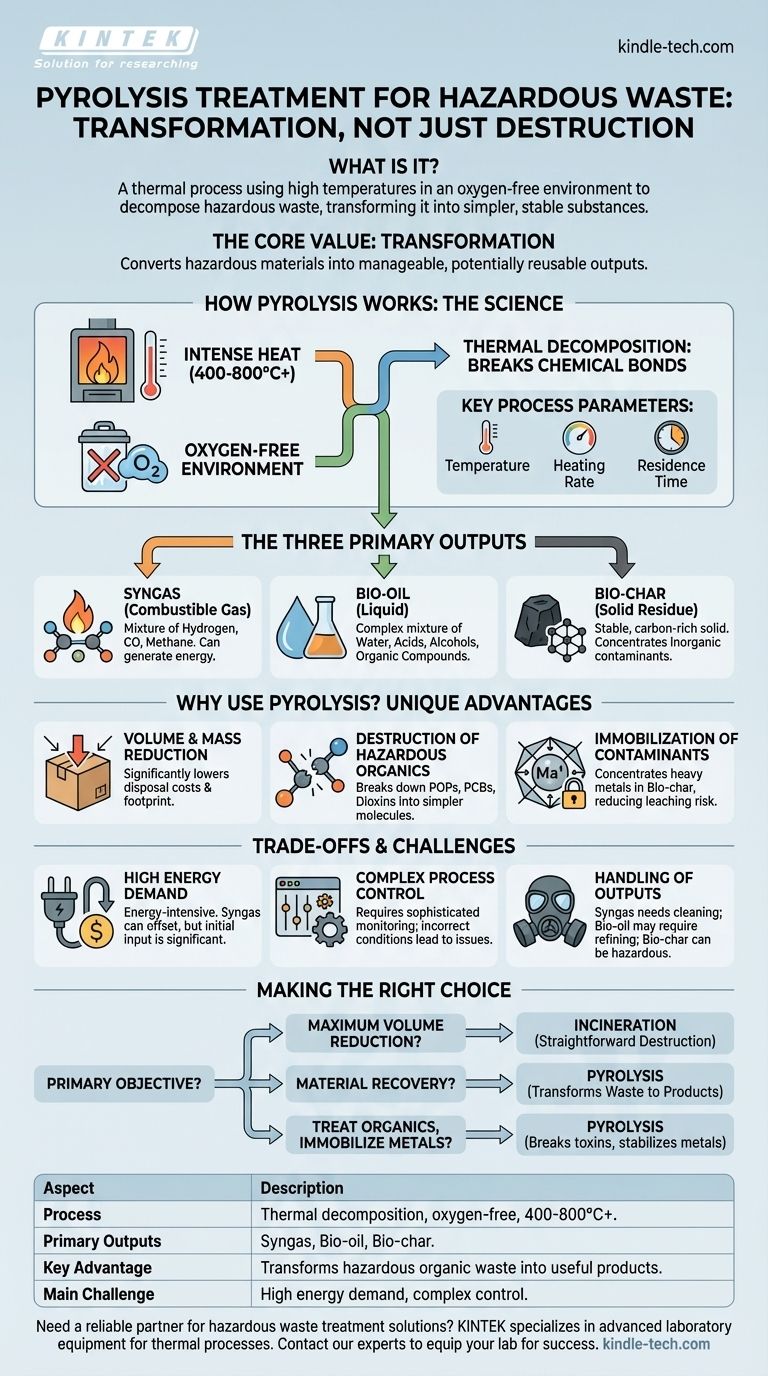

In essence, pyrolysis is a thermal treatment process that uses high temperatures in an oxygen-free environment to decompose hazardous waste. Unlike incineration, which burns waste, pyrolysis breaks down complex materials into simpler, more stable substances: a combustible gas (syngas), a liquid oil (bio-oil), and a solid, carbon-rich residue (bio-char). This method serves to both reduce waste volume and transform hazardous components into less harmful or even valuable forms.

The core value of pyrolysis is not just waste destruction, but waste transformation. It offers a sophisticated alternative to simple burning, aiming to convert hazardous materials into manageable and potentially reusable outputs, though this comes with significant operational complexity.

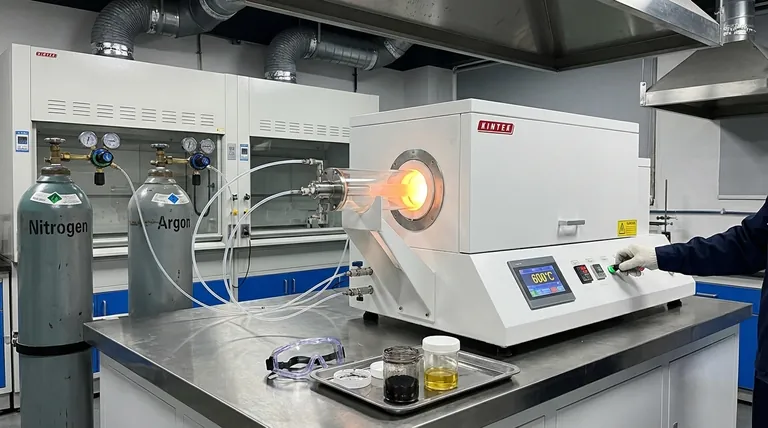

How Pyrolysis Works: The Science of Thermal Decomposition

Pyrolysis is fundamentally about chemical change driven by heat. By controlling the environment, we can dictate how hazardous materials break down.

The Core Principle: Heat Without Oxygen

The defining characteristic of pyrolysis is the absence of oxygen. When you heat organic materials with oxygen, they combust (burn). When you heat them without oxygen, they cannot burn. Instead, the intense heat (typically 400-800°C or higher) breaks the chemical bonds within the waste material, a process called thermal decomposition.

The Key Process Parameters

The outcome of pyrolysis is highly dependent on specific conditions. Operators must precisely control the temperature, the heating rate, and the residence time (how long the waste is kept at the target temperature). Small changes to these variables can significantly alter the proportions and quality of the gas, liquid, and solid outputs.

The Three Primary Outputs

The process separates the initial waste stream into three distinct product streams:

- Syngas: A mixture of combustible gases like hydrogen, carbon monoxide, and methane.

- Bio-oil (Pyrolysis Oil): A complex liquid mixture of water, acids, alcohols, and other organic compounds.

- Bio-char: A stable, carbon-rich solid residue.

Why Use Pyrolysis for Hazardous Waste?

While more complex than landfilling or incineration, pyrolysis offers unique advantages for specific types of hazardous waste, particularly those with high organic content.

Volume and Mass Reduction

Like other thermal treatments, pyrolysis dramatically reduces the volume of the original waste. This significantly lowers the costs and environmental footprint associated with final disposal in a specialized landfill.

Destruction of Hazardous Organics

The high temperatures effectively destroy a wide range of hazardous organic compounds. Persistent organic pollutants (POPs) like PCBs, dioxins, and pesticides are broken down into much simpler and less toxic molecules found in the syngas and bio-oil.

Immobilization of Contaminants

Pyrolysis does not destroy inorganic materials like heavy metals. Instead, it concentrates them in the solid bio-char. This process can transform the metals into more stable forms, locking them into the carbon matrix and reducing the risk of them leaching into the environment. The resulting char is much more stable and predictable than the original waste.

Understanding the Trade-offs and Challenges

Pyrolysis is a powerful tool, but it is not a universal solution. A clear-eyed assessment of its limitations is critical for effective application.

High Energy Demand

Reaching and maintaining the high temperatures required for pyrolysis is an energy-intensive process. While the syngas produced can be used to generate energy and offset some of this demand, the initial energy input remains a significant operational cost and consideration.

Complex Process Control

This is not a "set it and forget it" technology. The process requires sophisticated monitoring and control systems to manage temperature and feedstock consistency. Failure to maintain optimal conditions can lead to incomplete destruction of contaminants or the production of low-quality, difficult-to-manage outputs.

Handling of Outputs

The outputs of pyrolysis are not always immediately usable. The syngas may need to be cleaned ("scrubbed") to remove acid gases or other impurities before it can be used in an engine or turbine. The bio-oil can be corrosive and complex, often requiring further refining. Finally, the bio-char, while stable, may still be classified as hazardous waste due to the high concentration of heavy metals and require disposal in a secure landfill.

Making the Right Choice for Your Waste Stream

Choosing a thermal treatment technology depends entirely on your primary objective and the specific composition of your hazardous waste stream.

- If your primary focus is maximum volume reduction with established technology: Traditional incineration is often a more straightforward and widely understood option for destroying organic waste.

- If your primary focus is material recovery from organic waste: Pyrolysis is the superior choice, as it is designed to transform waste into distinct solid, liquid, and gas products for potential reuse.

- If your primary focus is treating organic contaminants while immobilizing heavy metals: Pyrolysis offers a key advantage by breaking down organic toxins while safely concentrating and stabilizing inorganic contaminants in the solid char.

Ultimately, selecting the right treatment method is a strategic decision that balances your environmental goals with operational and economic realities.

Summary Table:

| Aspect | Description |

|---|---|

| Process | Thermal decomposition in an oxygen-free environment (400-800°C+). |

| Primary Outputs | Syngas (combustible gas), Bio-oil (liquid), Bio-char (solid residue). |

| Key Advantage | Transforms hazardous organic waste into less harmful, potentially valuable products. |

| Main Challenge | High energy demand and complex process control requirements. |

Need a reliable partner for your hazardous waste treatment solutions? KINTEK specializes in advanced laboratory equipment and consumables for research and development in thermal processes like pyrolysis. Whether you are optimizing process parameters or analyzing output streams, our high-quality tools can support your goals for safe and efficient waste transformation. Contact our experts today to discuss how we can equip your lab for success.

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What are the equipment requirements for loading platinum (Pt) onto composite supports? Precise Stirring for High Dispersion

- What are the process advantages of using a rotary tube furnace for WS2 powder? Achieve Superior Material Crystallinity

- What is the difference between pyrolysis combustion and gasification? A Guide to Thermal Conversion Technologies

- What is the range of pyrolysis? Master Temperature Control for Optimal Bio-Product Yields

- How do high-temperature reaction furnaces control in-situ MMCs? Master Material Precision and Structural Integrity