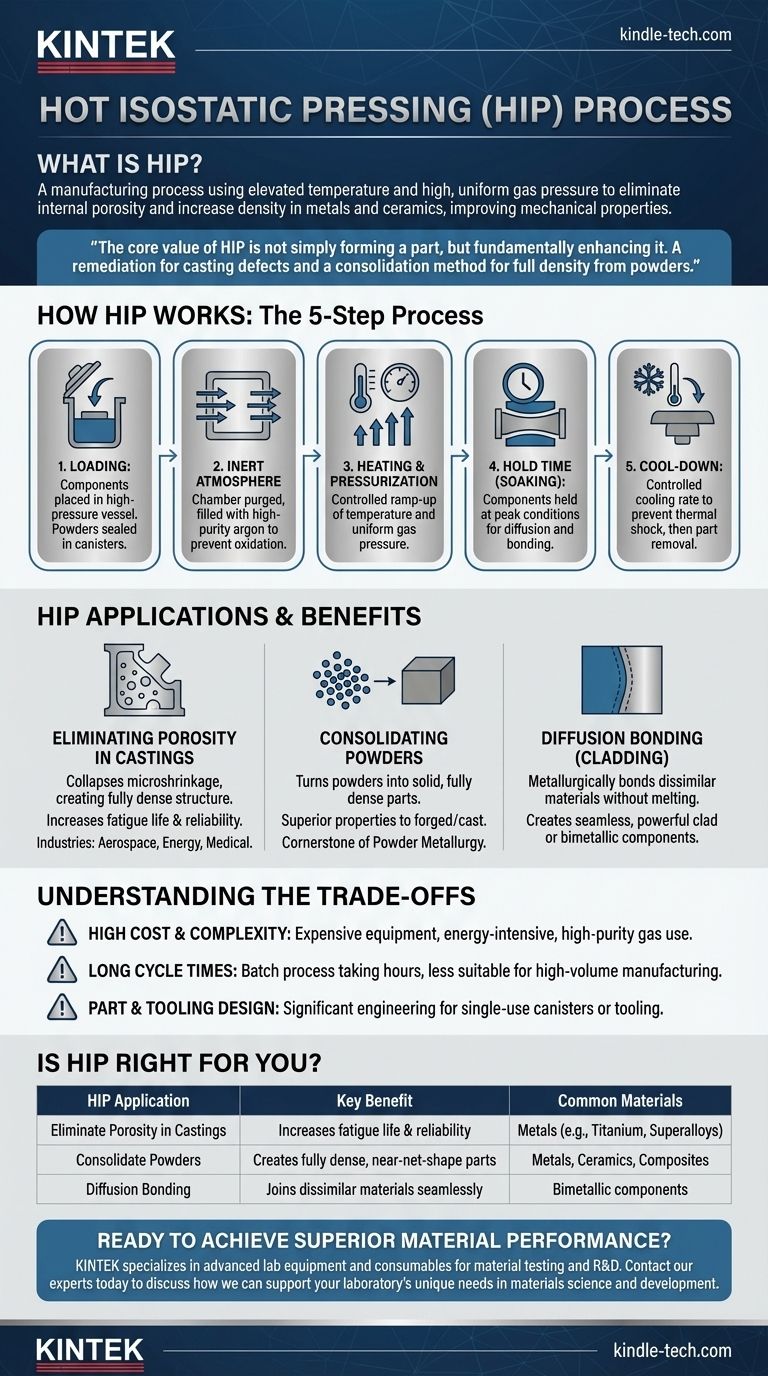

In short, Hot Isostatic Pressing (HIP) is a manufacturing process that subjects components to both elevated temperature and high, uniform gas pressure. This combination is used to eliminate internal porosity and increase the density of materials like metals and ceramics, dramatically improving their mechanical properties and reliability.

The core value of HIP is not simply forming a part, but fundamentally enhancing it. It is a remediation process that closes internal defects in castings and a consolidation method that creates fully dense components from powders, achieving a level of material integrity that is often impossible with other methods.

How Does Hot Isostatic Pressing Work?

HIP combines three critical elements—heat, pressure, and an inert atmosphere—in a tightly controlled environment to alter a material's microstructure for the better.

The Core Principle: Uniform Pressure

The "isostatic" part of the name is key. Unlike forging or stamping, which apply pressure from a specific direction, HIP applies uniform (isostatic) pressure from all sides simultaneously.

This hydrostatic pressure is transmitted by a gas, ensuring that the component is squeezed evenly. This pressure acts on any internal voids or pores, causing them to collapse and weld shut on a microscopic level.

The Step-by-Step Process

A typical HIP cycle is managed by computer-controlled equipment and follows a precise sequence.

-

Loading: Components are placed inside a high-pressure vessel. For consolidating powders, the powder is first sealed in a flexible mold or metallic canister that acts as a pressure-tight barrier.

-

Inert Atmosphere: The chamber is purged of air and filled with a high-purity inert gas, most commonly argon. This prevents the material from oxidizing or reacting at high temperatures.

-

Heating and Pressurization: The temperature and pressure are ramped up in a controlled manner. The specific temperature, pressure, and duration are tailored to the material being processed and the desired outcome.

-

Hold Time (Soaking): The components are held at the peak temperature and pressure for a set period. During this phase, material diffusion and plastic deformation occur, closing internal pores and, in the case of powders, bonding the particles together.

-

Cool-Down: The vessel is cooled at a controlled rate to prevent thermal shock to the components. Once at a safe temperature and pressure, the parts are removed.

What Problems Does HIP Solve?

HIP is not a primary forming method but a specialized process used for three main applications. It is chosen when the performance and reliability requirements of a component justify the investment.

Eliminating Porosity in Castings

Even the most advanced casting processes can leave behind tiny internal voids called microshrinkage. While invisible on the surface, these defects act as stress concentrators and can lead to premature failure.

HIP collapses these voids, creating a fully dense and homogenous microstructure. This is critical for high-performance cast parts in industries like aerospace, energy, and medical implants.

Consolidating Powders

HIP can turn metal, ceramic, or composite powders into a solid, fully dense part. The powder is placed in a sealed canister that is shaped like the final component.

Under heat and pressure, the powder particles deform and diffuse into one another, creating a solid part with properties that can be superior to those of forged or cast equivalents. This is a cornerstone of modern powder metallurgy.

Diffusion Bonding (Cladding)

The process can be used to metallurgically bond two or more different materials together without melting or using filler metals.

By placing dissimilar materials in direct contact within the HIP vessel, the high heat and pressure promote atomic diffusion across the interface. This creates a powerful, seamless bond, allowing for the creation of clad or bimetallic components with unique property combinations.

Understanding the Trade-offs

While powerful, HIP is a specialized process with important considerations. It is not a universal solution for all manufacturing challenges.

High Cost and Complexity

HIP equipment is expensive to acquire and operate. The process is energy-intensive and consumes large amounts of costly high-purity argon gas, making it a significant investment.

Long Cycle Times

A single HIP cycle—including loading, heating, soaking, and cooling—can last for many hours. This makes it a batch process that is less suitable for high-volume, low-cost manufacturing compared to continuous methods.

Part and Tooling Design

For powder consolidation or diffusion bonding, significant engineering is required to design the canisters or tooling. This tooling is often single-use, adding to the overall cost and complexity of the process.

Is Hot Isostatic Pressing Right for Your Application?

Choosing HIP depends entirely on your final goal for the component.

- If your primary focus is upgrading critical cast components: Use HIP to eliminate internal porosity, dramatically increasing the fatigue life and reliability of parts used in demanding aerospace, energy, or medical applications.

- If your primary focus is creating complex parts from advanced materials: Use HIP to consolidate powders into a fully dense, near-net-shape component, bypassing the limitations and waste of traditional machining from a solid block.

- If your primary focus is joining dissimilar materials for extreme performance: Use HIP for diffusion bonding to create seamless, metallurgically bonded parts that outperform welded or brazed assemblies in corrosive or high-temperature environments.

By understanding its principles, you can leverage HIP not just as a manufacturing step, but as a strategic tool to achieve unprecedented material performance.

Summary Table:

| HIP Application | Key Benefit | Common Materials |

|---|---|---|

| Eliminate Porosity in Castings | Increases fatigue life & reliability | Metals (e.g., Titanium, Superalloys) |

| Consolidate Powders | Creates fully dense, near-net-shape parts | Metals, Ceramics, Composites |

| Diffusion Bonding | Joins dissimilar materials seamlessly | Bimetallic components |

Ready to achieve superior material performance for your critical components? KINTEK specializes in advanced lab equipment and consumables, including solutions for material testing and R&D in powder metallurgy and advanced manufacturing. Our expertise can help you optimize processes like Hot Isostatic Pressing to enhance the reliability and durability of your products. Contact our experts today to discuss how we can support your laboratory's unique needs in materials science and development.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Double Plate Heating Press Mold for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Anti-Cracking Press Mold for Lab Use

People Also Ask

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What is the historical background of the Hot Isostatic Pressing (HIP) process? From Nuclear Roots to Industry Standard

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance