At its core, high-temperature chemical vapor deposition (CVD) is a process used to grow a solid, high-performance thin film onto a surface from chemical ingredients in a gaseous state. A substrate, or the part to be coated, is heated to a high temperature inside a reaction chamber and exposed to volatile precursor gases. The intense heat acts as the catalyst, causing a chemical reaction that deposits a new, solid material directly onto the substrate's surface, atom by atom.

The critical concept to understand is that CVD is not simply a coating process like painting; it is a synthesis process. You are chemically growing a new, engineered layer with superior purity and adhesion directly onto an object's surface using heat to drive the transformation from gas to solid.

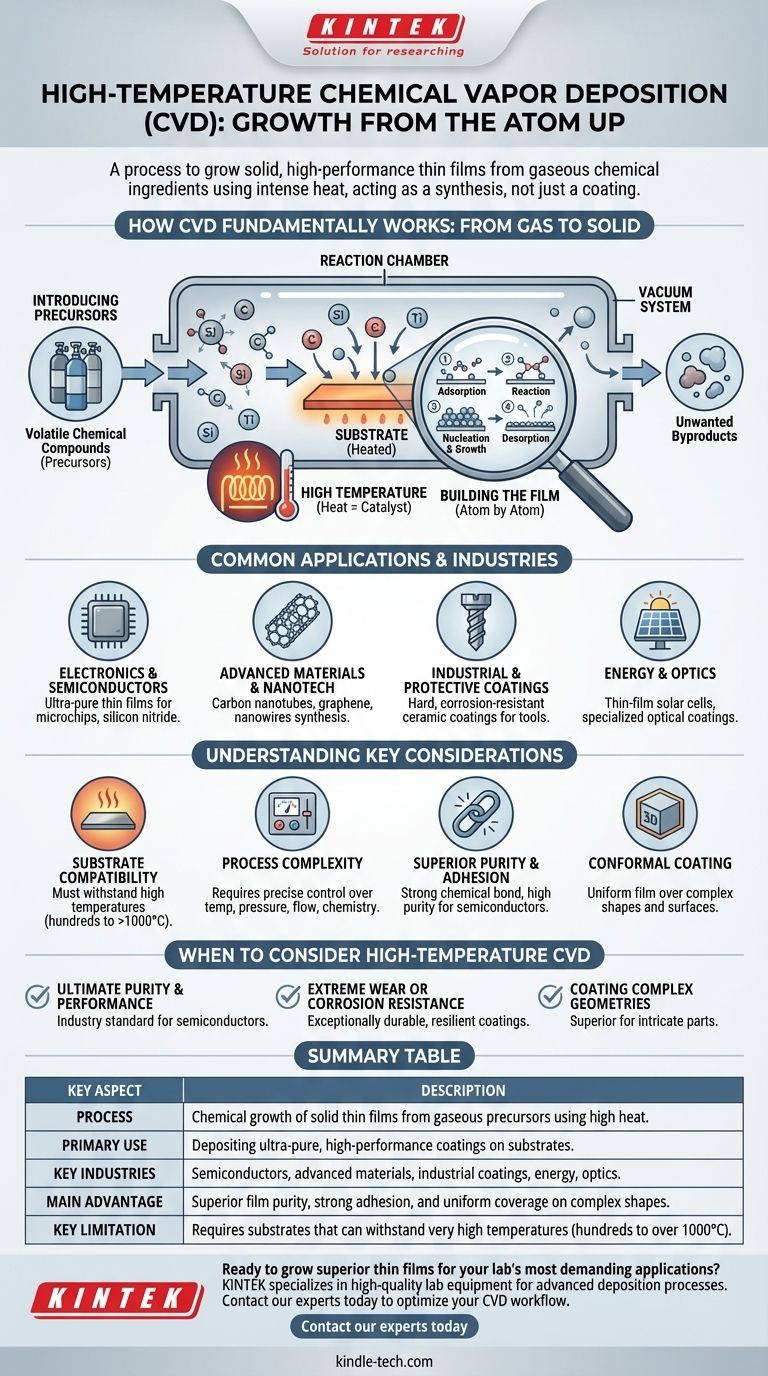

How CVD Fundamentally Works: From Gas to Solid

The CVD process might seem complex, but it can be broken down into a series of logical, controlled steps. It all happens within a highly controlled environment to ensure the purity and quality of the final film.

The Controlled Environment

The entire process takes place within a sealed reaction chamber, which is typically held under a vacuum. This vacuum environment removes contaminants and allows for precise control over the gases and pressures involved.

Introducing the Precursors

Volatile chemical compounds, known as precursors, are injected into the chamber in gaseous form. These gases contain the specific atoms (like silicon, carbon, or titanium) that will eventually form the solid film.

The Role of High Temperature

The substrate is heated to a specific, often very high, temperature. This heat provides the necessary energy for thermal decomposition, breaking down the precursor gases and initiating the desired chemical reactions right at the substrate's surface.

Building the Film, Atom by Atom

Once the precursor gases react, a highly structured sequence occurs at the molecular level:

- Adsorption: The reactive gas molecules stick to the hot substrate surface.

- Reaction: Surface-catalyzed reactions create the desired solid material and gaseous byproducts.

- Nucleation & Growth: The solid atoms diffuse across the surface to form stable clusters (nuclei), which then grow into a continuous, thin film.

- Desorption: Unwanted gaseous byproducts are released from the surface and transported away by the vacuum system.

Common Applications and Industries

Because CVD can produce extremely pure, dense, and durable films, it has become a foundational technology in numerous high-tech fields.

Electronics and Semiconductors

This is one of the most common uses for CVD. It is essential for depositing the ultra-pure thin films of silicon, silicon nitride, and other materials that form the basis of microchips and integrated circuits.

Advanced Materials and Nanotechnology

CVD is a leading method for growing highly structured materials with unique properties. This includes the synthesis of carbon nanotubes, graphene, and various nanowires for next-generation electronics and composites.

Industrial and Protective Coatings

The process is used to apply exceptionally hard and corrosion-resistant ceramic coatings, like titanium nitride, onto cutting tools and industrial components. This dramatically increases their lifespan and performance.

Energy and Optics

In the energy sector, CVD is used to deposit the critical photovoltaic materials that make up thin-film solar cells. It is also used to apply specialized coatings to glass and other optical components.

Understanding the Key Considerations

While powerful, CVD is a highly technical process with specific requirements and trade-offs that determine its suitability for a given application.

Substrate Compatibility

The "high-temperature" aspect is a critical limitation. The base material, or substrate, must be able to withstand the required reaction temperature (which can be several hundred to over a thousand degrees Celsius) without melting, warping, or degrading.

Process Complexity

Achieving a high-quality, uniform film requires precise control over numerous variables, including temperature, pressure, gas flow rates, and chemistry. This demands sophisticated equipment and a high level of technical expertise.

Superior Purity and Adhesion

Because the film is grown through a chemical reaction, it forms a strong, direct chemical bond with the substrate. The vacuum environment also ensures an exceptionally high level of purity, which is critical for semiconductor applications.

Conformal Coating Capability

A major advantage of CVD is its ability to deposit a perfectly uniform film over complex shapes and three-dimensional surfaces. Since the precursor is a gas, it can reach every exposed area of the part, ensuring complete and even coverage.

When to Consider High-Temperature CVD

Choosing a manufacturing process depends entirely on your end goal. High-temperature CVD excels in applications where material performance is the primary driver.

- If your primary focus is ultimate purity and electrical performance: CVD is the industry standard for creating the foundational layers in semiconductors and advanced electronics.

- If your primary focus is extreme wear or corrosion resistance: The strong chemical bonds formed by CVD create exceptionally durable and resilient coatings for demanding industrial environments.

- If your primary focus is coating complex geometries with a uniform film: The gaseous nature of the CVD process makes it superior to line-of-sight methods for coating intricate parts.

Ultimately, high-temperature CVD is the definitive technology for building advanced materials from the atom up, creating layers that are not just applied to a surface, but are an integral part of it.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Chemical growth of solid thin films from gaseous precursors using high heat. |

| Primary Use | Depositing ultra-pure, high-performance coatings on substrates. |

| Key Industries | Semiconductors, advanced materials, industrial coatings, energy, optics. |

| Main Advantage | Superior film purity, strong adhesion, and uniform coverage on complex shapes. |

| Key Limitation | Requires substrates that can withstand very high temperatures (hundreds to over 1000°C). |

Ready to grow superior thin films for your lab's most demanding applications? High-temperature CVD requires precise control and reliable equipment to achieve the material purity and performance your research demands. At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to advanced deposition processes. Whether you're working in semiconductor fabrication, developing new nanomaterials, or need durable protective coatings, our expertise can help you optimize your CVD workflow. Contact our experts today to discuss how our solutions can enhance your lab's capabilities and drive your innovations forward.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method