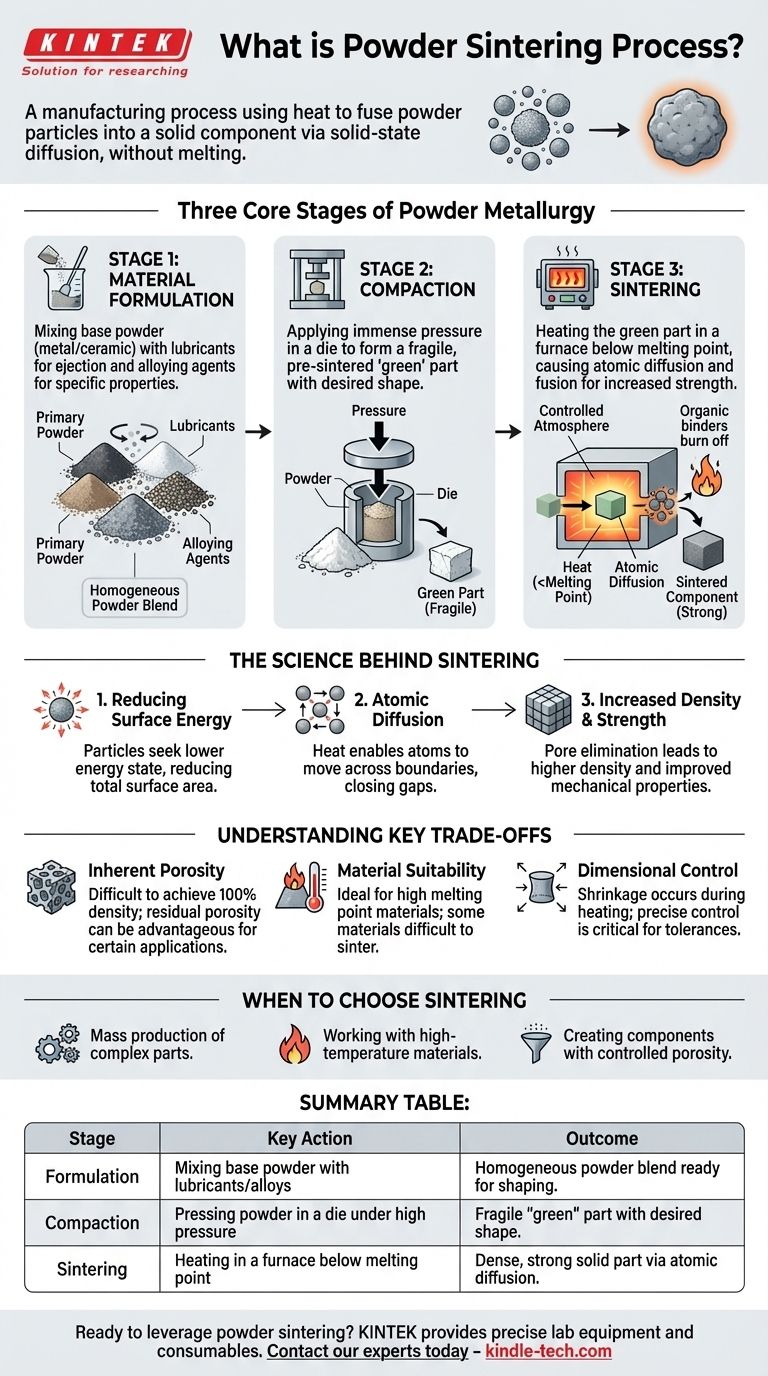

In essence, powder sintering is a manufacturing process that uses heat to fuse powder particles into a solid, strong component without melting the material. The process involves three main stages: formulating a specific powder blend, compacting it into a desired shape, and then heating this "green" part in a furnace to bond the particles together.

The core principle of sintering is not melting, but solid-state diffusion. Heat energizes the atoms in the powder particles, allowing them to move and bond across their contact points, which reduces porosity and dramatically increases the part's density and strength.

The Three Core Stages of Powder Metallurgy

The journey from loose powder to a finished component follows a precise and controlled path. Each stage is critical for achieving the final desired mechanical properties.

Stage 1: Material Formulation

Before any shaping can occur, the raw material must be prepared. This involves selecting a primary metal or ceramic powder, such as iron, copper, or nickel.

Other materials are often added to the mix. Lubricants are included to facilitate the ejection of the part from the die, and alloying agents can be introduced to achieve specific properties like hardness or corrosion resistance in the final product.

Stage 2: Compaction

The formulated powder is placed into a precision die and subjected to immense pressure. This mechanical force presses the particles into close contact, forming a fragile, pre-sintered object.

This object is known as a "green" part. It has the desired shape and dimensions but possesses very low strength, similar to a piece of chalk, and must be handled carefully.

Stage 3: Sintering

The green part is placed into a controlled-atmosphere furnace and heated to a high temperature, typically just below the material's melting point. This is the critical transformation step.

At these elevated temperatures, the organic binders and lubricants burn off first. Then, the particles begin to fuse together at their contact points through atomic diffusion, creating a solid, unified piece with significantly improved strength and hardness.

The Science Behind Sintering: How Does It Actually Work?

While the process seems straightforward, the transformation during the heating phase is driven by fundamental material science principles. It is a process of particles fundamentally seeking a more stable, lower-energy state.

The Driving Force: Reducing Surface Energy

Individual powder particles have a large amount of surface area, which corresponds to high surface energy. The universe favors lower energy states.

By heating the material, particles gain the mobility to bond together. This fusion reduces the total exposed surface area, thereby lowering the overall surface energy of the system and creating a more stable structure.

The Mechanism: Atomic Diffusion

Sintering works because heat provides enough energy for atoms to move, or diffuse, across the boundaries between touching particles. This is a solid-state process; no melting occurs.

This atomic movement closes the gaps and pores between particles. The points of contact grow into solid "necks," which pull the particle centers closer together, causing the entire part to shrink slightly and become much denser.

The Result: Increased Density and Strength

The direct outcome of this atomic bonding and pore elimination is a significant increase in the material's density. As the void spaces diminish, the part becomes more solid and robust.

This densification is directly linked to the improvement of mechanical properties. The final sintered component is far stronger, harder, and more durable than the initial green part.

Understanding the Key Trade-offs

Sintering is a powerful technology, but it's essential to understand its inherent characteristics and limitations to apply it correctly.

Inherent Porosity

It is very difficult to achieve 100% density through sintering alone. Most sintered parts will retain a small amount of residual porosity. While this can be a disadvantage for applications requiring absolute density, it can be an advantage for products like self-lubricating bearings or filters.

Material Suitability

The process is exceptionally well-suited for materials with very high melting points, such as ceramics and refractory metals, which are difficult or impossible to process via casting. However, not all materials are easily sintered.

Dimensional Control

While sintering is considered a net-shape or near-net-shape process, the part shrinks during the heating phase. Predicting and controlling this shrinkage is critical for achieving tight dimensional tolerances on the final component.

When to Choose Sintering

Your choice to use powder sintering should be driven by the specific goals of your project.

- If your primary focus is mass production of complex parts: Sintering is an excellent, cost-effective method for creating large volumes of small, intricate metal components with minimal machining required.

- If your primary focus is working with high-temperature materials: It is one of the few viable methods for shaping ceramics and metals with extremely high melting points into functional parts.

- If your primary focus is creating components with controlled porosity: Sintering provides a unique ability to design parts, like filters or bearings, where a specific level of interconnected porosity is a desired feature.

Ultimately, sintering provides a powerful and versatile method for transforming simple powders into robust, precision-engineered components.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Formulation | Mixing base powder with lubricants/alloys | Homogeneous powder blend ready for shaping |

| 2. Compaction | Pressing powder in a die under high pressure | Fragile "green" part with desired shape |

| 3. Sintering | Heating in a furnace below melting point | Dense, strong solid part via atomic diffusion |

Ready to leverage powder sintering for your lab's unique needs? KINTEK specializes in providing the precise lab equipment and consumables essential for every stage of the powder metallurgy process, from formulation to sintering. Whether you are mass-producing complex metal components or working with high-temperature ceramics, our expertise ensures you achieve the desired density, strength, and dimensional control. Contact our experts today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- How does a vacuum hot pressing sintering furnace facilitate the high densification of Al-30%Sc alloys?

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.

- What is the pressure for vacuum sintering? Achieve Optimal Material Purity and Density

- What are the advantages of using a vacuum hot pressing furnace? Achieve 98.9% Density in Al2O3-TiC Laminated Ceramics