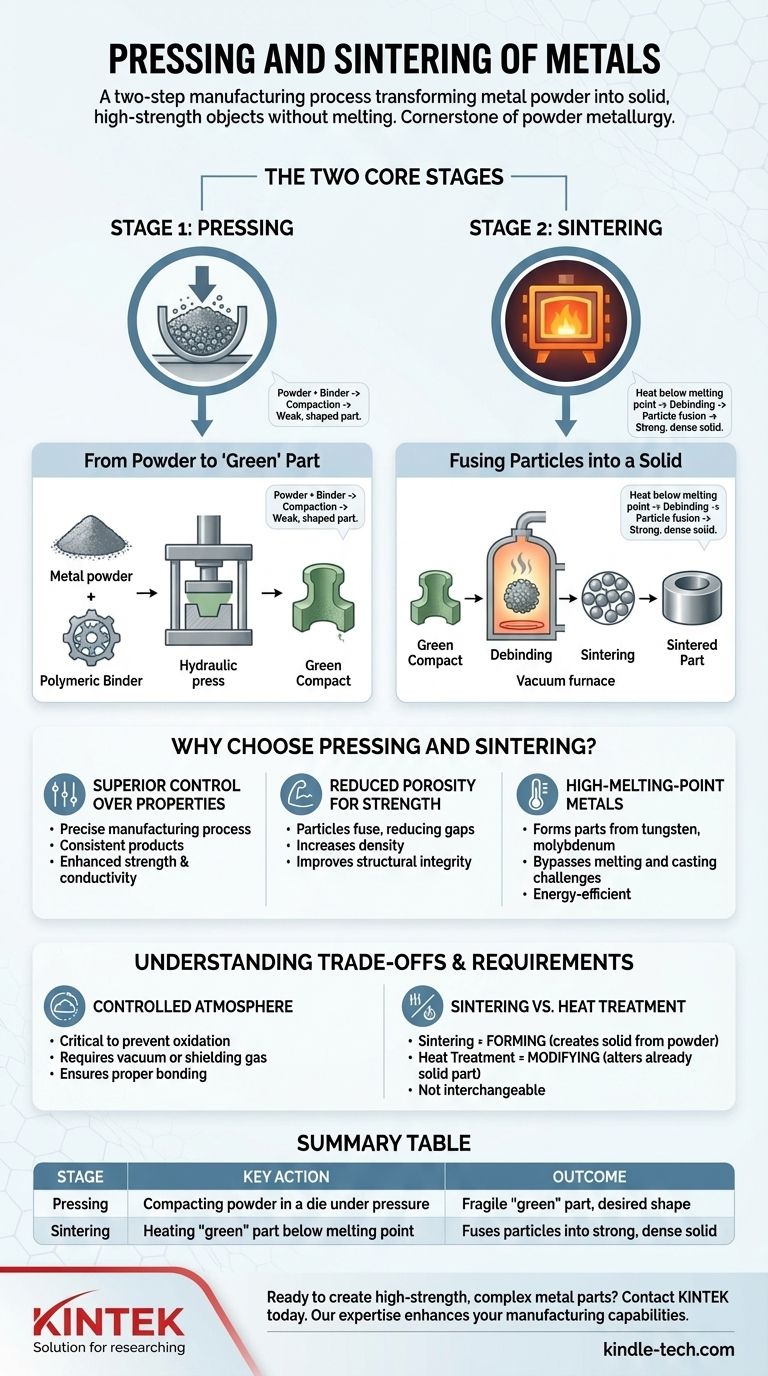

In short, pressing and sintering is a manufacturing process that turns metal powder into a solid, high-strength object without melting it. The process involves two main steps: first, metal powder is compacted under high pressure into a desired shape (pressing), and then this shape is heated in a controlled environment to a temperature just below its melting point, causing the individual particles to bond together (sintering).

This technique is the cornerstone of powder metallurgy. It allows engineers to create strong, complex metal parts—especially from materials with very high melting points—by fusing powder particles together, offering exceptional control over the final product's density and structural integrity.

The Two Core Stages of the Process

The entire method hinges on a sequence of precise, controlled actions that transform loose powder into a dense, functional component.

Stage 1: Pressing - From Powder to "Green" Part

The initial step involves creating a fragile, preliminary version of the final part, often called a "green" compact.

To achieve this, metal powder is often mixed with a polymeric binder, such as paraffin wax. This binder acts as a temporary glue, helping the particles stick together during compaction.

This mixture is then poured into a die and compressed under immense pressure. The result is a weakly-bonded part that has the desired shape but lacks the strength for any practical application.

Stage 2: Sintering - Fusing Particles into a Solid

This is where the transformation into a strong, metallic object occurs. The "green" part is placed inside a specialized furnace, typically a graphite furnace operating under a vacuum or with a controlled gas flow.

Before sintering begins, a "debinding" phase gently heats the part to burn off the polymeric binder.

The temperature is then raised to the sintering point, which is below the metal's melting point. At this high temperature, the atoms at the surfaces of the metal particles become highly mobile, diffusing across the boundaries and creating powerful metallic bonds between them.

Why Choose Pressing and Sintering?

This process is not just an alternative to casting or machining; it offers unique advantages that make it the ideal choice for specific applications.

Superior Control Over Final Properties

Sintering allows for exceptional control over the manufacturing process. By carefully managing powder composition, pressing force, and furnace conditions, engineers can produce highly consistent products.

This level of precision enhances critical properties like strength, durability, and electrical conductivity.

Reducing Porosity for Increased Strength

The initial "green" part is porous, full of tiny gaps between the powder particles. The sintering process significantly reduces this porosity by pulling the particles together.

Minimizing these internal voids dramatically improves the object's density, overall strength, and structural integrity.

Working with High-Melting-Point Metals

One of the most significant benefits of sintering is its ability to form parts from metals with extremely high melting points, such as tungsten or molybdenum.

Melting and casting these materials is technically challenging and energy-intensive. Sintering bypasses melting altogether, making it a more practical and efficient method.

Understanding the Trade-offs and Requirements

While powerful, the process is not universally applicable and has specific requirements for success. It is fundamentally different from other common metal treatments.

The Need for a Controlled Atmosphere

Sintering must be performed in a controlled atmosphere, such as a vacuum or with a shielding gas (like an endothermic gas).

This is critical to prevent the hot metal surfaces from oxidizing or becoming contaminated. Oxidation would form a barrier between the particles, preventing them from bonding properly and resulting in a weak, useless part.

Sintering Creates, Heat Treatment Modifies

It's important not to confuse sintering with other heat treatments like annealing, tempering, or quenching.

Those processes are applied to an already solid metal object to alter its properties—for example, to make it softer (annealing) or harder (quenching). Sintering, by contrast, is a forming process that creates the solid object from powder in the first place.

Making the Right Choice for Your Goal

Deciding whether to use pressing and sintering depends entirely on your material, the complexity of the part, and your production goals.

- If your primary focus is manufacturing parts from high-melting-point metals: Pressing and sintering is an ideal solution that avoids the complexities of liquid-phase processing.

- If your primary focus is mass production of complex, net-shape parts: This method offers excellent consistency and control, often minimizing the need for costly post-machining.

- If your primary focus is controlling the final density and porosity of a component: Sintering provides a unique level of precision over these microstructural properties for specialized applications.

Ultimately, pressing and sintering is a powerful manufacturing tool that transforms metal powder into high-performance components with precision and reliability.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| Pressing | Compacting metal powder in a die under high pressure | Creates a fragile "green" part in the desired shape |

| Sintering | Heating the "green" part below its melting point in a controlled atmosphere | Fuses powder particles into a strong, dense solid object |

Ready to create high-strength, complex metal parts with precision?

At KINTEK, we specialize in providing the advanced lab equipment and consumables necessary for successful pressing and sintering processes. Whether you are working with high-melting-point metals like tungsten or require exceptional control over density and porosity, our solutions are designed to meet the exacting needs of modern laboratories.

Contact us today to discuss how our expertise can enhance your manufacturing capabilities and help you achieve superior results.

Visual Guide

Related Products

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Manual Cold Isostatic Pressing Machine CIP Pellet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- Why do intrinsic self-healing polymers require heating? Unlock Repeatable Repair with Thermal Activation

- What is the purpose of an Ultra Freezer in research laboratories? Preserve Samples for Future Discoveries

- What are the four stages of sintering? A Guide to Precise Material Densification

- Why were ULT freezers originally set to -80°C instead of -70°C? Uncover the Marketing History & Save Energy

- What is reactive magnetron sputtering? A Versatile Method for Thin-Film Synthesis

- What are the uses of sintering method? A Guide to Fabricating High-Performance Parts

- How long is the annealing process? A Guide to Timing for Perfect Material Properties

- How does molybdenum increase corrosion resistance? Strengthen Alloy Durability Against Pitting & Chlorides