In essence, a fluidized bed reactor for pyrolysis is a system that uses a hot, turbulent bed of solid particles, like sand, to rapidly and uniformly decompose organic materials in an oxygen-free environment. An upward flow of inert gas, typically nitrogen, is forced through the sand, causing it to behave like a boiling liquid—a "fluidized" state. This creates an environment of extremely efficient heat transfer, which is the reactor's defining characteristic.

The core advantage of a fluidized bed reactor in pyrolysis is its ability to achieve exceptionally high and uniform heat transfer. This rapid heating maximizes the conversion of feedstock into valuable liquid products like bio-oil, a feat that simpler reactor designs cannot easily match.

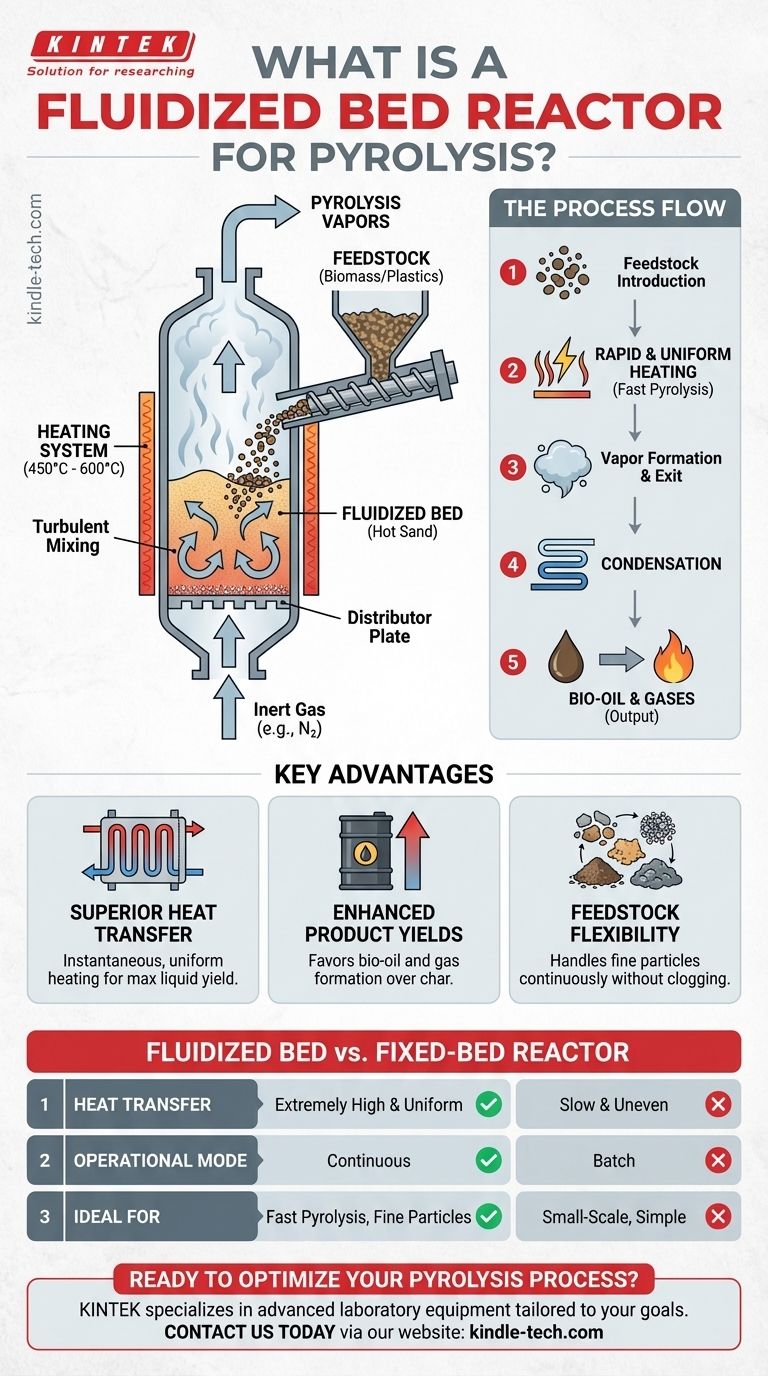

How a Fluidized Bed Reactor Works

To understand its value, we must first break down its mechanics. The process is a dynamic interplay between a solid medium, a gas, and the feedstock itself.

The Core Components

The reactor's operation relies on three key elements. First is the bed material, usually sand, which acts as a stable and efficient heat carrier.

Second is the fluidizing gas, an inert gas like nitrogen. This gas is critical as it prevents unwanted combustion and oxidation while simultaneously creating the fluidization effect.

Finally, a heating system brings the bed material to the high temperatures required for pyrolysis, typically ranging from 450°C to 600°C.

The "Fluidization" Phenomenon

The magic of this reactor is the fluidization itself. When the inert gas is forced up through the bed material at the right velocity, it lifts and separates the individual sand particles.

This causes the entire solid bed to swell and behave like a vigorously boiling fluid. It churns and mixes constantly, eliminating hot or cold spots within the reactor.

The Pyrolysis Reaction

Feedstock, such as fine particles of woody biomass or plastics, is introduced into this hot, turbulent environment. The instant it makes contact with the fluidized sand, it is heated rapidly and uniformly.

This process, known as fast pyrolysis, thermally cracks the material's large organic molecules into smaller, more valuable volatile compounds. These compounds exit the reactor as a vapor, which is then condensed to produce liquid bio-oil and non-condensable gases.

Key Advantages of Fluidized Bed Pyrolysis

The design of a fluidized bed reactor directly translates into significant process advantages, particularly for producing specific outputs.

Superior Heat Transfer

This is the most critical advantage. The constant, vigorous motion of hot sand particles ensures that feedstock heats to the target temperature almost instantaneously. This high heat transfer rate is essential for maximizing the yield of liquid products.

Enhanced Product Yields

The rapid heating rates characteristic of fast pyrolysis favor the formation of liquids (bio-oils) and gases over solid char. Fluidized bed reactors are specifically designed to optimize these conditions, increasing the yield of valuable byproducts compared to slower methods.

Feedstock Flexibility

The excellent mixing action makes these reactors highly effective for processing particulate substrates. They can handle a continuous flow of fine materials like sawdust, shredded plastic, or agricultural residues without the clogging issues that might affect other reactor types.

Understanding the Trade-offs and Comparisons

No technology is a universal solution. Understanding the trade-offs of a fluidized bed reactor is crucial for making an informed decision.

Comparison with Fixed-Bed Reactors

The most common alternative is the fixed-bed reactor, which has a much simpler design. In a fixed-bed system, the feedstock is stationary, and heat slowly diffuses inward from the reactor walls.

While simpler and cheaper to build, fixed-bed reactors suffer from slow and uneven heating. This results in lower liquid yields and is less efficient for continuous, large-scale processing. The fluidized bed's complexity is a direct trade-off for its superior performance and speed.

Operational Complexity

Maintaining a stable fluidized state requires precise control over gas flow rates, particle size, and temperature. The system is more mechanically complex than a fixed-bed reactor and requires more sophisticated control and monitoring to operate efficiently.

Common Applications

The unique capabilities of this reactor make it suitable for a range of industrial processes. It is a cornerstone technology for the thermal conversion of biomass, plastics, and various organic wastes.

Beyond biomass, principles from this technology are used in the petroleum industry, such as in fluid catalytic cracking (FCC), to produce high-value fuels from heavy oil fractions.

Making the Right Choice for Your Goal

Selecting the right reactor technology depends entirely on your specific objectives, feedstock, and desired products.

- If your primary focus is maximizing liquid yield (bio-oil) from fine particles: The rapid, uniform heat transfer of a fluidized bed reactor makes it the superior choice.

- If your primary focus is process simplicity and lower capital cost for batch operations: A fixed-bed reactor is a viable alternative, though you will sacrifice efficiency and liquid yield.

- If your primary focus is processing diverse or mixed feedstocks at a large scale: The excellent mixing and continuous operation of a fluidized bed reactor offer a distinct advantage.

Ultimately, a fluidized bed reactor is a highly engineered tool designed for speed and efficiency in thermal conversion.

Summary Table:

| Feature | Fluidized Bed Reactor | Fixed-Bed Reactor (Alternative) |

|---|---|---|

| Heat Transfer | Extremely high and uniform | Slow and uneven |

| Liquid Bio-Oil Yield | Maximized | Lower |

| Operational Mode | Continuous | Batch |

| Complexity & Cost | Higher | Lower & simpler |

| Ideal For | Fast pyrolysis, fine particles | Simpler, small-scale operations |

Ready to optimize your pyrolysis process and maximize bio-oil production?

At KINTEK, we specialize in advanced laboratory equipment, including pyrolysis reactors tailored to your specific feedstock and output goals. Whether you're processing biomass, plastics, or other organic wastes, our expertise ensures you get the efficient, high-yield results you need.

Contact us today via our [#ContactForm] to discuss how our solutions can enhance your lab's capabilities and drive your research forward.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas