the pressure is released, and the ram retracts, ready for the next cycle. This process is governed by advanced PLC (Programmable Logic Controller) and hydro-electronic systems for precision.

The Role of the Hydraulic Accumulator

For efficiency, many large presses use a hydraulic accumulator. This device acts like a battery, storing high-pressure hydraulic fluid while the press is idle.

When the press needs to actuate, the accumulator releases this stored energy, providing a rapid supply of high-pressure fluid without requiring an oversized pump to run continuously.

Applying Force: The Forging Process Explained

With the force generated, the actual work of shaping metal can begin. The method is more akin to kneading dough than striking an anvil.

Squeezing, Not Striking

The critical difference in hydraulic forging is the application of force. A mechanical hammer delivers energy through a high-speed impact. A hydraulic press delivers energy through slow, controlled compression.

This sustained pressure, or "dwell time" at the bottom of the stroke, is crucial. It gives the metal time to flow and fill every intricate detail of the die, which is essential for complex shapes.

The Importance of Dies

The workpiece is placed between two halves of a die, which are shaped metal blocks that contain the negative impression of the desired final part.

As the hydraulic ram presses down, it closes the die, squeezing the hot or cold workpiece. The immense pressure forces the material to flow and take on the precise shape of the die cavity.

Cold vs. Hot Forging

Hydraulic presses are used for both cold and hot forging. Hot forging is performed above the metal's recrystallization temperature, making it easier to shape and allowing for massive deformation.

Cold forging, mentioned in the press specifications, is done at or near room temperature. This process increases the strength of the metal through work hardening but requires even greater force and is typically used for smaller, simpler parts with high precision.

Understanding the Trade-offs: Hydraulic vs. Mechanical Forging

Choosing a hydraulic press for forging is a deliberate engineering decision with clear benefits and limitations compared to its mechanical counterparts.

Advantage: Unmatched Force and Control

Hydraulic presses are capable of generating enormous tonnage, often far exceeding mechanical presses. Crucially, this maximum force is available at any point during the ram's stroke, not just at the very bottom. Speed and pressure can be precisely controlled throughout the entire process.

Advantage: Deep and Complex Shapes

The slow, sustained squeeze is ideal for extruding metal and forcing it into deep, complex die cavities. This makes hydraulic forging the preferred method for producing large and intricate components for aerospace, automotive, and energy industries.

Limitation: Slower Cycle Times

The primary trade-off is speed. The process of building and releasing hydraulic pressure is inherently slower than the rapid, cyclical action of a mechanical press. This results in lower production rates, making it less suitable for high-volume, small-part manufacturing.

Limitation: Higher Cost and Complexity

Hydraulic systems are complex, involving pumps, valves, fluids, seals, and sophisticated controls. This can lead to a higher initial investment and more demanding maintenance requirements compared to simpler mechanical systems.

Making the Right Choice for Your Application

Ultimately, the choice between hydraulic and other forging methods depends entirely on the part's geometry, the material, and production volume requirements.

- If your primary focus is large, intricate components: Hydraulic forging is the superior choice due to its sustained pressure and ability to fill complex dies.

- If your primary focus is high-volume production of smaller, simpler parts: A mechanical press often provides the speed needed for better unit economics.

- If your primary focus is achieving maximum material deformation: The controlled force and dwell time of a hydraulic press are essential for forming tough alloys and large billets.

Understanding the principle of controlled pressure versus rapid impact empowers you to select the right tool for your specific engineering challenge.

Summary Table:

| Feature | Hydraulic Press Forging | Mechanical/Hammer Forging |

|---|---|---|

| Force Application | Slow, sustained compression | Rapid, high-speed impact |

| Control & Precision | High (full stroke control) | Lower (impact-based) |

| Ideal For | Complex, deep-drawn parts | High-volume, simpler shapes |

| Cycle Speed | Slower | Faster |

| Max Force Availability | Any point in stroke | Typically bottom of stroke |

Ready to shape your most complex metal components with precision? At KINTEK, we specialize in advanced lab equipment and consumables, including hydraulic press solutions tailored for demanding laboratory and R&D applications. Whether you're in aerospace, automotive, or materials science, our expertise ensures you get the controlled force and durability needed for superior results. Contact our experts today to discuss how a KINTEK hydraulic press can enhance your metal forming capabilities!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury