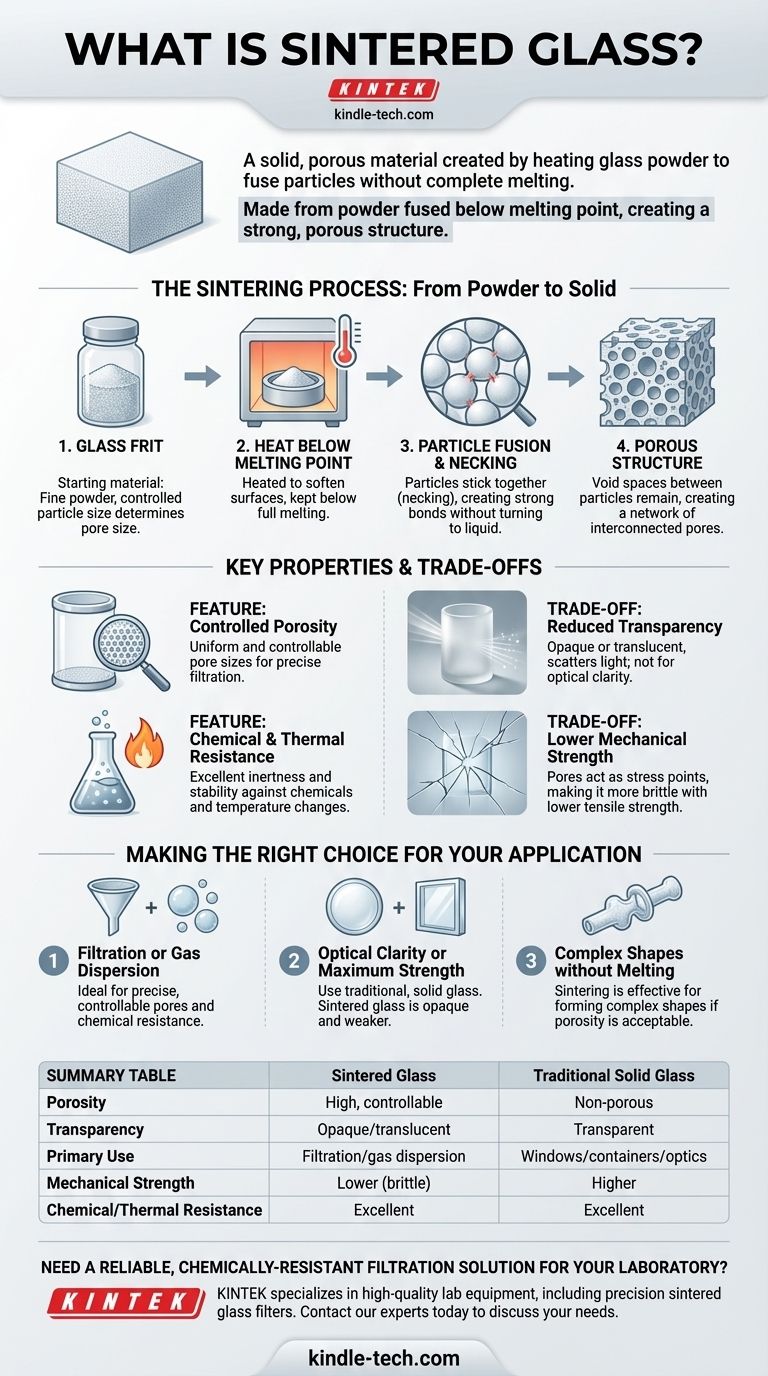

In essence, sintered glass is a solid, porous material created by heating glass powder to a temperature where the particles fuse together without completely melting. This process, known as sintering, transforms loose powder into a rigid, interconnected structure, much like welding countless tiny beads into a single, cohesive piece.

The critical distinction is that sintered glass is made from powder fused below its melting point, resulting in a strong but porous material, unlike traditional glass which is melted into a non-porous liquid and then cooled.

The Sintering Process: From Powder to Solid

Understanding how sintered glass is made is key to understanding its unique properties. It is a fundamentally different manufacturing path than that used for windows or bottles.

The Starting Material: Glass Frit

The process begins not with a sheet or a molten blob of glass, but with a fine powder known as glass frit.

The particle size of this frit is carefully controlled, as it will directly determine the pore size of the final product.

Applying Heat Below the Melting Point

This powder is placed in a mold and heated in a furnace. Critically, the temperature is raised high enough to soften the surfaces of the glass particles but kept below the glass's full melting point.

Particle Fusion and Necking

As the particles soften, they stick together at their points of contact. This localized fusion is called "necking," where small bridges or "necks" form between adjacent particles, creating a strong bond.

This is the core of the sintering process: welding particles together without turning the entire mass into a liquid.

The Result: A Porous Structure

Because the glass never fully melts and flows, the spaces between the original powder particles remain. These voids become a network of interconnected pores throughout the final solid material.

The result is a single, rigid piece of glass with a sponge-like internal structure.

Key Properties and Trade-offs

The unique manufacturing process of sintered glass gives it distinct advantages and disadvantages compared to its solid, non-porous counterpart.

Feature: Controlled Porosity

The primary benefit of sintered glass is its uniform and controllable porosity. By selecting the initial size of the glass frit, manufacturers can produce filters with very specific pore sizes, from very fine to coarse.

This property makes it invaluable for scientific and industrial filtration.

Feature: Chemical and Thermal Resistance

Sintered glass retains the excellent chemical inertness and thermal stability of the base glass it was made from (e.g., borosilicate). It can withstand corrosive chemicals and significant temperature changes without degrading.

Trade-off: Reduced Transparency

The internal porous structure scatters light extensively. Consequently, sintered glass is typically translucent or opaque, not transparent. It cannot be used for applications requiring optical clarity, like lenses or windows.

Trade-off: Lower Mechanical Strength

The pores within the structure act as microscopic stress concentration points. This means sintered glass is generally more brittle and has lower tensile strength than a solid piece of the same glass.

Making the Right Choice for Your Application

Choosing between sintered and traditional glass depends entirely on whether porosity is a required feature or a critical flaw for your goal.

- If your primary focus is filtration or gas dispersion: Sintered glass is the ideal choice due to its precise, controllable network of pores and chemical resistance.

- If your primary focus is optical clarity or maximum strength: You must use traditional, solid glass, as the porous nature of sintered glass makes it opaque and mechanically weaker.

- If your primary focus is creating a complex shape without melting: Sintering can be an effective method to form intricate glass components, provided that the resulting porosity is acceptable for the application.

Ultimately, sintered glass is an engineered material designed specifically for tasks where a durable, porous filter is essential.

Summary Table:

| Property | Sintered Glass | Traditional Solid Glass |

|---|---|---|

| Porosity | High, controllable pores | Non-porous |

| Transparency | Opaque or translucent | Transparent |

| Primary Use | Filtration, gas dispersion | Windows, containers, optics |

| Mechanical Strength | Lower (brittle) | Higher |

| Chemical/Thermal Resistance | Excellent (depends on base glass) | Excellent |

Need a reliable, chemically-resistant filtration solution for your laboratory?

At KINTEK, we specialize in high-quality lab equipment, including sintered glass filters designed for precision and durability. Our products are crafted to meet the rigorous demands of scientific filtration, ensuring consistent performance and chemical inertness.

Let us help you select the perfect porous glass for your application. Contact our experts today to discuss your specific needs and discover how KINTEK can enhance your lab's capabilities.

Visual Guide

Related Products

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- High Temperature Resistant Optical Quartz Glass Sheet

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

People Also Ask

- How do you clean a sputter target? Master the In-Situ Pre-Sputtering Process for Pristine Films

- What is the process of melting alloys? From Solidus to Liquidus for Precise Results

- What is the conductivity of graphite? Understanding Its High Electrical & Thermal Properties

- What are the basics of heat treating? Master Temperature, Time, and Cooling for Superior Metal Properties

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- How do you prepare samples for FTIR analysis? A Step-by-Step Guide to Clear, Accurate Spectra

- What is the standard for Aluminium heat treatment? Master the Temper Designation System for Optimal Properties

- What is the effect of heating rate in heat treatment? Control Hardness, Microstructure, and Distortion