In essence, positive compression molding is a high-precision manufacturing process where the raw material is placed in a mold cavity and fully trapped before pressure is applied. Unlike standard compression molding, this design prevents any excess material from escaping, forcing all of it to form the final part under direct pressure.

Positive molding is a trade-off: you exchange the simplicity and forgiveness of a standard "flash" mold for superior control over part density, minimal material waste, and the ability to form complex shapes. It is a technique chosen for precision, not speed.

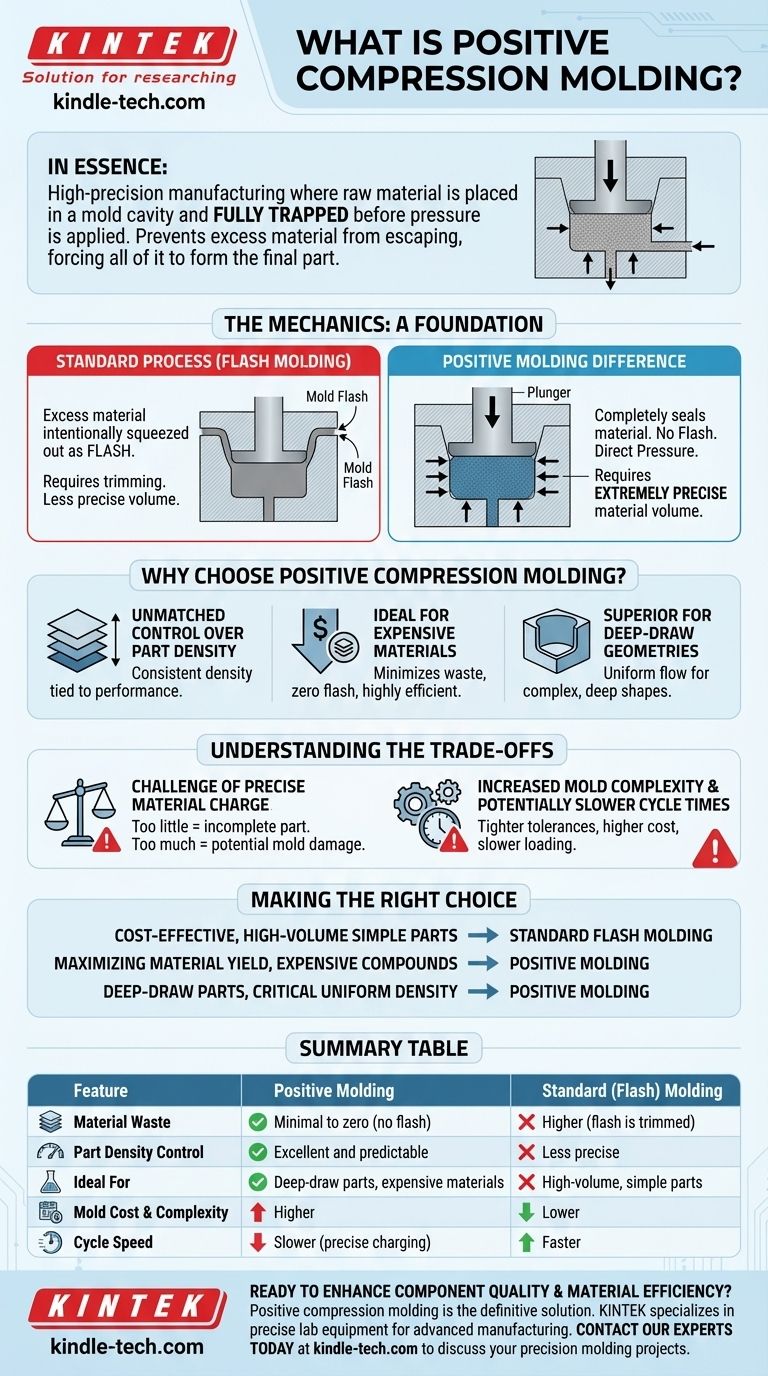

The Mechanics of Compression Molding: A Foundation

To understand positive molding, you must first understand the standard process it evolved from. Both methods use heat and pressure to shape a material charge, but how they manage volume and pressure is fundamentally different.

The Standard Process (Flash Molding)

In typical compression molding, a pre-measured amount of rubber or plastic, often slightly more than needed, is placed in the bottom half of a heated mold.

When the mold closes, pressure and heat cause the material to flow and fill the cavity.

Any excess material, known as mold flash, is intentionally squeezed out into small overflow grooves designed into the mold at the parting line. This flash is later trimmed from the finished part.

The Positive Molding Difference

Positive compression molding eliminates flash by design. The mold consists of a cavity and a matching plunger (or "force") that fits snugly inside it, much like a piston in a cylinder.

When the mold closes, the plunger enters the cavity and completely seals the material charge within it.

All the applied pressure acts directly on the material, forcing it to fill every detail of the mold. Because nothing can escape, the volume of the initial material charge must be extremely precise.

Why Choose Positive Compression Molding?

Engineers specify positive molding when part performance and material efficiency are more critical than raw production speed. The benefits directly address the limitations of standard molding.

Unmatched Control Over Part Density

Because all material is contained, the final density of the part is a direct and predictable result of the material volume and applied force. This is crucial for components where consistent density is tied to performance, such as seals or vibration dampeners.

Ideal for Expensive Materials

Positive molding is exceptionally efficient. With no material lost to flash, it minimizes waste. This makes it the superior choice when working with high-cost compounds like specialized elastomers, silicones, or advanced polymers where every gram saved impacts the bottom line.

Superior for Deep-Draw Geometries

A deep-draw part is one whose depth is greater than its diameter. Forcing material to flow into such a shape with standard molding is difficult and can lead to defects.

The direct pressure from the plunger in a positive mold acts like a hydraulic ram, ensuring the material flows evenly and completely fills these deep, complex cavities for a uniform and void-free part.

Understanding the Trade-offs

The precision of positive molding comes with specific operational challenges. It is not a universally superior method, and its drawbacks must be carefully considered.

The Challenge of Precise Material Charge

This is the single greatest challenge of positive molding. Since there is no overflow for excess material, the initial charge must be measured with extreme accuracy.

Too little material results in an incomplete, unusable part. Too much material can generate immense pressure, potentially damaging the mold or the press itself.

Increased Mold Complexity and Cost

The tight-fitting plunger-and-cavity design requires much tighter machining tolerances than a simple flash mold. This precision engineering makes the initial tooling more complex and therefore more expensive to produce.

Potentially Slower Cycle Times

The need to carefully weigh and load a precise material charge can slow down the overall production cycle. In contrast, flash molding allows for a faster, less precise loading process, prioritizing volume over per-part perfection.

Making the Right Choice for Your Application

The decision between positive and standard compression molding is a strategic one based on your project's unique priorities.

- If your primary focus is cost-effective, high-volume production of simple parts: Standard flash molding is almost always the more practical and economical choice.

- If your primary focus is maximizing material yield for expensive compounds: Positive molding's "no-waste" characteristic provides a clear financial and resource advantage.

- If your primary focus is creating deep-draw parts or components where uniform density is critical for performance: Positive molding is the essential technique to ensure part integrity and quality.

Ultimately, understanding this distinction empowers you to align your manufacturing process directly with your part's critical performance and cost requirements.

Summary Table:

| Feature | Positive Molding | Standard (Flash) Molding |

|---|---|---|

| Material Waste | Minimal to zero (no flash) | Higher (flash is trimmed) |

| Part Density Control | Excellent and predictable | Less precise |

| Ideal For | Deep-draw parts, expensive materials | High-volume, simple parts |

| Mold Cost & Complexity | Higher | Lower |

| Cycle Speed | Slower (precise charging required) | Faster |

Ready to enhance your component quality and material efficiency?

Positive compression molding is the definitive solution for applications demanding superior density control, complex geometries, and maximum material yield—especially when working with high-cost polymers and elastomers.

At KINTEK, we specialize in providing the precise lab equipment and consumables needed to support advanced manufacturing processes like positive molding. Our expertise helps laboratories and manufacturers achieve consistent, high-performance results.

Contact our experts today to discuss how we can support your precision molding projects and help you select the right equipment for your specific material and part requirements.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the difference between injection mold and insert mold? A Guide to Multi-Material Parts

- What is mold maintenance? A Proactive Strategy to Maximize Tool Lifespan and Quality

- What is the inside of a mold called? Understanding the Mold Cavity and Core

- What role do graphite molds play in NiCrAlY-Mo-Ag sintering? Enhance Precision and Density in Hot-Pressing

- What is the significance of applying different pressure levels during the assembly of all-solid-state batteries in molds?

- What is the role of high-purity graphite molds in vacuum hot pressing? Enhance Diamond Composite Matrix Precision

- What is a pellet die? A Guide to Creating Uniform Solid Samples from Powder

- What technical requirements must specialized pressure-bearing molds meet? Optimize Sulfide Electrolyte Densification