At its core, Physical Vapor Deposition (PVD) coating is used to apply a thin, incredibly durable film onto a vast range of products. This process enhances properties like hardness, wear resistance, and visual appeal. You will find PVD coatings on everything from industrial drill bits and automotive pistons to luxury watches, surgical instruments, and household faucets.

The fundamental reason PVD is so widely adopted is its unique ability to deliver both high-performance functional benefits and superior aesthetic finishes on an exceptionally broad array of materials, from steel and titanium to plastics.

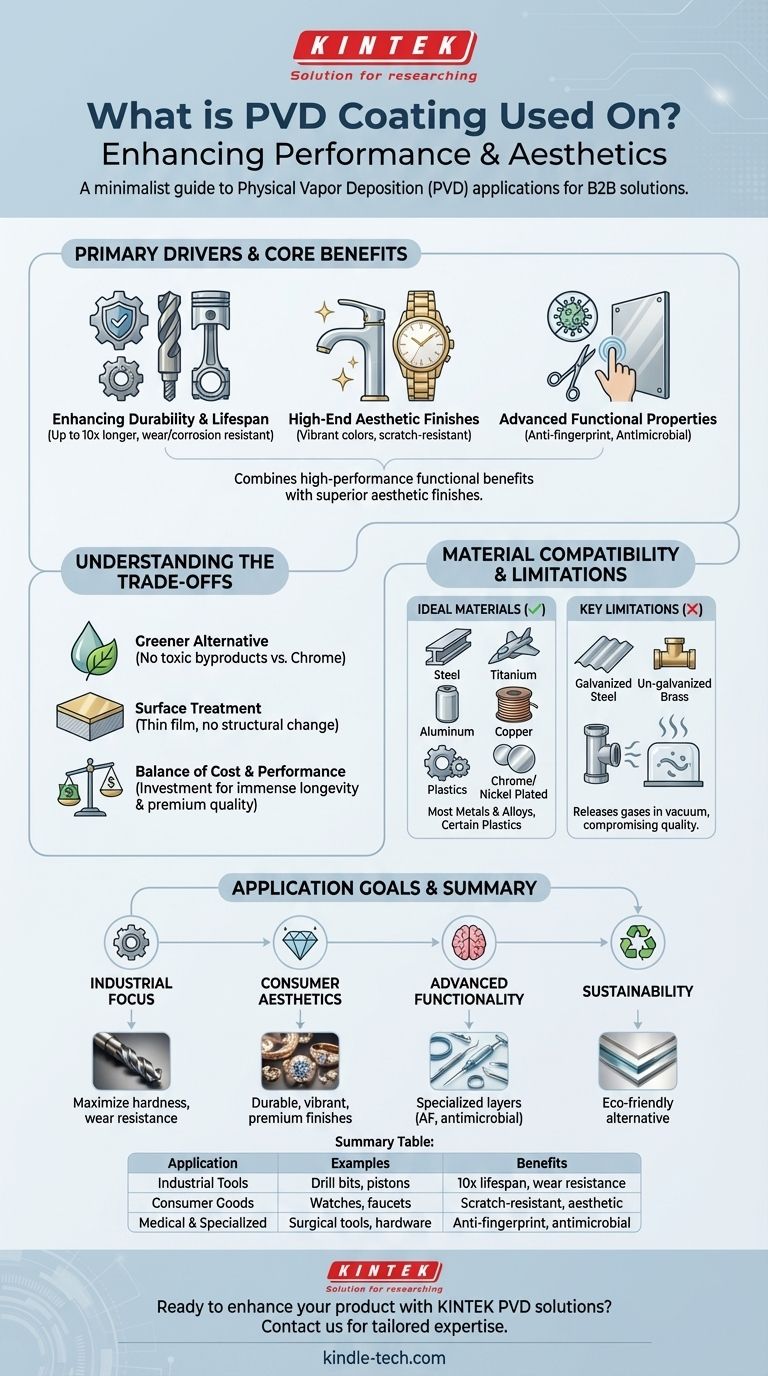

The Primary Drivers for PVD Adoption

Understanding why PVD is chosen reveals its true value. The decision to use this coating process is typically driven by the need to significantly improve a product's physical characteristics or its visual appeal—and often, both at the same time.

Enhancing Durability and Lifespan

The most common industrial use for PVD is to make products stronger and last longer. The coating acts as a protective barrier against wear, friction, and corrosion.

By applying a PVD finish, the lifespan of a product can be enhanced by up to ten times. This is critical for high-wear items like drill bits, automotive components such as pistons, and medical devices like surgical tools.

Achieving High-End Aesthetic Finishes

In the consumer goods market, PVD is prized for its ability to create beautiful, long-lasting colors and finishes. It provides a far more durable alternative to traditional plating or painting.

This is why it's commonly used on kitchen and bath fixtures, door hardware, and luxury items like watches and jewelry. For example, a gold-colored PVD coating on a stainless steel watch offers the look of solid gold with superior scratch resistance at a lower cost.

Adding Advanced Functional Properties

PVD technology allows for more than just durability and color. Specialized functional layers can be integrated directly into the coating process.

In architecture, PVD coatings are often combined with an anti-fingerprint (AF) layer, which is ideal for high-touch surfaces. Emerging research is also focused on in-chamber antimicrobial applications, which could be revolutionary for medical equipment and the food industry.

Material Compatibility: What Can and Cannot Be Coated

PVD is known for its versatility, adhering to a wide range of substrate materials. However, there are important limitations to consider.

Ideal Metals and Alloys

The process works exceptionally well with most metals. This includes all steel families (especially high-speed and stainless steels), titanium, aluminum, copper, and their alloys.

Products that have already been plated with chrome or nickel can also be successfully coated with PVD, often to add color or further improve durability.

Broader Material Scope

Beyond metals, PVD's compatibility extends to other material types. It can be successfully applied to certain plastics and even materials like gold, making it a flexible solution for complex product designs.

Key Material Limitations

The PVD process takes place in a vacuum, which makes some materials unsuitable. Specifically, galvanized materials and brass that has not been galvanized are poor candidates because they can release gases that interfere with the vacuum environment, compromising the coating quality.

Understanding the Trade-offs

While PVD is a powerful technology, it's essential to understand its context and what it is not. Acknowledging its trade-offs ensures it is used for the right application.

A Greener Alternative to Chrome Plating

A significant advantage of PVD is its environmental profile. Unlike traditional electroplating processes like chrome plating, the PVD process does not produce toxic chemical byproducts, making it a much cleaner manufacturing choice.

It's a Surface Treatment, Not a Structural Change

PVD adds a thin film—typically only a few microns thick—to the surface of a part. It dramatically improves surface properties but does not alter the underlying strength or flexibility of the substrate material itself.

The Balance of Cost and Performance

While PVD can create a cost-effective alternative to using solid precious metals, the process itself is a sophisticated industrial technique. The initial investment and processing costs must be weighed against the immense value it adds in product longevity and premium finish quality.

How to Apply This to Your Goal

Your specific objective will determine how you leverage PVD technology.

- If your primary focus is industrial performance: Use PVD to maximize the hardness, wear resistance, and lifespan of tools and mechanical components.

- If your primary focus is consumer aesthetics: Use PVD to create durable, vibrant, and premium finishes on products like hardware, jewelry, and electronics.

- If your primary focus is advanced functionality: Explore specialized PVD coatings to add properties like anti-fingerprint or antimicrobial layers for architectural and medical applications.

- If your primary focus is sustainability: Consider PVD as a high-performance, environmentally friendly alternative to traditional chemical plating processes.

Ultimately, PVD coating serves as a critical bridge between material science and product design, enabling the creation of items that are both more beautiful and more resilient.

Summary Table:

| Application Category | Common Examples | Key Benefits |

|---|---|---|

| Industrial Tools | Drill bits, pistons | Increases lifespan up to 10x, wear resistance |

| Consumer Goods | Watches, faucets, jewelry | Scratch-resistant, aesthetic colors, durability |

| Medical & Specialized | Surgical tools, architectural hardware | Anti-fingerprint, antimicrobial properties |

Ready to enhance your product's performance and appearance with advanced PVD coating? KINTEK specializes in lab equipment and consumables, providing tailored PVD solutions for industries ranging from medical to luxury goods. Our expertise ensures your products achieve superior durability, stunning aesthetics, and cutting-edge functional properties. Contact us today to discuss how KINTEK can meet your specific coating needs and elevate your product line!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating