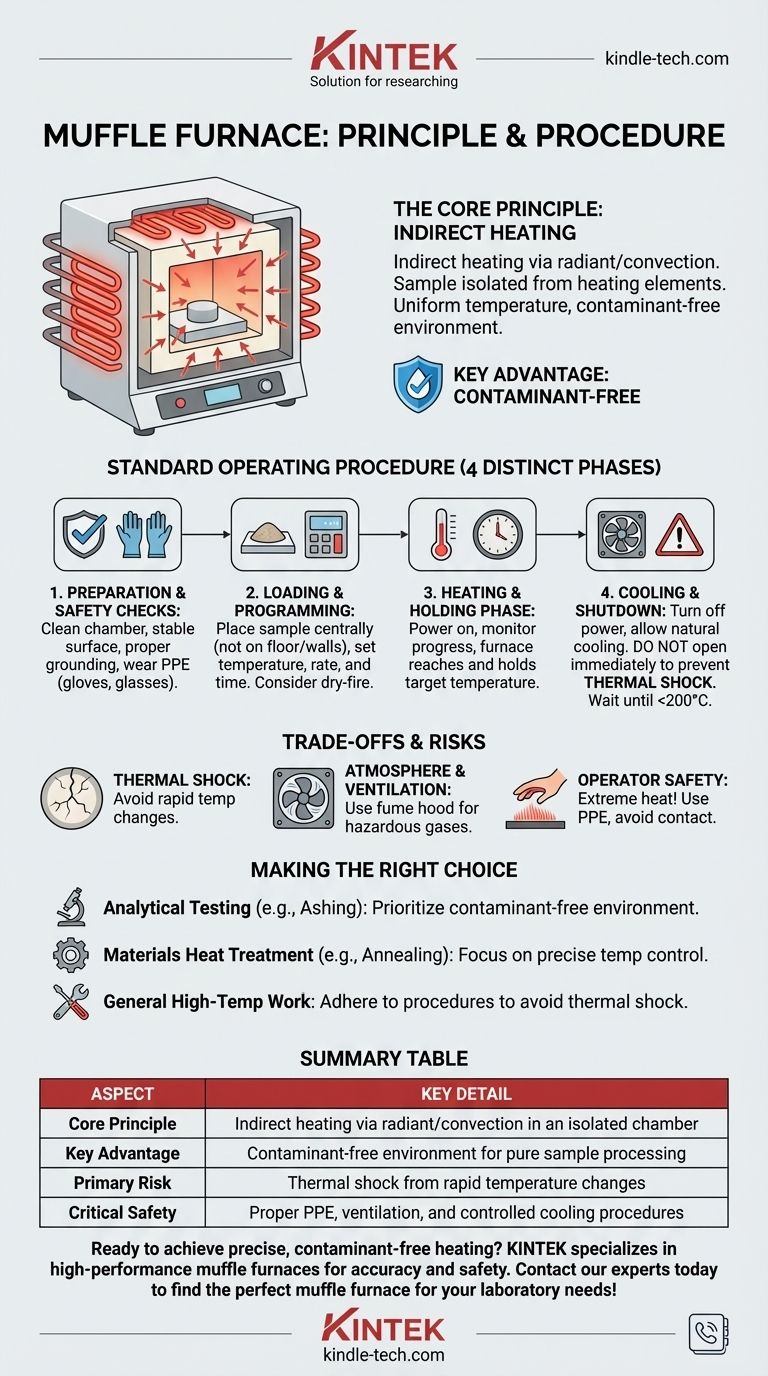

At its core, a muffle furnace operates on the principle of indirect heating. The material you wish to heat is placed inside a high-temperature chamber, or "muffle," which is then heated externally by electric resistance elements. This design completely isolates the sample from the heating elements, ensuring a clean, contaminant-free environment and highly uniform temperature distribution.

The essential purpose of a muffle furnace is to provide precisely controlled, high-temperature heating in a completely isolated environment. This separation protects your sample from contamination and ensures consistent, repeatable results, but requires strict adherence to procedures to manage extreme heat safely.

The Core Principle: Controlled Isolation

A muffle furnace is more than just a simple oven. Its design is engineered to solve the specific problem of achieving pure, uniform heat at very high temperatures.

What Defines the "Muffle"?

The "muffle" is the furnace's inner chamber, typically made of high-alumina refractory ceramics. This material is designed to withstand extreme thermal stress and is an excellent thermal conductor.

The heating elements are positioned outside this chamber, never coming into direct contact with the materials being processed.

How Heating is Achieved

The electric elements heat the muffle chamber itself. The chamber then radiates this heat uniformly inward, heating the sample through a combination of radiant and convection heat transfer.

This indirect method is the key to achieving a homogenous temperature profile throughout the entire processing area, preventing hot spots.

The Key Advantage: A Contaminant-Free Environment

Because the sample is completely sealed off from the heating elements, there is zero risk of contamination from the heat source.

This is critical for sensitive laboratory procedures like ashing, gravimetric analysis, or materials research, where the purity of the sample is paramount for accurate results.

Standard Operating Procedure

Following a systematic procedure is crucial for safety, equipment longevity, and the success of your work. The process can be broken down into four distinct phases.

Step 1: Preparation and Safety Checks

Before powering on the unit, perform a thorough pre-check. Ensure the furnace chamber is clean and free of any residue from previous runs.

Place the furnace on a stable, flat surface away from any flammable materials and ensure it is properly grounded. Always wear appropriate personal protective equipment (PPE), including heat-resistant gloves and safety glasses.

Step 2: Loading and Programming

Carefully place your samples into the center of the chamber, ensuring they are stable. Never place samples directly on the furnace floor or touching the walls, as this can impede airflow and cause damage.

Close the furnace door securely. Set the desired temperature and, if applicable, the heating rate and holding time on the temperature controller. For a new furnace or one that has been idle, an initial "dry-fire" without samples is recommended to burn off any residual impurities.

Step 3: The Heating and Holding Phase

Turn on the main power switch. The furnace will begin to heat up to your setpoint, often indicated by a light on the controller (e.g., green for heating).

Once the target temperature is reached, the furnace will enter a "holding" phase to maintain that temperature for the programmed duration. Monitor the process to ensure the temperature remains stable.

Step 4: Cooling and Shutdown

After the holding time is complete, turn off the power at the controller and then shut off the main power switch. Do not open the door immediately.

The furnace must be allowed to cool down gradually and naturally. Opening the door while the chamber is at a high temperature will cause thermal shock, which can crack the ceramic muffle and ruin your sample. Wait until the temperature has fallen to a safe level (typically below 200°C) before opening the door to remove your items.

Understanding the Trade-offs and Risks

While incredibly useful, the high temperatures involved in muffle furnace operation demand respect and an awareness of potential pitfalls.

Thermal Shock is the Primary Enemy

The most common cause of furnace damage is thermal shock. This occurs from heating or cooling the ceramic components too rapidly. Always follow a programmed heating ramp and, most importantly, allow for a slow, natural cool-down.

Atmosphere and Ventilation are Critical

Heating certain materials can release fumes or off-gas. Always operate the furnace in a well-ventilated area or under a fume hood to prevent the buildup of potentially hazardous gases.

Operator Safety is Non-Negotiable

The exterior of the furnace can become extremely hot. Never touch the furnace without proper PPE, and keep all combustible materials far away from the unit during operation. Strict adherence to safety protocols is the only way to operate this equipment.

Making the Right Choice for Your Goal

Your specific application will determine which principles and procedures are most critical to your success.

- If your primary focus is analytical testing (e.g., ashing): The principle of a contaminant-free environment is your main advantage; ensure the chamber is spotless before every run.

- If your primary focus is materials heat treatment (e.g., annealing metals): The principles of precise temperature control and uniform heating are essential for achieving the desired material properties.

- If your primary focus is general high-temperature work: Your priority must be the procedural and safety steps, particularly avoiding thermal shock to ensure the long-term reliability of the equipment.

By understanding the core principle of isolated heating and meticulously following the correct procedure, you can leverage the power of a muffle furnace safely and effectively.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Core Principle | Indirect heating via radiant/convection in an isolated chamber |

| Key Advantage | Contaminant-free environment for pure sample processing |

| Primary Risk | Thermal shock from rapid temperature changes |

| Critical Safety | Proper PPE, ventilation, and controlled cooling procedures |

Ready to achieve precise, contaminant-free heating in your lab?

KINTEK specializes in high-performance muffle furnaces and lab equipment designed for accuracy and safety. Whether you're conducting ashing, gravimetric analysis, or materials research, our solutions ensure uniform temperature control and reliable results.

Contact our experts today to find the perfect muffle furnace for your laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the importance of a muffle? Achieve Purity and Precision in High-Temperature Processes

- What are the environmental impacts of metal processing? A Guide to Sustainability and Solutions

- What is the use of muffle furnace in food analysis? Master Ashing for Accurate Mineral Content

- What is the difference between hot air oven and muffle furnace? Choose the Right Tool for Your Lab's Thermal Needs

- What precautions should you take while using a muffle furnace? Ensure Safe High-Temperature Processing in Your Lab