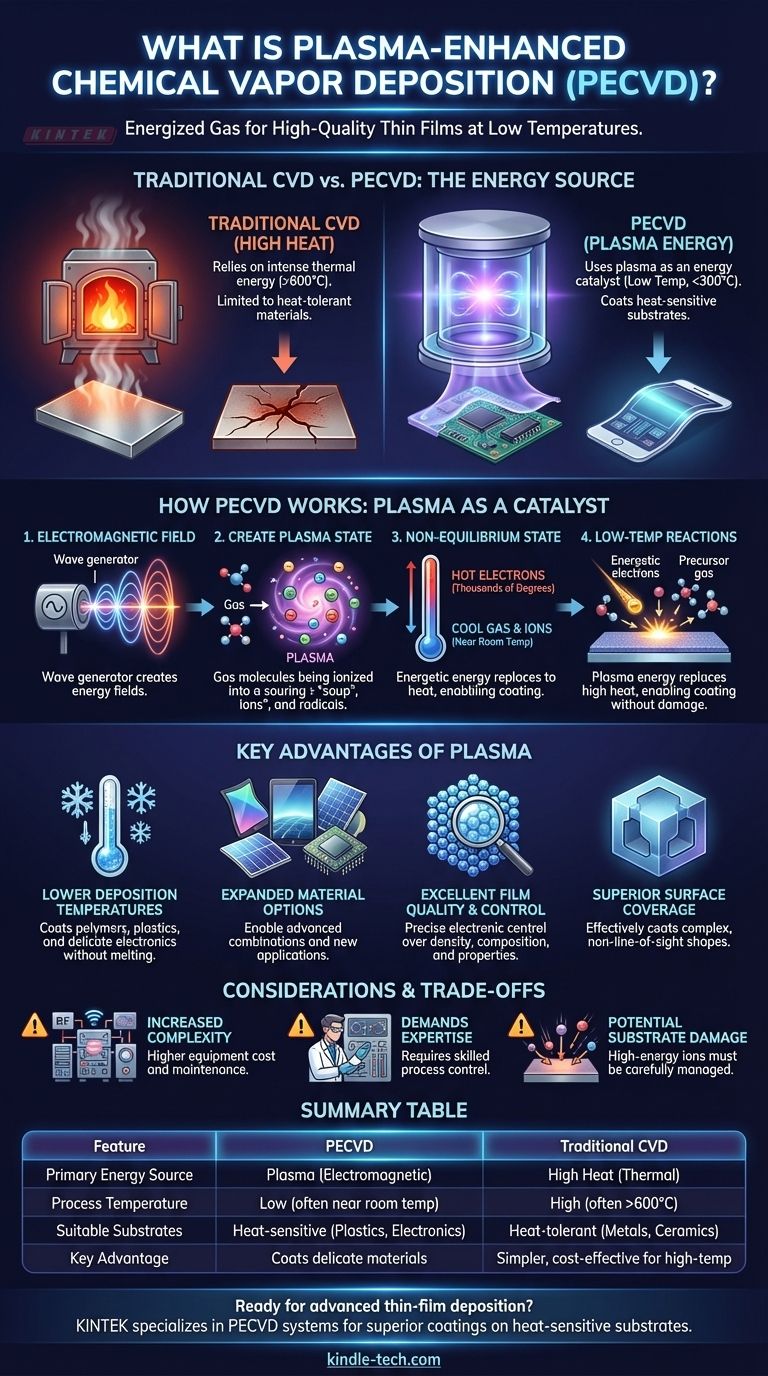

In short, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a process for creating high-quality thin films and coatings that uses an energized gas, or plasma, to drive the chemical reactions. Unlike traditional Chemical Vapor Deposition (CVD) which relies on high heat, PECVD uses the energy from the plasma to deposit films at significantly lower temperatures. This fundamental difference makes it possible to coat materials that would otherwise be damaged by heat.

The core problem with traditional thin-film deposition is its reliance on intense heat, limiting the types of materials you can coat. PECVD overcomes this by using plasma as an energy catalyst, enabling the creation of advanced coatings on heat-sensitive substrates like plastics and complex electronics.

How Traditional CVD Sets the Stage

To understand why plasma is a game-changer, we must first look at the conventional process it enhances.

The Basic Principle

In standard Chemical Vapor Deposition (CVD), a substrate (the part to be coated) is placed in a vacuum chamber. A precursor gas containing the desired coating elements is then introduced.

The gas reacts on the hot surface of the substrate, breaking down and depositing a solid, thin film.

The Thermal Energy Requirement

The critical factor in traditional CVD is heat. The substrate must be heated to very high temperatures to provide the thermal energy needed to break the chemical bonds in the precursor gas and initiate the coating reaction.

This high-heat requirement is its primary limitation, as it excludes any substrates that cannot withstand such temperatures.

The Role of Plasma: An Energy Catalyst

PECVD follows the same basic principle as CVD but revolutionizes the energy source. Instead of relying solely on heat, it injects energy into the gas using a plasma.

Creating the Plasma State

The process begins by applying a strong electromagnetic field (like microwave or radio-frequency) to the low-pressure gas in the chamber. This energizes the gas, stripping electrons from atoms and creating a highly reactive environment.

This energized gas, known as a plasma, is a "soup" of ions, electrons, free radicals, and other reactive species.

Hot Electrons, Cool Gas

The defining characteristic of PECVD plasma is its non-equilibrium state. The very light electrons can absorb immense energy, reaching temperatures of thousands of degrees (up to 5000 K or higher).

However, the heavier ions and neutral gas molecules remain much cooler, often near room temperature or a few hundred degrees. This means the overall process temperature stays low, protecting the substrate.

Enabling Low-Temperature Reactions

The highly energetic electrons and reactive radicals in the plasma collide with the precursor gas molecules. These collisions provide the energy to break chemical bonds and create the species needed for deposition.

Essentially, the plasma's energy replaces the thermal energy required in traditional CVD, allowing high-quality, dense films to be grown at a fraction of the temperature.

Understanding the Trade-offs and Considerations

While powerful, PECVD is not a universal solution. Its benefits come with specific complexities.

Increased System Complexity

A PECVD reactor is more complex than a thermal CVD system. It requires sophisticated hardware, such as microwave or RF power generators and impedance matching networks, to create and sustain the plasma. This adds to the equipment's cost and maintenance.

Demands for Expertise

Controlling the outcome of a PECVD process requires significant skill. The plasma chemistry is complex, and achieving the desired film properties—like density, composition, and stress—depends on a precise balance of gas flow, pressure, and plasma power.

Potential for Substrate Damage

While the overall temperature is low, the high-energy ions within the plasma can bombard the substrate surface. In some sensitive applications, this bombardment can cause structural damage, which must be carefully managed by fine-tuning the plasma conditions.

Key Advantages of Using Plasma

The ability to decouple the reaction energy from thermal heat provides several powerful advantages.

Lower Deposition Temperatures

This is the most significant benefit. PECVD enables coating on temperature-sensitive materials like polymers, plastics, and fully assembled electronic devices that would melt, warp, or be destroyed in a traditional CVD furnace.

Expanded Material and Substrate Options

By removing the high-heat constraint, a vast range of material combinations becomes possible. This has been critical for manufacturing thin-film solar cells, flexible electronics, and advanced semiconductor devices.

Excellent Film Quality and Control

PECVD can produce films that are highly pure, dense, and uniform. Because the process is controlled electronically (via plasma power) rather than thermally, engineers can precisely adjust the film's crystal structure, composition, and mechanical properties.

Superior Surface Coverage

The reactive species in the plasma can effectively coat complex, three-dimensional shapes, providing excellent "wrap-around" properties that are often superior to line-of-sight deposition methods.

Making the Right Choice for Your Goal

Selecting between traditional CVD and PECVD depends entirely on the constraints and objectives of your application.

- If your primary focus is coating heat-sensitive materials (like plastics or integrated circuits): PECVD is often the only viable choice due to its low-temperature operation.

- If your primary focus is depositing unique compounds (like amorphous silicon or silicon nitride): The specific reactive environment created by plasma is essential for forming the necessary chemical precursors that don't readily form with heat alone.

- If your primary focus is cost-effectiveness for a heat-tolerant substrate: Traditional thermal CVD might be a more straightforward and economical solution, as it avoids the complexity of plasma generation.

By understanding that plasma's primary role is to replace thermal energy, you can strategically choose the right deposition method for your specific material and application needs.

Summary Table:

| Feature | PECVD | Traditional CVD |

|---|---|---|

| Primary Energy Source | Plasma (electromagnetic field) | High Heat (Thermal) |

| Typical Process Temperature | Low (often near room temp) | High (often >600°C) |

| Suitable Substrates | Heat-sensitive materials (plastics, electronics) | Heat-tolerant materials (metals, ceramics) |

| Key Advantage | Enables coating of delicate materials | Simpler system, often more cost-effective for high-temp apps |

Ready to enhance your lab's capabilities with advanced thin-film deposition? KINTEK specializes in providing state-of-the-art lab equipment, including PECVD systems, to help you achieve superior coatings on even the most heat-sensitive substrates. Whether you're working with polymers, electronics, or complex 3D structures, our expertise ensures you get the right solution for your research or production needs. Contact us today to discuss how we can support your laboratory's innovation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is Microwave Electron Cyclotron Resonance Plasma Enhanced Chemical Vapour Deposition (MWECR-PECVD)? | KINTEK

- What role does a stainless steel bubbler play in RF-PECVD? Enhance Precursor Delivery for Siloxane Coatings

- What temperature is DLC application? Achieve Superior Coatings Without Damaging Your Parts

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the PECVD method? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the temperature of plasma deposition? Tailoring Your Process from Room Temp to 500°C

- How does the operating frequency of the RF power supply affect the PECVD process? Optimize Film Density & Uniformity

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition