To start heat press printing, you need three core components: a heat press machine to provide heat and pressure, a method for creating your design (such as a vinyl cutter or a specialized printer), and the actual transfer material that will be applied to your product. The specific printer and materials you need are entirely dependent on the transfer method you choose, as each one is designed for different fabrics and outcomes.

Success in heat press printing isn't just about owning a press. It's about understanding that your equipment, materials, and transfer method are an interconnected system. The right choice depends entirely on what you want to create, the fabrics you'll use, and the level of quality you want to achieve.

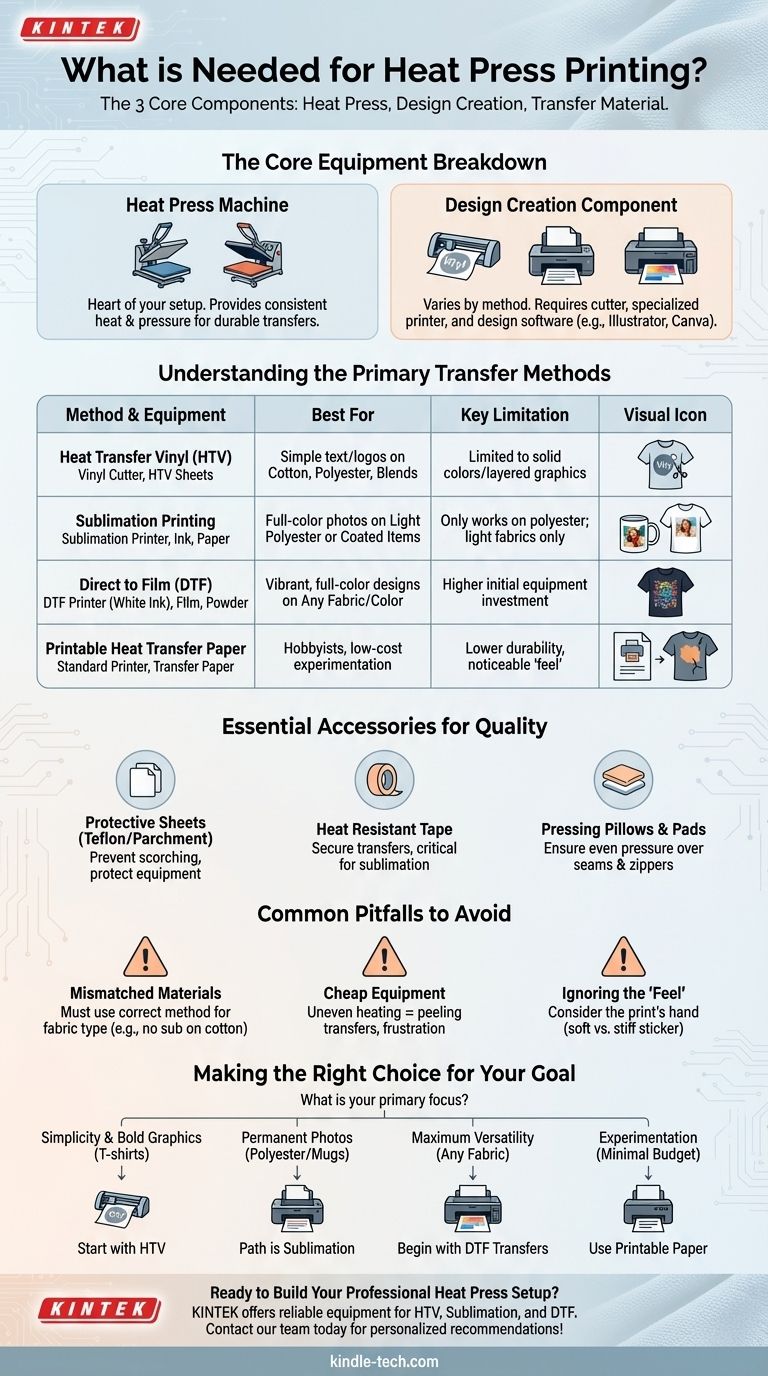

The Core Equipment Breakdown

Before you can press a single item, you need a foundational set of equipment. These tools are the engine of your operation, and investing wisely here prevents countless future frustrations.

Your Heat Press Machine

The heat press is the heart of your setup. Unlike a home iron, a dedicated press provides the consistent, high temperature and even pressure required for a durable, professional-looking transfer.

Presses primarily come in two styles: Clamshell, which opens like a mouth, and Swing-Away, where the top platen swings out to the side. Clamshells are space-efficient, while swing-away models provide better access to the work area and reduce the risk of touching the hot platen.

The Design Creation Component

You cannot press a design that doesn't exist. How you create that design dictates the rest of your required supplies. This is not a "one-size-fits-all" decision.

Your options range from a simple vinyl cutter for solid color graphics to highly specialized sublimation or Direct to Film (DTF) printers for full-color photographic images.

Design and Layout Software

You will need software to create or manipulate your designs before sending them to your cutter or printer.

Options include professional-grade software like Adobe Illustrator or CorelDRAW, user-friendly web-based tools like Canva, or the proprietary software that comes with vinyl cutters from brands like Cricut or Silhouette.

Understanding the Primary Transfer Methods

The transfer method you choose is the most critical decision, as it defines your printer, ink, and material requirements. Each method has distinct strengths and limitations.

Method 1: Heat Transfer Vinyl (HTV)

HTV involves cutting designs from pre-colored sheets of vinyl. The process is straightforward: cut your design with a vinyl cutter, "weed" away the excess material, and press it onto the garment.

- Required Supplies: A vinyl cutter, HTV sheets, a weeding tool.

- Best For: Simple text, logos, or layered single-color graphics. Works on cotton, polyester, and blends of various colors.

Method 2: Sublimation Printing

Sublimation uses special ink that, when heated, turns into a gas and chemically bonds with polyester fibers. The result is a print with zero feel that is incredibly durable and will never crack or peel.

- Required Supplies: A dedicated sublimation printer, sublimation ink, sublimation paper.

- Best For: Full-color, photo-realistic designs on light-colored, 100% polyester garments or specially coated hard goods like mugs and mousepads.

Method 3: Direct to Film (DTF) Transfers

DTF is a newer, highly versatile method. It involves printing a design (including a white ink base) onto a special film, coating it with an adhesive powder, and then pressing it onto the garment.

- Required Supplies: A DTF printer with DTF inks (C, M, Y, K, and White), DTF film, and DTF adhesive powder. Many users start by purchasing pre-printed transfers.

- Best For: Vibrant, full-color designs on any fabric type or color, including dark cotton and polyester.

Method 4: Printable Heat Transfer Paper

This is the most accessible entry point. You use a standard desktop printer to print your design onto a special heat transfer paper, which you then press onto your item. There are different papers for light and dark fabrics.

- Required Supplies: A standard inkjet or laser printer, and the correct heat transfer paper.

- Best For: Hobbyists, prototypes, or low-cost experimentation. The durability and feel are generally inferior to other methods.

Essential Accessories for Quality and Safety

Small accessories often make the difference between an amateur result and a professional one.

Protective Sheets

A Teflon sheet or sheet of parchment paper is non-negotiable. It protects your garment from direct contact with the hot platen, preventing scorching, and protects your press from any ink bleeding through the garment.

Heat Resistant Tape

This tape is used to secure your transfer in place on the item before pressing. It is absolutely critical for sublimation, where any shifting of the paper will cause a "ghosting" or blurry effect on the final print.

Pressing Pillows and Pads

These are foam-filled, Teflon-covered pillows placed inside a garment. They help ensure even pressure when pressing over seams, zippers, buttons, or collars, which would otherwise prevent the press from making full contact.

Understanding the Trade-offs and Common Pitfalls

Navigating the world of heat pressing means understanding the compromises inherent in each method. Avoiding common mistakes will save you significant time and money.

Pitfall 1: Mismatched Materials

This is the single most common failure point for beginners. You cannot sublimate on a 100% cotton shirt. You must use the correct transfer paper for dark fabrics if your shirt is not white. Every method has strict material requirements; ignoring them guarantees failure.

Pitfall 2: The Lure of "Cheap" Equipment

A low-quality heat press often has uneven heating and inconsistent pressure. This leads to transfers that peel after one wash, faded spots in your design, and immense frustration. Investing in a reputable press is cheaper in the long run than replacing wasted materials and garments.

Pitfall 3: Ignoring the "Feel" of the Print

A sublimation print has no "hand" or feel. An HTV design sits on top of the fabric. A print from transfer paper can feel like a stiff sticker. Consider the final user's experience when choosing your method, as the feel of the print is a major factor in perceived quality.

Making the Right Choice for Your Goal

Your starting point should be dictated by your end goal. Use this guide to determine your best path forward.

- If your primary focus is simplicity and creating bold graphics on t-shirts: Start with a quality heat press, a vinyl cutter, and Heat Transfer Vinyl (HTV).

- If your primary focus is creating permanent, full-color photos on polyester apparel or mugs: Your path is a complete sublimation setup (printer, ink, paper).

- If your primary focus is maximum versatility for full-color designs on any fabric color: Begin by ordering pre-printed DTF transfers to test the process before investing in a full DTF system.

- If your primary focus is experimenting on a minimal budget: Use your existing inkjet printer with the correct printable heat transfer paper, but be prepared for lower durability.

By matching your chosen method and materials to your specific goal, you are building the foundation for a successful and rewarding printing operation.

Summary Table:

| Transfer Method | Required Equipment | Best For | Key Limitation |

|---|---|---|---|

| Heat Transfer Vinyl (HTV) | Vinyl cutter, HTV sheets, weeding tool | Simple text/logos on cotton, polyester, blends | Limited to solid colors/layered graphics |

| Sublimation Printing | Dedicated sublimation printer, ink, paper | Full-color photos on light-colored polyester | Only works on polyester or coated substrates |

| Direct to Film (DTF) | DTF printer (with white ink), film, powder | Full-color designs on any fabric/color | Higher initial equipment investment |

| Transfer Paper | Standard inkjet/laser printer, transfer paper | Low-cost experimentation, prototypes | Lower durability, noticeable feel on fabric |

Ready to Build Your Professional Heat Press Setup?

Choosing the right equipment is crucial for achieving durable, high-quality transfers. At KINTEK, we specialize in providing reliable lab and production equipment to support your printing operations. Whether you're starting with HTV, upgrading to sublimation, or exploring DTF technology, we can help you select the right tools for your specific needs.

Our experts understand the unique requirements of heat press applications and can guide you toward equipment that delivers consistent results batch after batch. Let us help you avoid costly mistakes and build a setup that grows with your business.

Contact our team today for personalized equipment recommendations and pricing!

Visual Guide

Related Products

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Heat Press Machine

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Double Plate Heating Press Mold for Lab

People Also Ask

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- What is hot press laminate? A Durable, Non-Porous Surface Created by Heat and Pressure

- What is a hydraulic hot press machine? A Guide to Force and Heat for Material Transformation

- What is the purpose of using a hot press for sulfide solid-state electrolytes? Achieve Theoretical Density.

- How does a programmable hot press contribute to the manufacturing of NiO-YSZ anode supports for fuel cells?

- How long does a heat press machine last? Maximize Your Investment with the Right Choice

- Why is a laboratory hot press required for Oxygen Depolarized Cathodes? Ensure Precision Molding and Conductivity.

- What role does a benchtop hot press play in densifying composite cathodes? Achieve <10% Porosity with Thermo-Mechanical Flow