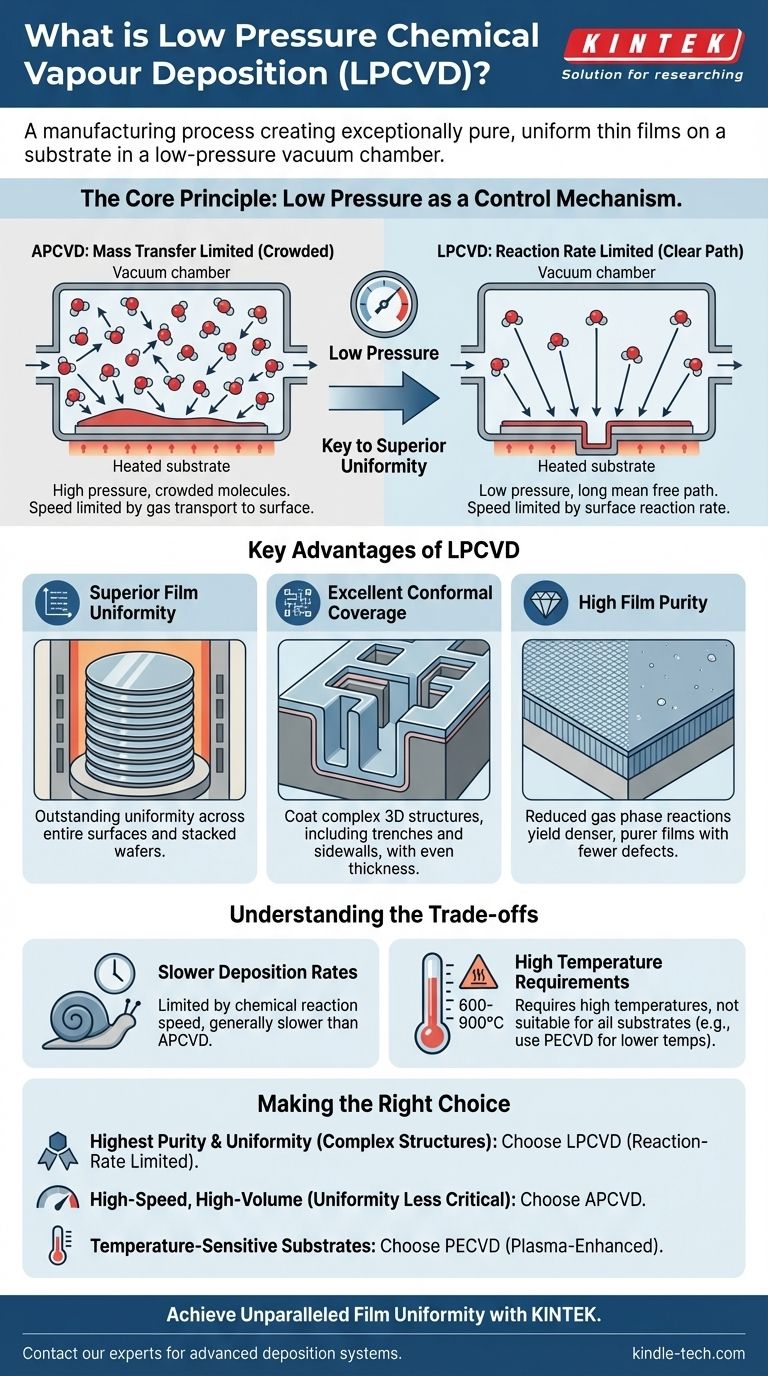

In short, Low-Pressure Chemical Vapor Deposition (LPCVD) is a manufacturing process used to create exceptionally pure and uniform thin solid films on a substrate. It operates within a vacuum chamber at very low pressures, where precursor gases are introduced and react on a heated surface to form the desired material layer. This low-pressure environment is the key to its precision.

The critical insight is that LPCVD's low pressure isn't just an operating condition; it's a control mechanism. By reducing pressure, the process becomes limited by the speed of the chemical reaction on the surface, not by how fast gas can travel, which is the secret to achieving superior film quality and uniformity.

The Core Principle: How Low Pressure Changes Everything

To understand LPCVD, we must first distinguish it from its atmospheric pressure counterpart (APCVD). The difference in pressure fundamentally changes the physics of the deposition.

The Role of Low Pressure

In an LPCVD system, the pressure is significantly reduced. This dramatically increases the mean free path—the average distance a gas molecule travels before colliding with another.

With fewer collisions in the gas phase, the precursor molecules are much more likely to travel unimpeded and reach every part of the substrate's surface, including complex trenches and cavities.

Reaction Rate vs. Mass Transfer

This leads to the two fundamental modes of CVD operation.

-

Mass Transfer Limited (Typical for APCVD): At atmospheric pressure, the chamber is crowded with gas molecules. The process speed is limited by how quickly the precursor gases can physically get to the substrate. This can lead to uneven deposition, with thicker films where the gas inlet is and thinner films elsewhere.

-

Reaction Rate Limited (The LPCVD Advantage): At low pressure, the gas molecules have a clear path to the surface. The bottleneck is no longer transportation; it is the intrinsic speed of the chemical reaction on the heated substrate. Because the temperature is uniform across the substrate, the reaction rate is also uniform, resulting in a film of consistent thickness everywhere.

Why Choose LPCVD? Key Advantages

The reaction-rate-limited nature of LPCVD provides distinct advantages that make it essential for high-performance applications, particularly in semiconductor manufacturing.

Superior Film Uniformity

Because deposition is not dependent on gas flow dynamics, LPCVD provides outstanding film uniformity across the entire surface of a wafer.

This also allows for high-throughput processing where wafers can be stacked vertically in a furnace, as the gas can easily penetrate the entire stack and coat each wafer evenly.

Excellent Conformal Coverage

LPCVD excels at creating conformal films, meaning the film's thickness is the same on horizontal surfaces, vertical sidewalls, and in deep trenches.

This is critical for fabricating complex, three-dimensional microelectronic structures where every surface must be coated perfectly.

High Film Purity

The low-pressure environment and controlled reaction on the substrate surface minimize unwanted chemical reactions in the gas phase.

This results in denser, purer films with fewer defects compared to other CVD methods.

Understanding the Trade-offs

No process is perfect. The precision of LPCVD comes with specific limitations that must be considered.

Slower Deposition Rates

Because the process is limited by the chemical reaction speed rather than a high-volume flow of gas, LPCVD is generally slower than APCVD. This can impact overall manufacturing throughput.

High Temperature Requirements

Driving the surface chemical reaction often requires high temperatures, typically in the range of 600-900°C.

These high temperatures are not suitable for all materials and can be a limiting factor when depositing films on substrates that cannot withstand the heat. For these cases, alternative methods like Plasma-Enhanced CVD (PECVD) are used, which operate at lower temperatures.

Making the Right Choice for Your Goal

Selecting a deposition technique requires aligning the process capabilities with your primary objective for the thin film.

- If your primary focus is achieving the highest possible film purity and uniformity for complex structures: LPCVD is the superior choice due to its reaction-rate-limited nature.

- If your primary focus is high-speed, high-volume deposition where perfect uniformity is less critical: Atmospheric Pressure CVD (APCVD) may be a more suitable and economical option.

- If your primary focus is depositing films on temperature-sensitive substrates: Plasma-Enhanced CVD (PECVD) is the necessary alternative, as it uses plasma energy to enable reactions at much lower temperatures.

Ultimately, understanding the fundamental physics of the deposition environment is the key to selecting the right tool for the job.

Summary Table:

| Aspect | LPCVD Characteristic |

|---|---|

| Process Environment | Vacuum chamber, low pressure (reaction-rate limited) |

| Key Advantage | Superior uniformity & conformal coverage on complex structures |

| Typical Temperature | High (600-900°C) |

| Best For | High-purity applications requiring precise, even film thickness |

| Trade-off | Slower deposition rate compared to APCVD |

Ready to achieve unparalleled film uniformity in your lab?

KINTEK specializes in precision lab equipment, including advanced deposition systems. Whether you're developing next-generation semiconductors or require high-purity thin films, our expertise can help you select the right technology for your specific needs.

Contact our experts today to discuss how our solutions can enhance your research and manufacturing processes.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is microwave plasma CVD? A Guide to High-Purity Diamond and Material Synthesis

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- What is the hot filament chemical vapour deposition of diamond? A Guide to Synthetic Diamond Coating

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication