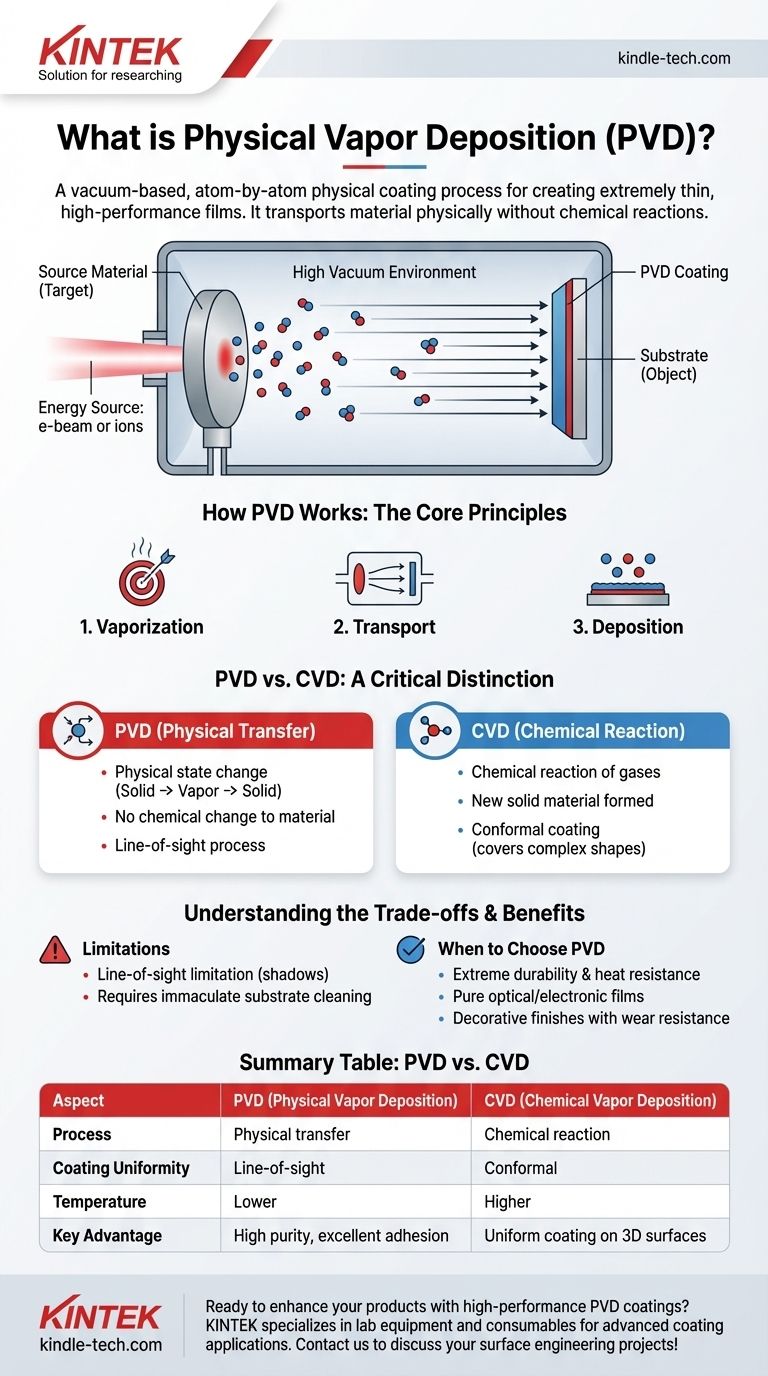

In essence, Physical Vapor Deposition (PVD) is a vacuum-based coating process where a solid material is vaporized and then deposited atom by atom onto a surface to create an extremely thin, high-performance film. Think of it as a highly controlled, atomic-level form of spray painting that occurs inside a vacuum chamber. The process physically transports material from a source to a substrate without a chemical reaction, resulting in coatings known for excellent adhesion and purity.

PVD is not about chemistry; it's about physics. The process physically transports material from a source to a target without chemical reactions, making it ideal for creating exceptionally pure, durable, and high-performance thin-film coatings on a wide variety of materials.

How PVD Works: The Core Principles

To understand PVD, it helps to break it down into its three fundamental stages: vaporization, transport, and deposition. This all happens within a controlled vacuum environment.

The Vacuum Environment

The entire PVD process is conducted under a high vacuum. This is critical because it removes air and other gas molecules that could otherwise contaminate the film or impede the movement of the vaporized atoms.

A clean, empty path ensures the coating material can travel directly from its source to the substrate, leading to a purer and more predictable film.

Vaporization of the Source Material

The coating material, known as the target or source, starts as a solid. This material is then converted into a vapor through purely physical means.

The two most common methods are:

- Evaporation: The target material is heated until it evaporates, releasing atoms into the vacuum chamber. This is often done using techniques like electron-beam evaporation for materials with very high melting points.

- Sputtering (Spraying): The target is bombarded with high-energy ions (typically from a gas like argon). This bombardment acts like an atomic-scale sandblaster, knocking atoms off the target surface and ejecting them toward the substrate.

Deposition onto the Substrate

The vaporized atoms travel through the vacuum chamber and condense onto the surface of the object being coated, which is called the substrate.

This atom-by-atom buildup forms a thin, dense, and highly uniform film. The properties of this film—such as its hardness, color, and resistance to wear—are determined by the source material and the specific process parameters used.

PVD vs. CVD: A Critical Distinction

While both PVD and Chemical Vapor Deposition (CVD) are used to create thin films, their underlying mechanisms are fundamentally different. Understanding this distinction is key to choosing the right process.

Physical Transfer (PVD)

In PVD, the material of the coating is the same material as the source. It is simply moved from one place (the target) to another (the substrate) in a different physical state (solid to vapor to solid).

There is no chemical change to the material itself during the process.

Chemical Reaction (CVD)

In CVD, the chamber is filled with one or more volatile precursor gases. These gases are not the final coating material.

Instead, a chemical reaction is induced on the substrate surface, causing the gases to decompose and form an entirely new solid material as the film.

Understanding the Trade-offs

PVD is a powerful technique, but it is not without its limitations. Objectively evaluating these trade-offs is essential for any technical application.

The Line-of-Sight Limitation

Because PVD physically transports atoms in a straight line, it is considered a line-of-sight process. This means it can be challenging to coat complex, non-planar geometries or the internal surfaces of a part uniformly.

Areas that are "in shadow" from the source will receive little to no coating material.

Substrate Preparation is Critical

The "good adhesion" noted in PVD is highly dependent on an immaculately clean substrate surface. Any microscopic contaminants like oils or oxides will prevent the film from bonding properly, leading to defects or delamination.

This means PVD requires a rigorous, multi-step cleaning process prior to coating.

Material and Temperature Considerations

PVD excels at depositing materials with high melting points that are difficult to handle with other methods. However, PVD processes are generally conducted at lower temperatures than many traditional CVD processes.

This can be an advantage for temperature-sensitive substrates, but it also means the resulting film's properties might differ from a high-temperature CVD equivalent.

When to Choose PVD for Your Application

PVD is not a one-size-fits-all solution; its strengths align with specific engineering goals. Use these guidelines to determine if it is the right choice for your project.

- If your primary focus is extreme durability and heat resistance: PVD is the industry standard for applying hard, temperature-resistant coatings on aerospace components and cutting tools.

- If your primary focus is creating pure, thin optical or electronic films: PVD provides the control needed to deposit precise optical and conductive layers for semiconductors and solar panels.

- If your primary focus is coating complex 3D shapes uniformly: You should consider CVD, as its gas-based nature allows it to deposit films more conformally over intricate surfaces.

- If your primary focus is decorative finishes with high wear resistance: PVD is widely used to create durable, metallic finishes on consumer products ranging from watches to plumbing fixtures.

By understanding PVD as a precise physical transfer process, you can effectively leverage it to engineer surfaces with unparalleled performance.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process | Physical transfer of material | Chemical reaction of gases |

| Coating Uniformity | Line-of-sight (shadows possible) | Conformal (covers complex shapes) |

| Temperature | Lower temperatures | Higher temperatures |

| Key Advantage | High purity, excellent adhesion | Uniform coating on 3D surfaces |

Ready to enhance your products with high-performance PVD coatings? KINTEK specializes in lab equipment and consumables for advanced coating applications. Whether you're in aerospace, electronics, or manufacturing, our expertise ensures durable, pure, and precise thin films tailored to your needs. Contact us today to discuss how our solutions can elevate your surface engineering projects!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition