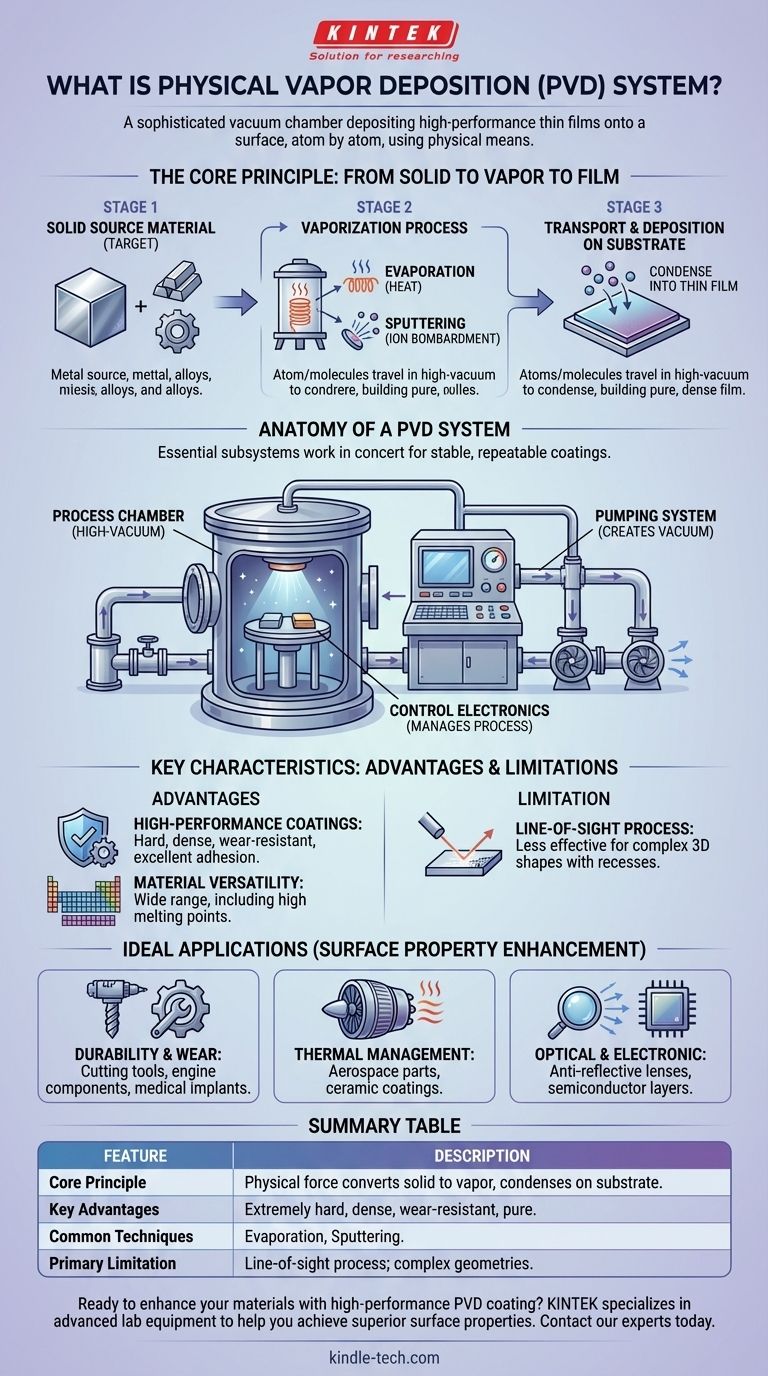

At its core, a Physical Vapor Deposition (PVD) system is a sophisticated vacuum chamber designed to deposit high-performance thin films onto a surface, atom by atom. The process involves taking a solid source material, converting it into a vapor through physical means like intense heat or ion bombardment, and allowing it to travel through the vacuum and condense onto the target object, known as the substrate. This method creates exceptionally pure, dense, and well-adhered coatings.

PVD is not a single process, but a family of vacuum deposition techniques. The unifying principle is the use of physical energy—not chemical reactions—to transport material from a source to a substrate, forming a functional or protective surface layer.

The Core Principle: From Solid to Vapor to Film

Understanding a PVD system begins with its fundamental three-stage process. This sequence is what allows for the precise construction of films just a few nanometers to several micrometers thick.

The Source Material (Target)

The process starts with a pure, solid material, often called a target or source. This is the material you intend to use for the coating, which can be anything from metals and alloys to ceramics and other compounds.

The Vaporization Process

This is the most critical step and defines the specific type of PVD. The solid material is converted into a gaseous vapor phase inside the vacuum chamber using physical force. The two primary methods are:

- Evaporation: The source material is heated in the vacuum until it evaporates, creating a vapor cloud. This can be done with simple resistance heating or more advanced methods like high-energy electron beams (e-beam evaporation).

- Sputtering: The source target is bombarded with high-energy ions (typically from an inert gas like argon) in a plasma. This atomic-scale "sandblasting" knocks atoms off the target's surface, ejecting them into the chamber.

Transport and Deposition

Once vaporized, the atoms or molecules travel in a straight line through the high-vacuum environment. When they strike the cooler substrate surface, they condense back into a solid state, gradually building up the desired thin film. Because this happens in a vacuum, the film is extremely pure and dense.

Anatomy of a PVD System

While designs vary, every PVD system is built around three essential subsystems that work in concert to ensure a stable and repeatable coating process.

The Process Chamber

This is the sealed, high-vacuum vessel where the entire deposition occurs. It houses the source material and the substrate, ensuring no unwanted atmospheric gases can contaminate the film.

The Pumping System

A powerful series of pumps is connected to the chamber to remove the air and create the necessary high-vacuum conditions. A larger chamber requires a more powerful pumping system to reach and maintain the low pressures required for the process.

The Control Electronics

This is the brain of the system. It manages and regulates all components, from the power supplied to the vaporization source to the gas flows and vacuum pressures. This precise control is what ensures the final coating is consistent and meets exact specifications.

Understanding the Trade-offs and Key Characteristics

PVD is a powerful technology, but it's essential to understand its specific advantages and limitations to know when to apply it.

Key Advantage: High-Performance Coatings

The primary reason to use PVD is the quality of the films it produces. They are known for being extremely hard, dense, and wear-resistant. They also exhibit excellent adhesion to the substrate and can provide superior protection against corrosion and high temperatures.

Key Advantage: Material Versatility

PVD can deposit a vast range of materials, including those with extremely high melting points that are difficult to process with other methods. This allows for the creation of coatings from pure metals, non-metals, alloys, and various compounds.

Key Limitation: Line-of-Sight Process

A crucial factor to consider is that PVD is fundamentally a line-of-sight process. The vaporized material travels in a straight line from the source to the substrate. This makes it ideal for coating flat or gently curved surfaces but less effective for complex, three-dimensional shapes with deep recesses or hidden areas.

Making the Right Choice for Your Application

Selecting PVD depends entirely on the surface properties you need to achieve. It is a solution for enhancing a material's performance in a specific way.

- If your primary focus is durability and wear resistance: PVD is an excellent choice for creating hard, dense coatings on cutting tools, engine components, and medical implants.

- If your primary focus is thermal management: PVD can apply specialized ceramic coatings that enhance the ability of aerospace parts to withstand extreme temperatures.

- If your primary focus is optical or electronic performance: PVD provides the precision needed to deposit anti-reflective films on lenses or conductive layers in semiconductors and solar panels.

Ultimately, a PVD system is a foundational tool for modern engineering, enabling the creation of advanced materials by precisely controlling their surface properties.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Converts a solid material into a vapor using physical force (heat, sputtering), which then condenses on a substrate to form a thin film. |

| Key Advantages | Produces extremely hard, dense, and wear-resistant coatings with excellent adhesion and purity. |

| Common Techniques | Evaporation, Sputtering. |

| Primary Limitation | Line-of-sight process; less effective for coating complex geometries with deep recesses. |

| Ideal Applications | Cutting tools, medical implants, aerospace components, semiconductors, optical lenses. |

Ready to enhance your materials with a high-performance PVD coating?

KINTEK specializes in advanced lab equipment, including PVD systems, to help you achieve superior surface properties. Whether you're developing more durable tools, precise optical components, or innovative electronic devices, our expertise can guide you to the right solution.

Contact our experts today to discuss how a PVD system can meet your specific laboratory or production needs and unlock new possibilities for your materials.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition