At its core, pyrolysis equipment is a system designed to break down materials, typically waste products like plastics, tires, or biomass, using high heat in an oxygen-free environment. This process, known as pyrolysis, doesn't burn the material but instead causes a thermal decomposition, converting the waste into valuable outputs like synthetic oil, gas, and a solid residue called bio-char.

This technology is best understood not as a disposal method, but as a chemical conversion process. Pyrolysis equipment acts as a refinery for waste, transforming low-value inputs into higher-value energy products and raw materials.

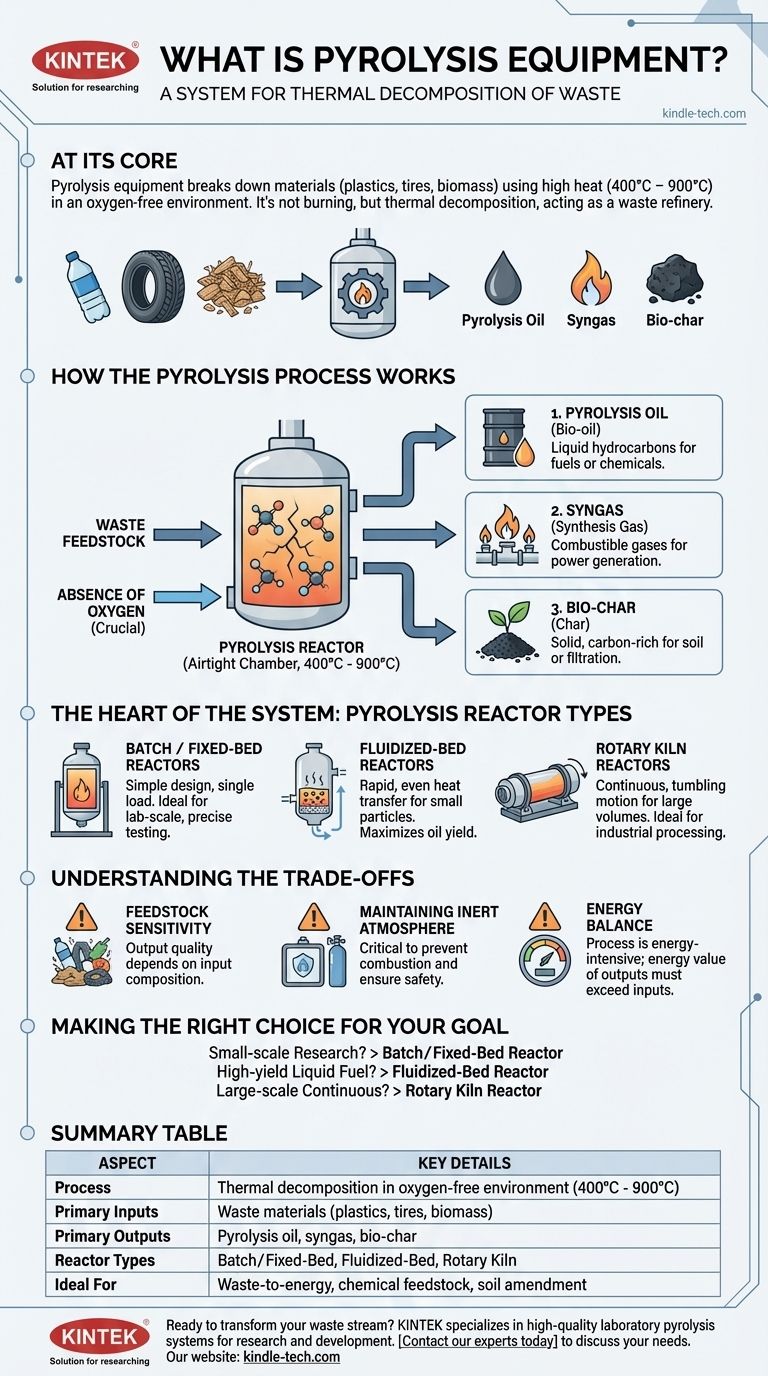

How the Pyrolysis Process Works

The fundamental goal of a pyrolysis plant is to precisely control heat and pressure on a given feedstock to break down its complex molecules into simpler, more useful ones.

The Core Principle: Thermal Decomposition

Pyrolysis equipment feeds waste material into an airtight chamber called a reactor. This reactor is then heated to very high temperatures, typically between 400°C and 900°C.

Crucially, this heating occurs in the absence of oxygen. This prevents combustion (burning) and instead forces the long-chain polymer molecules within the waste to crack and break apart.

The Three Primary Outputs

This decomposition process separates the feedstock into three distinct products:

- Pyrolysis Oil (Bio-oil): A liquid mixture of hydrocarbons similar to crude oil, which can be refined into fuels or used as a chemical feedstock.

- Syngas (Synthesis Gas): A mixture of combustible gases (like hydrogen and carbon monoxide) that can be used to power the pyrolysis plant itself or generate electricity.

- Bio-char (Char): A solid, carbon-rich material similar to charcoal. It can be used as a soil amendment to improve fertility, as a filtration medium, or as a solid fuel.

The Heart of the System: The Pyrolysis Reactor

While a full plant includes feeding mechanisms and control systems, the reactor is where the conversion happens. The type of reactor used depends heavily on the feedstock and the desired output.

Batch and Fixed-Bed Reactors

These are often the simplest designs, where a single load of material is processed at a time. A Heinz retort, for example, is essentially an airtight vessel heated from the outside like an oven.

These reactors are well-suited for laboratory-scale testing or small-batch processing where precise control over a single sample is needed.

Fluidized-Bed Reactors

This design is highly effective for processing small, uniform particles like woody biomass. The reactor contains a bed of inert material, such as sand, which is "fluidized" by a flow of hot, inert gas (like nitrogen) from below.

This creates a turbulent, boiling-like medium that ensures extremely rapid and even heat transfer to the feedstock. This efficiency often increases the yield of valuable bio-oils and gases.

Rotary Kiln Reactors

Used for larger, continuous industrial applications, a rotary kiln is a large, rotating cylindrical vessel. As the kiln slowly turns, it tumbles the waste material, ensuring it is mixed and heated evenly as it moves through the chamber.

This continuous motion makes it ideal for processing large volumes of material without interruption.

Understanding the Trade-offs

Pyrolysis is a powerful technology, but it comes with specific operational challenges that must be managed for successful implementation.

Feedstock Sensitivity

The system is not a universal solution for all waste. The chemical composition of the input material—whether it's plastic, tires, or agricultural waste—directly dictates the quality and proportion of the oil, gas, and char outputs.

Maintaining an Inert Atmosphere

The "absence of oxygen" is the most critical parameter of the entire process. Any air leaks into the high-temperature reactor can cause unwanted combustion, reducing efficiency and creating potentially hazardous conditions.

Energy Balance

The process itself is energy-intensive, requiring a significant thermal input to reach and maintain operating temperatures. A successful plant must be designed so the energy value of the outputs (especially the syngas used to power the system) exceeds the energy required to run it.

Making the Right Choice for Your Goal

The selection of pyrolysis equipment is driven entirely by the scale of the operation and the specific material being processed.

- If your primary focus is small-scale research or testing: A batch or fixed-bed reactor provides the controlled environment needed to analyze specific materials.

- If your primary focus is high-yield liquid fuel from fine particles: A fluidized-bed reactor is specifically designed for the rapid and efficient heat transfer required to maximize oil production.

- If your primary focus is large-scale, continuous industrial processing: A rotary kiln or similar continuous furnace offers the throughput and robust mixing needed for high-volume operations.

Ultimately, pyrolysis equipment provides a sophisticated pathway to unlock the stored energy and chemical value hidden within waste materials.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Thermal decomposition in an oxygen-free environment (400°C - 900°C) |

| Primary Inputs | Waste materials (plastics, tires, biomass) |

| Primary Outputs | Pyrolysis oil, syngas, bio-char |

| Reactor Types | Batch/Fixed-Bed, Fluidized-Bed, Rotary Kiln |

| Ideal For | Waste-to-energy, chemical feedstock production, soil amendment creation |

Ready to transform your waste stream into valuable resources?

KINTEK specializes in high-quality laboratory equipment, including pyrolysis systems for research and development. Whether you are testing new feedstocks or scaling up a process, our expertise can help you achieve precise thermal decomposition and maximize your output yields.

Contact our experts today to discuss how pyrolysis equipment can meet your specific laboratory or pilot-scale needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products