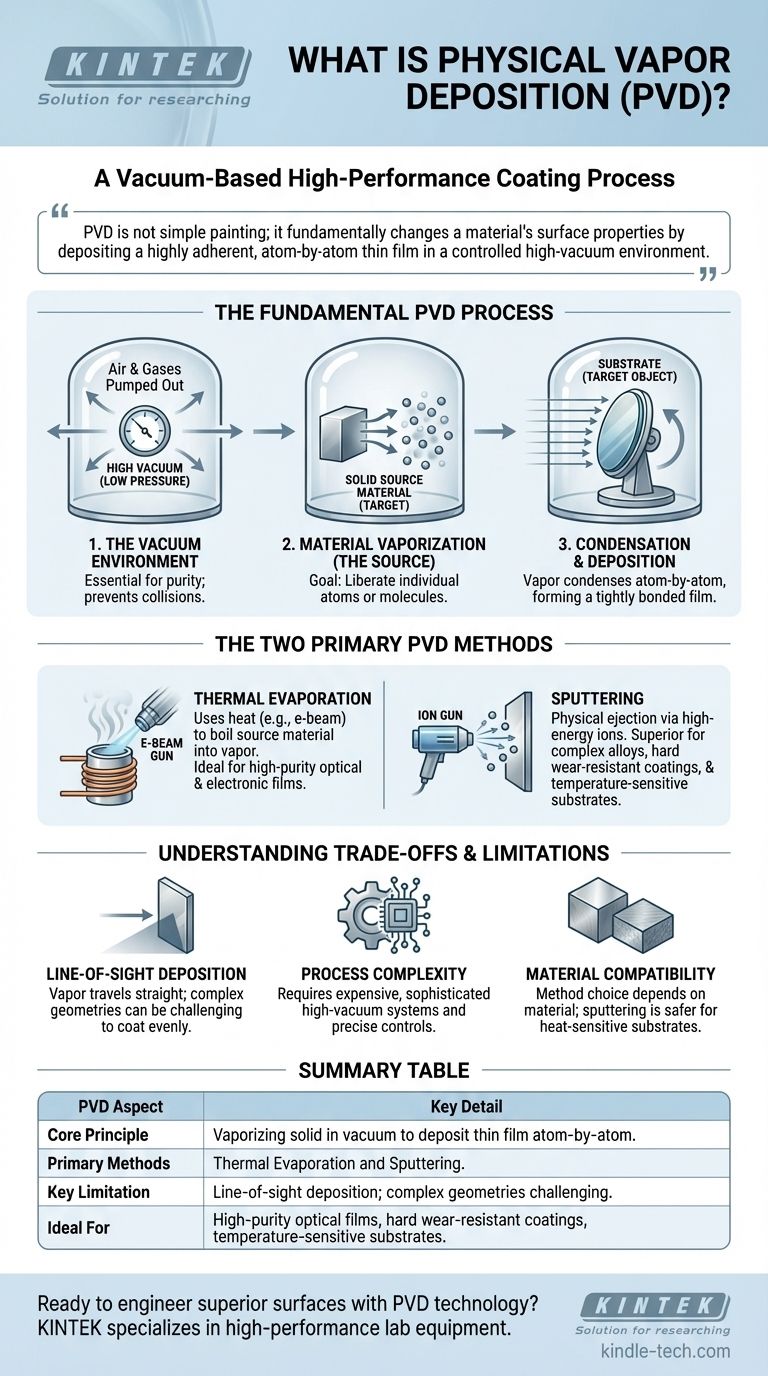

In essence, Physical Vapor Deposition (PVD) is a vacuum-based coating process where a thin, high-performance film is applied to a surface. The technique works by converting a solid source material into a vapor, which then travels through the vacuum and condenses onto the target object, building the coating one atom at a time.

PVD is not a simple painting or plating process; it is a sophisticated technique that fundamentally changes a material's surface properties by depositing a highly adherent, atom-by-atom thin film in a controlled high-vacuum environment.

How the PVD Process Fundamentally Works

The PVD process, regardless of the specific method used, follows three critical steps conducted inside a vacuum chamber. This environment is essential for the purity and quality of the final coating.

The Vacuum Environment

First, all the air and other gases are pumped out of the deposition chamber to create a high vacuum. This extremely low-pressure environment is critical because it prevents vaporized coating atoms from colliding with air molecules on their way to the substrate.

Material Vaporization (The Source)

A solid source material, known as the target, is converted into a vapor. This is the core step that defines the different types of PVD. The goal is to liberate individual atoms or molecules from the solid material so they can be transported.

Condensation and Deposition

The vaporized atoms travel in a straight line through the vacuum chamber and strike the surface of the component to be coated, which is called the substrate. Upon contact with the cooler substrate, the vapor condenses back into a solid state, forming a thin, dense, and tightly bonded film. Fixtures often rotate the parts to ensure an even coating on complex 3D surfaces.

The Two Primary PVD Methods

While the principle is the same, how the material is vaporized creates two distinct and common PVD categories.

Thermal Evaporation

This method uses heat to turn the source material into a vapor. The solid material is heated in a crucible until it literally boils and evaporates.

A common and precise form of this is e-beam evaporation, where a high-energy electron beam is focused on the target material, causing it to vaporize at a controlled rate. This is often used for creating highly pure optical and electronic films.

Sputtering

Sputtering does not rely on heat to vaporize the material. Instead, it is a physical ejection process.

High-energy ions (typically from an inert gas like argon) are accelerated and smashed into the target material. The impact has enough energy to physically knock atoms off the target's surface, launching them toward the substrate where they form the coating.

Understanding the Trade-offs and Limitations

PVD is a powerful technology, but it is essential to understand its operational constraints to apply it correctly.

Line-of-Sight Deposition

The vaporized atoms travel in a straight line from the source to the substrate. This means PVD is a "line-of-sight" process. Any surface not directly exposed to the vapor source will not get coated, which can be a challenge for components with complex geometries, holes, or deep recesses.

Process Complexity

PVD systems require high-vacuum chambers, sophisticated power supplies, and precise controls. This makes the equipment expensive and the process more complex to run compared to conventional coating methods like painting or electroplating.

Material Compatibility

The choice of PVD method is often dictated by the material being deposited. Some alloys or compounds can decompose at the high temperatures required for thermal evaporation, making sputtering the only viable option.

Making the Right Choice for Your Application

Selecting the correct PVD method depends entirely on the desired properties of the final coating and the nature of the substrate material.

- If your primary focus is high-purity optical or electronic films: Thermal evaporation often provides the cleanest and most controlled deposition for these sensitive applications.

- If your primary focus is a hard, dense, and wear-resistant coating: Sputtering is generally superior for depositing complex alloys and compounds used for tools and aerospace components.

- If your primary focus is coating a temperature-sensitive material: Sputtering can be performed at lower temperatures than thermal evaporation, making it a safer choice for plastics or other sensitive substrates.

By understanding these core principles, you can effectively leverage PVD to engineer high-performance surfaces tailored to your specific technical needs.

Summary Table:

| PVD Aspect | Key Detail |

|---|---|

| Core Principle | Vaporizing a solid material in a vacuum to deposit a thin film atom-by-atom. |

| Primary Methods | Thermal Evaporation and Sputtering. |

| Key Limitation | Line-of-sight deposition; complex geometries can be challenging. |

| Ideal For | High-purity optical films, hard wear-resistant coatings, and temperature-sensitive substrates. |

Ready to engineer superior surfaces with PVD technology? KINTEK specializes in providing high-performance lab equipment and consumables, including solutions for advanced coating processes. Our expertise can help you select the right PVD method for your specific application, ensuring durability and precision. Contact our experts today to discuss how we can support your laboratory's coating and material science needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the temperature range for CVD? It's Not a Single Number—It's Dictated by Your Materials

- What is thin film deposition in IC fabrication? Build the Core Layers of Your Microchip

- Which method of CNTs production leads to high quality nanotubes in large-scale? Chemical Vapor Deposition (CVD)

- What is the substrate for CVD process? Choosing the Right Foundation for Your Thin Film

- What is the primary function of a CVD system in LDIP preparation? Engineering Superhydrophobic Micro-Nano Structures

- What are the uses of bio-oil from pyrolysis? Unlock Its Potential as Fuel, Chemicals & More

- What is the deposition process gas? A Guide to CVD & PVD Gases for Thin Film Deposition

- What is the significance of chemical Vapour deposition? The Ultimate Guide to High-Purity Thin Films