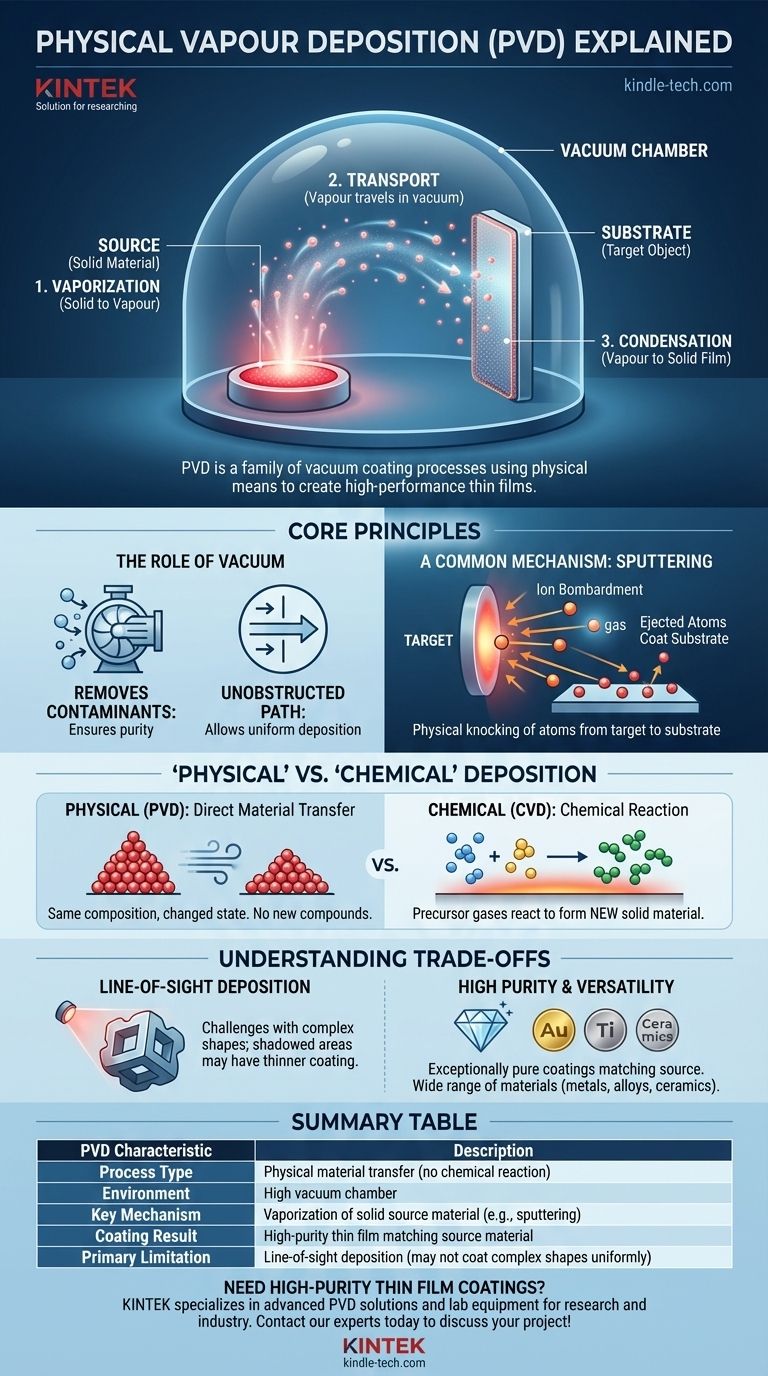

In essence, Physical Vapour Deposition (PVD) is a family of coating processes performed inside a vacuum chamber. These techniques use purely physical means—like heating or particle bombardment—to turn a solid source material into a vapor, which then travels and condenses onto a target object (the substrate) as a high-performance thin film.

The critical distinction of PVD is that it is a physical transfer process. It moves a material from a source to a surface without inducing a chemical reaction, ensuring the deposited film maintains the fundamental properties of the original material.

How PVD Actually Works

At its core, PVD is a three-step process that takes place in a highly controlled, low-pressure environment. Understanding this sequence clarifies how it achieves such precise and high-quality coatings.

The Core Principle: From Solid to Vapour to Solid

All PVD processes involve transforming a solid material into a gaseous vapor phase and then back into a solid thin film. This happens by physically energizing the source material until its atoms or molecules are liberated from its surface.

Once vaporized, these particles travel through the vacuum chamber and land on the substrate. Upon contact with the cooler substrate, the vapor condenses, solidifying and building up a thin, uniform layer.

The Role of the Vacuum

The entire process is conducted in a vacuum for two critical reasons. First, it removes air and other contaminants that could react with the vapor and compromise the purity of the final coating.

Second, the vacuum creates a clear, unobstructed path. This allows the vaporized atoms to travel from the source to the substrate in a straight line without colliding with air molecules, which would scatter them and prevent a uniform coating.

A Common Mechanism: Sputtering

One of the most common PVD methods is sputtering. This is a purely physical mechanism where a solid source material, known as the "target," is bombarded with high-energy ions (typically from an inert gas like argon).

These energetic collisions act like a microscopic sandblaster, physically knocking atoms off the surface of the target. These ejected atoms then travel through the vacuum and deposit onto the substrate, forming the desired film.

The Defining Characteristic: "Physical" vs. "Chemical"

The term "physical" in PVD is not arbitrary; it draws a sharp contrast with another major deposition family, Chemical Vapour Deposition (CVD). This distinction is fundamental to understanding its applications and limitations.

What "Physical" Really Means

In PVD, the material of the coating already exists in its final chemical form in the solid source. The process simply changes its state from solid to vapor and back to solid again. No new compounds are formed on the substrate's surface.

Think of it like moving sand from one pile to another using a gust of wind. The sand's composition does not change during its journey.

The Contrast with Chemical Vapour Deposition (CVD)

CVD, by contrast, involves introducing precursor gases into a chamber. These gases undergo a chemical reaction directly on the hot surface of the substrate, forming an entirely new solid material as the coating.

While CVD can offer excellent properties like the ability to coat complex shapes evenly ("wrap-around"), its reliance on chemical reactions makes it a fundamentally different process from the direct material transfer of PVD.

Understanding the Trade-offs

Like any technical process, PVD has inherent characteristics that make it ideal for some applications and less suitable for others. Its physical nature dictates its primary strengths and weaknesses.

Line-of-Sight Deposition

Because the vaporized material travels in a straight line from the source to the substrate, PVD is often considered a line-of-sight process. Areas of a complex object that are "shadowed" from the source may receive a thinner coating or no coating at all.

This means achieving a perfectly uniform coating on intricate 3D shapes can be challenging and may require rotating the substrate or using multiple deposition sources.

High Purity and Material Versatility

The vacuum environment and the absence of chemical reactions mean that PVD coatings can be exceptionally pure. The final film is a direct reflection of the source material.

This also means PVD can be used to deposit a vast range of materials, including metals, alloys, and certain ceramics, without altering their composition.

How to Apply This to Your Project

Understanding the core principles of PVD allows you to determine if it's the right approach for your specific material science or engineering goal.

- If your primary focus is creating a high-purity coating of a specific material: PVD is a direct and reliable method for transferring that exact material from a source onto your substrate.

- If your primary focus is to coat a complex, non-flat shape with perfect uniformity: Be aware of PVD's line-of-sight nature and consider if your part's geometry is compatible or if an alternative like CVD might be more suitable.

- If your primary focus is avoiding high temperatures: Many PVD processes can be performed at relatively low temperatures, making them suitable for coating heat-sensitive substrates.

Ultimately, Physical Vapour Deposition is a powerful tool for engineering surfaces at the atomic level, creating high-performance films for countless advanced applications.

Summary Table:

| PVD Characteristic | Description |

|---|---|

| Process Type | Physical material transfer (no chemical reaction) |

| Environment | High vacuum chamber |

| Key Mechanism | Vaporization of solid source material (e.g., sputtering) |

| Coating Result | High-purity thin film matching source material |

| Primary Limitation | Line-of-sight deposition (may not coat complex shapes uniformly) |

Need high-purity thin film coatings for your laboratory applications? KINTEK specializes in advanced PVD solutions and lab equipment, delivering precise material deposition for research and industry. Our expertise ensures your substrates receive the exact coating properties you require. Contact our experts today to discuss how our PVD systems can enhance your project's performance and reliability.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is a plasma arc furnace? Achieve Unmatched Purity and Control for Specialty Alloys

- What is a sintering machine? Transforming Powders into High-Performance Parts

- What is the function of the vacuum pressure impregnation tank in the PIP process? Achieve High-Density CMCs

- Why is a high-performance vacuum system required for alloy distillation? Boost Purity with 10–15 Pa Control

- What is the difference between a vacuum furnace and an atmosphere furnace? Choose the Right Heat Treatment for Your Materials

- What role does a high-temperature industrial furnace play in the sintering and leaching of scheelite? Optimize Extraction

- What metal Cannot be brazed? Overcoming Surface Chemistry for Strong Joints

- What is the cooling process of hardening? Master the Quenching Step for Maximum Hardness