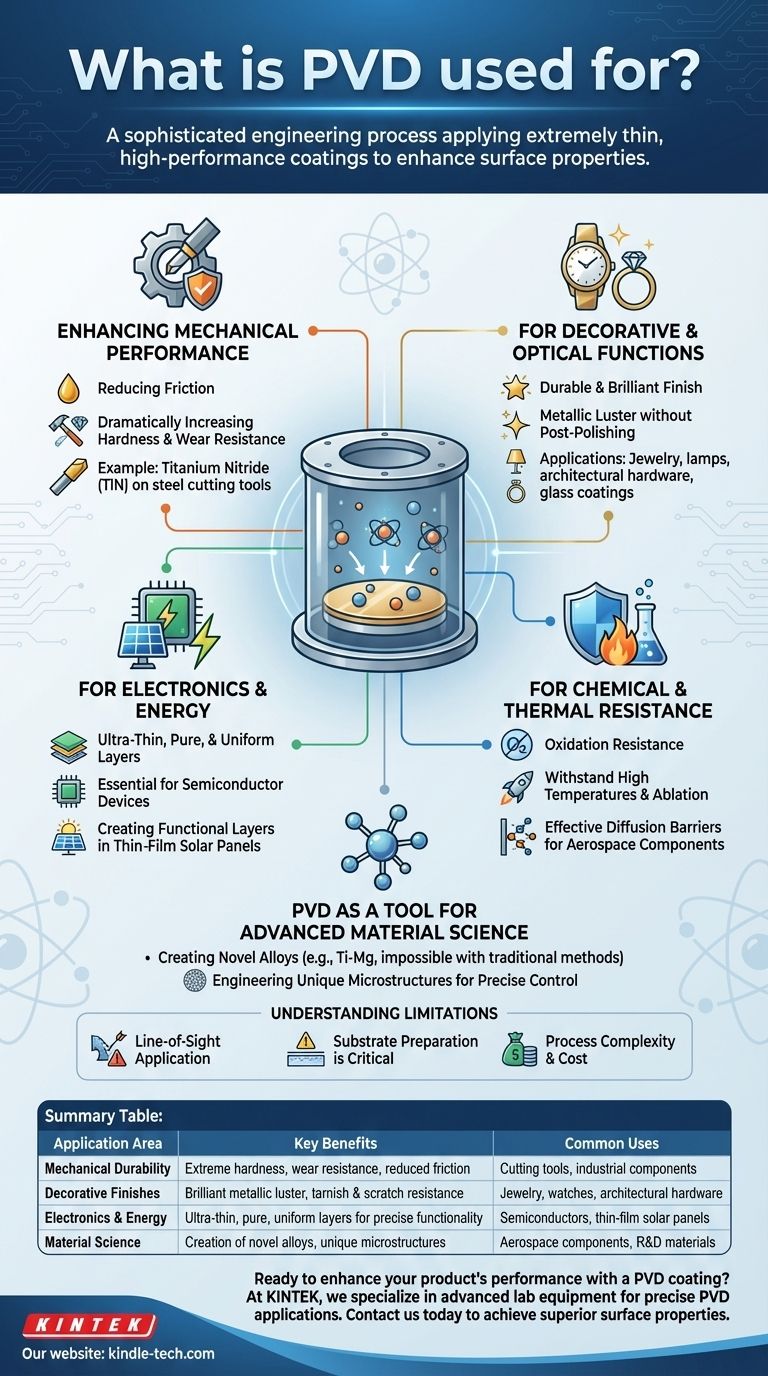

In essence, Physical Vapor Deposition (PVD) is used to apply an extremely thin, high-performance coating to a surface. This process is chosen to fundamentally alter the properties of an object, granting it enhanced hardness, wear resistance, corrosion resistance, or a specific aesthetic finish that the base material cannot achieve on its own.

PVD is not merely a cosmetic layer; it is a sophisticated engineering process that transforms a material's surface at a microscopic level. It is used when a product's performance or longevity is critically dependent on its surface characteristics.

The Core Principle: Enhancing Surface Properties

The fundamental purpose of PVD is to deposit a thin film of material—atom by atom—onto a substrate in a vacuum. This precision allows for the creation of coatings with specific, highly desirable properties.

For Mechanical Performance and Durability

PVD coatings are a primary method for improving the mechanical capabilities of a component. They create a new surface that is often far superior to the underlying material.

This is most commonly seen in reducing friction and dramatically increasing hardness and wear resistance. A classic example is the application of Titanium Nitride (TiN) to steel cutting tools, which allows them to last longer and perform better.

For Decorative and Optical Functions

PVD provides a durable and brilliant finish for a wide range of consumer and architectural products. It is prized for its ability to create a metallic luster without the need for post-polishing.

Applications include jewelry, kitchen and bathroom hardware, lamps, and other decorative items where both aesthetics and resistance to tarnishing and scratches are required. It is also used for glass coatings that can control light reflection or transmission.

For Electronics and Energy

The precision of PVD is critical in the manufacturing of high-technology devices. The process can deposit the ultra-thin, pure, and uniform layers required for modern electronics.

This is essential for fabricating semiconductor devices and creating the functional layers in thin-film solar panels.

For Chemical and Thermal Resistance

PVD films can act as a shield, protecting a substrate from its environment. This is a key reason for its use in demanding industries.

The coatings provide excellent oxidation resistance and can withstand high temperatures and ablation, making PVD a vital process for components used in aerospace technology. They can also serve as effective diffusion barriers, preventing materials from migrating into one another.

PVD as a Tool for Advanced Material Science

Beyond simple surface coatings, PVD is a sophisticated tool used to create entirely new materials that are impossible to produce with traditional methods like melting and casting.

Creating Novel Alloys

By co-depositing individual elements in a vacuum chamber, researchers can create unique alloy compositions.

For example, PVD can produce a titanium-magnesium (Ti-Mg) alloy, which cannot be made via traditional ingot metallurgy. This opens the door to new materials with unique properties.

Engineering Unique Microstructures

This deposition method results in materials with exceptionally fine grain sizes, extended solubility of elements, and a uniform composition free from the segregation common in cast metals. This gives engineers precise control over a material's final properties.

Understanding the Limitations

While powerful, PVD is not a universal solution. Understanding its trade-offs is crucial for making an informed decision.

Line-of-Sight Application

PVD is a line-of-sight process, meaning the coating material travels in a straight line from the source to the substrate. This can make it challenging to achieve a perfectly uniform coating on parts with complex internal geometries or deep crevices.

Substrate Preparation is Critical

The final PVD coating is only as good as the surface it is applied to. The substrate must be impeccably clean and smooth, as any imperfection or contaminant on the surface will be sealed in by the coating, potentially causing it to fail.

Process Complexity and Cost

PVD requires a high-vacuum environment and specialized, expensive equipment. This makes it a more complex and costly process compared to alternatives like painting or some forms of electroplating, restricting its use to applications where its high performance justifies the investment.

Making the Right Choice for Your Application

Selecting PVD depends entirely on the performance you need to achieve.

- If your primary focus is extreme durability and performance: PVD is the superior choice for adding hardness, lubricity, and wear resistance to critical tools and components.

- If your primary focus is a premium decorative finish: PVD provides a brilliant, long-lasting metallic coating for consumer products that is far more durable than traditional alternatives.

- If your primary focus is building advanced electronics: PVD is a non-negotiable, fundamental process for creating the precise thin-film layers required in semiconductors and solar cells.

- If your primary focus is materials innovation: PVD is a powerful research and development tool for creating novel alloys with properties unachievable through conventional metallurgy.

Ultimately, PVD is the definitive technology for engineering a surface to achieve goals that the bulk material alone never could.

Summary Table:

| Application Area | Key Benefits | Common Uses |

|---|---|---|

| Mechanical Durability | Extreme hardness, wear resistance, reduced friction | Cutting tools, industrial components |

| Decorative Finishes | Brilliant metallic luster, tarnish and scratch resistance | Jewelry, watches, architectural hardware |

| Electronics & Energy | Ultra-thin, pure, uniform layers for precise functionality | Semiconductors, thin-film solar panels |

| Material Science | Creation of novel alloys, unique microstructures | Aerospace components, R&D materials |

Ready to enhance your product's performance with a PVD coating?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise PVD applications. Whether you're developing cutting-edge electronics, durable industrial tools, or high-end decorative items, our solutions help you achieve superior surface properties that boost longevity and performance.

Contact us today to discuss how our expertise can support your specific laboratory needs and bring your projects to the next level.

Get in touch with our experts now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells