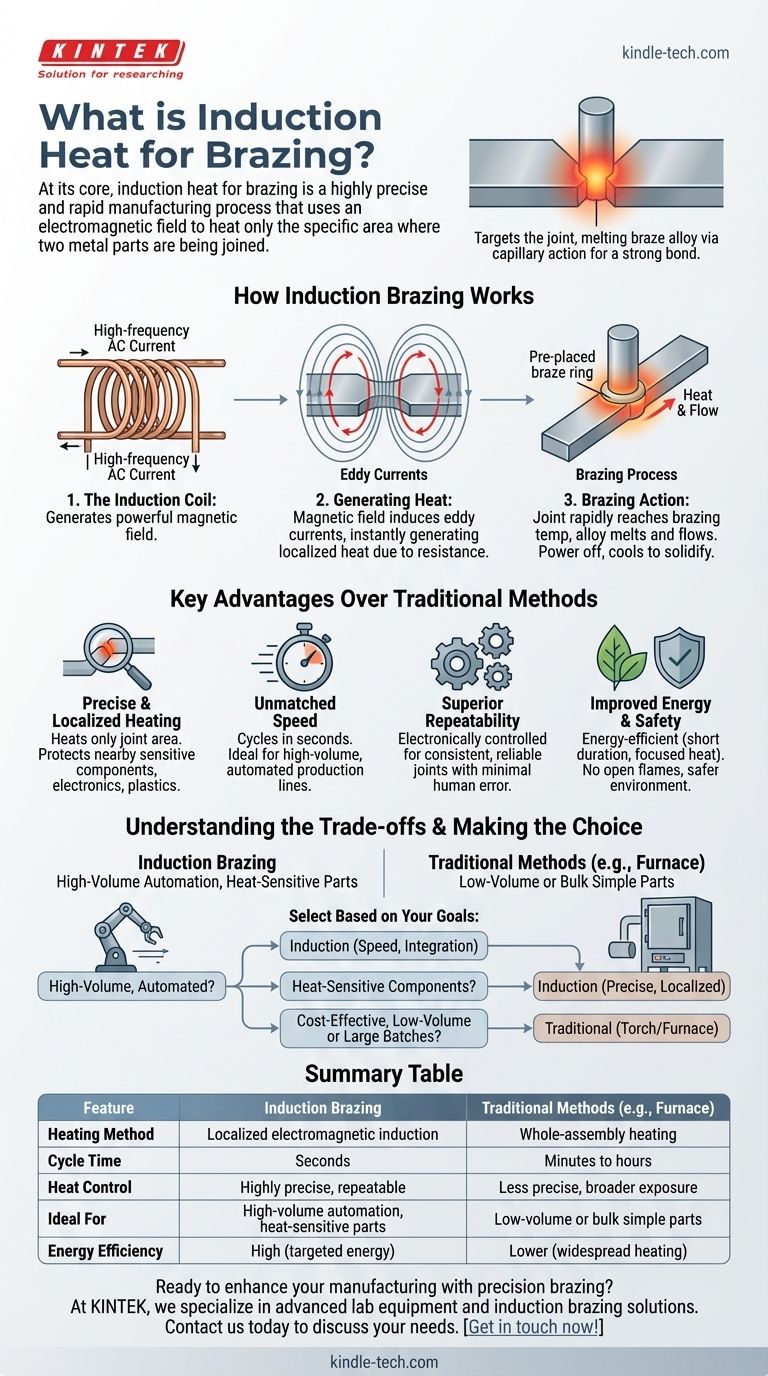

At its core, induction heat for brazing is a highly precise and rapid manufacturing process that uses an electromagnetic field to heat only the specific area where two metal parts are being joined. Unlike methods that heat the entire assembly, induction targets the joint, causing a filler metal (the braze alloy) to melt and flow via capillary action, creating an exceptionally strong bond upon cooling.

The fundamental advantage of induction brazing is not just how it heats, but what it doesn't heat. By localizing energy directly at the joint, it offers unparalleled speed, control, and repeatability, protecting sensitive components from unwanted heat exposure.

How Induction Brazing Works

Induction heating is a non-contact process. It relies on the principles of electromagnetism to generate heat directly within the parts being joined, rather than applying an external heat source like a flame or furnace element.

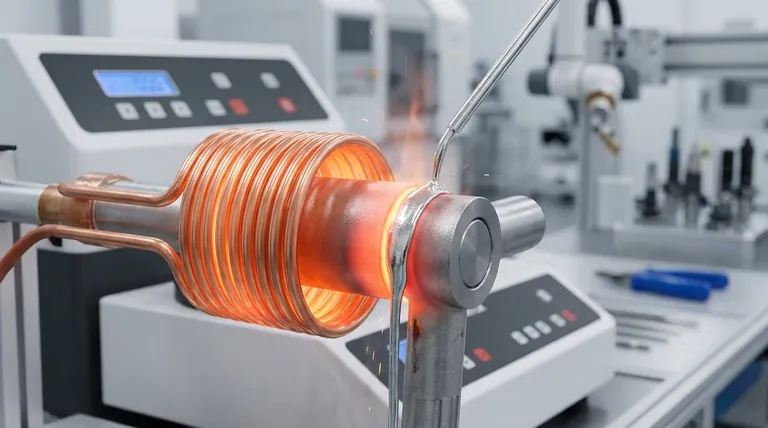

The Role of the Induction Coil

The process starts with a custom-designed induction coil, typically made of copper tubing. A high-frequency alternating current (AC) is passed through this coil.

This current generates a powerful and rapidly alternating magnetic field in the space within and around the coil.

Generating Heat with Eddy Currents

When the metal assembly to be brazed is placed within this magnetic field, the field induces circulating electrical currents within the metal itself. These are known as eddy currents.

The inherent electrical resistance of the metal parts opposes the flow of these eddy currents, which instantly generates intense, localized heat. This is the same principle that allows a magnetic stove top to heat a pan without the surface itself getting hot.

The Brazing Process in Action

The operational steps are simple and fast. The components are assembled with the braze alloy pre-placed at the joint, often in the form of a ring or paste.

The assembly is placed inside the induction coil, power is applied for a few seconds, and the joint area rapidly reaches the brazing temperature. The alloy melts, flows into the joint, the power is shut off, and the part cools, solidifying the joint.

Key Advantages Over Traditional Methods

When compared to a method like furnace brazing, where the entire assembly is baked for an extended period, the unique benefits of induction become clear.

Precise and Localized Heating

This is the most significant advantage. Induction heats only the metal near the joint. This is critical for applications involving electromechanical components or assemblies where nearby plastic, electronics, or heat-treated zones would be damaged by the widespread heat of a furnace.

Unmatched Speed and Throughput

Induction heating cycles are measured in seconds, not minutes or hours. This makes it ideal for integrating directly into high-volume, automated production lines, significantly increasing throughput compared to batch-based furnace processes.

Superior Repeatability and Quality Control

The induction process is electronically controlled. The power level, frequency, and heating duration can be set precisely and repeated thousands of time without deviation. This results in highly consistent, reliable joints with minimal human error.

Improved Energy Efficiency and Safety

Since energy is only applied for a short duration and is focused on a small area, induction brazing is far more energy-efficient. It also creates a safer work environment with no open flames and significantly less ambient heat.

Understanding the Trade-offs

While powerful, induction brazing is not a universal solution. Its effectiveness is tied to specific physical and economic factors.

Initial Equipment Investment

The initial cost for an induction power supply and custom-fabricated coils can be substantial. This method is best justified for high-volume production where the return on investment is clear.

Dependence on Part Geometry

The shape of the parts dictates the design of the induction coil. For a strong joint, the heating must be uniform. Complex or irregular geometries can make it difficult to design a coil that heats the joint area evenly.

Not Ideal for Bulk Processing

Furnace brazing excels at processing thousands of small, non-sensitive parts simultaneously in a single batch. Induction is a serial process, handling one assembly at a time, which is less efficient for this type of mass production.

Making the Right Choice for Your Application

Selecting the right brazing method depends entirely on your specific goals for quality, volume, and the nature of your components.

- If your primary focus is high-volume, automated production: Induction is the superior choice for its speed and seamless integration into production lines.

- If your primary focus is joining assemblies with heat-sensitive components: Induction's precise, localized heating is often the only viable option to prevent damage.

- If your primary focus is cost-effective, low-volume production: Traditional torch or furnace brazing may be more economical without the need for custom tooling.

- If your primary focus is processing large batches of simple parts: Furnace brazing offers an efficiency of scale that induction cannot match.

By understanding its principle of targeted energy, you can leverage induction brazing to achieve unparalleled speed, precision, and quality in your manufacturing process.

Summary Table:

| Feature | Induction Brazing | Traditional Methods (e.g., Furnace) |

|---|---|---|

| Heating Method | Localized electromagnetic induction | Whole-assembly heating |

| Cycle Time | Seconds | Minutes to hours |

| Heat Control | Highly precise, repeatable | Less precise, broader heat exposure |

| Ideal For | High-volume automation, heat-sensitive parts | Low-volume or bulk simple parts |

| Energy Efficiency | High (targeted energy) | Lower (widespread heating) |

Ready to enhance your manufacturing with precision brazing?

At KINTEK, we specialize in advanced lab equipment and consumables, including induction brazing solutions tailored to your laboratory and production needs. Our expertise ensures you achieve stronger bonds, faster throughput, and superior protection for sensitive components.

Contact us today to discuss how our induction brazing systems can optimize your process. Get in touch now!

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Automatic Laboratory Heat Press Machine

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

People Also Ask

- What is the speed of a sieving machine? Optimize Vibration for Maximum Efficiency and Accuracy

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- What does a vibrating sieve do? Automate Particle Size Analysis for Accurate Results