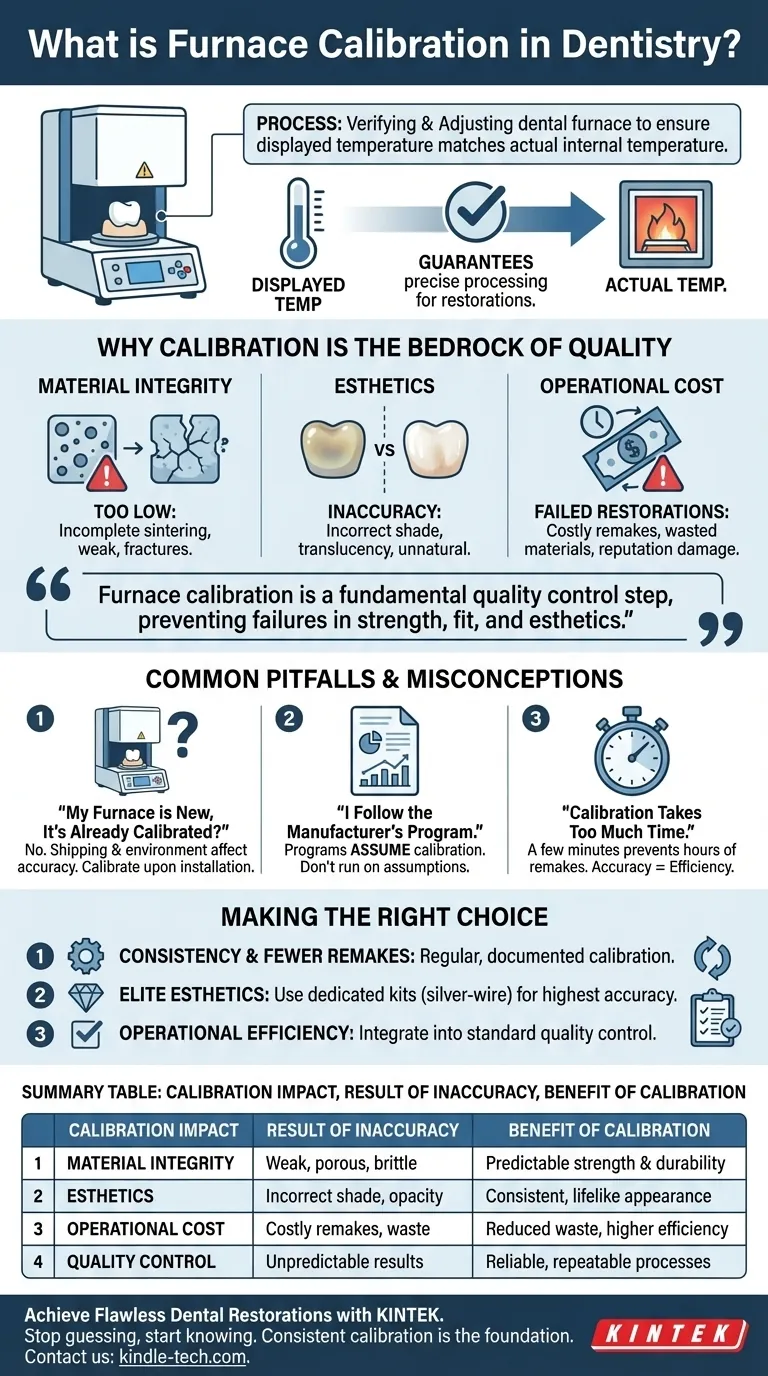

In professional dentistry, furnace calibration is the process of verifying and adjusting a dental furnace to ensure the temperature it displays matches the actual temperature inside its firing chamber. This procedure corrects any drift or inaccuracy in the furnace's thermocouple and controller, guaranteeing that dental restorations are processed at the precise temperatures required by the material manufacturer.

Furnace calibration is not just routine maintenance; it is a fundamental quality control step. It bridges the critical gap between a furnace's digital display and the physical reality inside, directly preventing failures in the strength, fit, and esthetics of dental restorations.

Why Calibration is the Bedrock of Quality Restorations

A dental furnace is a precision instrument. The success of materials like porcelain, lithium disilicate, and zirconia depends entirely on them being subjected to a specific and highly accurate heat cycle. Without calibration, you are operating on an assumption, not a fact.

The Impact on Material Integrity

When a furnace's temperature is inaccurate, it directly compromises the physical properties of the restoration.

A temperature that is too low results in incomplete sintering or glazing. This leaves the material porous and weak, making it highly susceptible to fractures in the patient's mouth.

A temperature that is too high can "over-fire" the material. For porcelain, this can cause slumping, loss of surface texture, and a glassy, unnatural appearance. For zirconia, it can lead to grain growth that makes the material more brittle.

The Consequence for Esthetics

The final shade, translucency, and vitality of a crown or veneer are directly linked to the firing temperature.

Even a deviation of just 5-10 degrees Celsius can have a noticeable effect. It can make a restoration appear too opaque, too grey, or cause the color to be incorrect, failing to match the patient's existing teeth. This is especially critical for high-value anterior restorations where esthetics are paramount.

The Inevitable Cost of Inaccuracy

An uncalibrated furnace leads directly to failed restorations. This results in costly remakes that waste valuable technician time, expensive materials, and shipping costs. More importantly, it can damage a dental lab's reputation with its clients.

Common Pitfalls and Misconceptions

Trust in the process requires understanding the common points of failure. Ignoring calibration is one of the most frequent, yet avoidable, sources of inconsistent results in a dental lab.

"My Furnace is New, It's Already Calibrated"

While a furnace is calibrated at the factory, its accuracy can be affected by shipping, handling, and environmental factors at your location, such as ambient temperature and voltage fluctuations. Calibration should be performed upon installation.

"I Follow the Material Manufacturer's Program"

The pre-set firing programs provided by material manufacturers assume your furnace is perfectly calibrated. Running a "Zirconia" cycle on an uncalibrated furnace that is running 15°C too hot is not following the correct protocol.

"Calibration Takes Too Much Time"

The few minutes it takes to perform a calibration test pales in comparison to the hours lost on a single remake. It is a high-leverage activity that prevents far greater time and resource loss down the line. Accuracy is the foundation of efficiency.

Making the Right Choice for Your Goal

Implementing a calibration protocol is not a suggestion; it is a professional requirement for producing safe and predictable results.

- If your primary focus is consistency and minimizing remakes: Perform and document furnace calibration on a regular schedule, such as monthly, and after any major event like replacing a heating element or muffle.

- If your primary focus is achieving elite-level esthetics: Calibrate your furnace using a silver-wire or other dedicated calibration kit to ensure the highest degree of accuracy for sensitive porcelain and staining systems.

- If your primary focus is operational efficiency: Integrate calibration into your lab's standard quality control system, treating it as a non-negotiable step that protects your bottom line.

Ultimately, consistent calibration transforms your furnace from a variable into a constant, giving you full control over the final outcome.

Summary Table:

| Calibration Impact | Result of Inaccuracy | Benefit of Calibration |

|---|---|---|

| Material Integrity | Weak, porous, or brittle restorations | Predictable strength and durability |

| Esthetics | Incorrect shade, opacity, or texture | Consistent, lifelike appearance |

| Operational Cost | Costly remakes and wasted materials | Reduced waste and higher efficiency |

| Quality Control | Unpredictable results and reputation damage | Reliable, repeatable processes |

Achieve Flawless Dental Restorations with KINTEK

Stop guessing and start knowing. Consistent furnace calibration is the foundation of predictable, high-quality dental lab work. KINTEK specializes in the precise lab equipment and consumables that dental technicians rely on for exceptional results.

Ensure every crown, veneer, and bridge meets the highest standards of strength and esthetics. Let our expertise help you eliminate costly remakes and build a reputation for reliability.

Contact KINTEK today to discuss your lab's needs and discover how our solutions can enhance your quality control process.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is a recommended maintenance practice for modern ceramic furnaces? Prioritize Firmware Updates for Peak Performance

- Which is cheaper porcelain or ceramic crown? A Practical Guide to Dental Crown Costs & Materials

- What can all-ceramic restorations be used for? Complete Guide to Modern Dental Solutions

- What are the 3 types of materials used for all-ceramic restorations? Master the Aesthetics vs. Strength Trade-Off

- What is the average lifespan of a dental restoration? Maximize Your Investment with the Right Material

- What is a dental ceramic furnace? A Precision Oven for High-Strength, Aesthetic Restorations

- How are Dental Press Furnaces used with modern dental technologies? Optimize Your CAD/CAM Digital Workflow

- What is the sintering temperature of dental zirconia? Achieve Maximum Strength & Aesthetics