At its core, DC (Direct Current) sputtering is a cost-effective technique used to deposit thin films of electrically conductive materials, such as metals. In contrast, RF (Radio Frequency) sputtering is a more versatile method capable of depositing non-conductive, or insulating, materials like ceramics by using an alternating current to overcome technical limitations inherent in the DC process.

The fundamental choice between DC and RF sputtering comes down to the electrical properties of your target material. DC sputtering works only for conductors, while RF sputtering works for both conductors and insulators, solving the critical issue of electrical charge buildup on the target's surface.

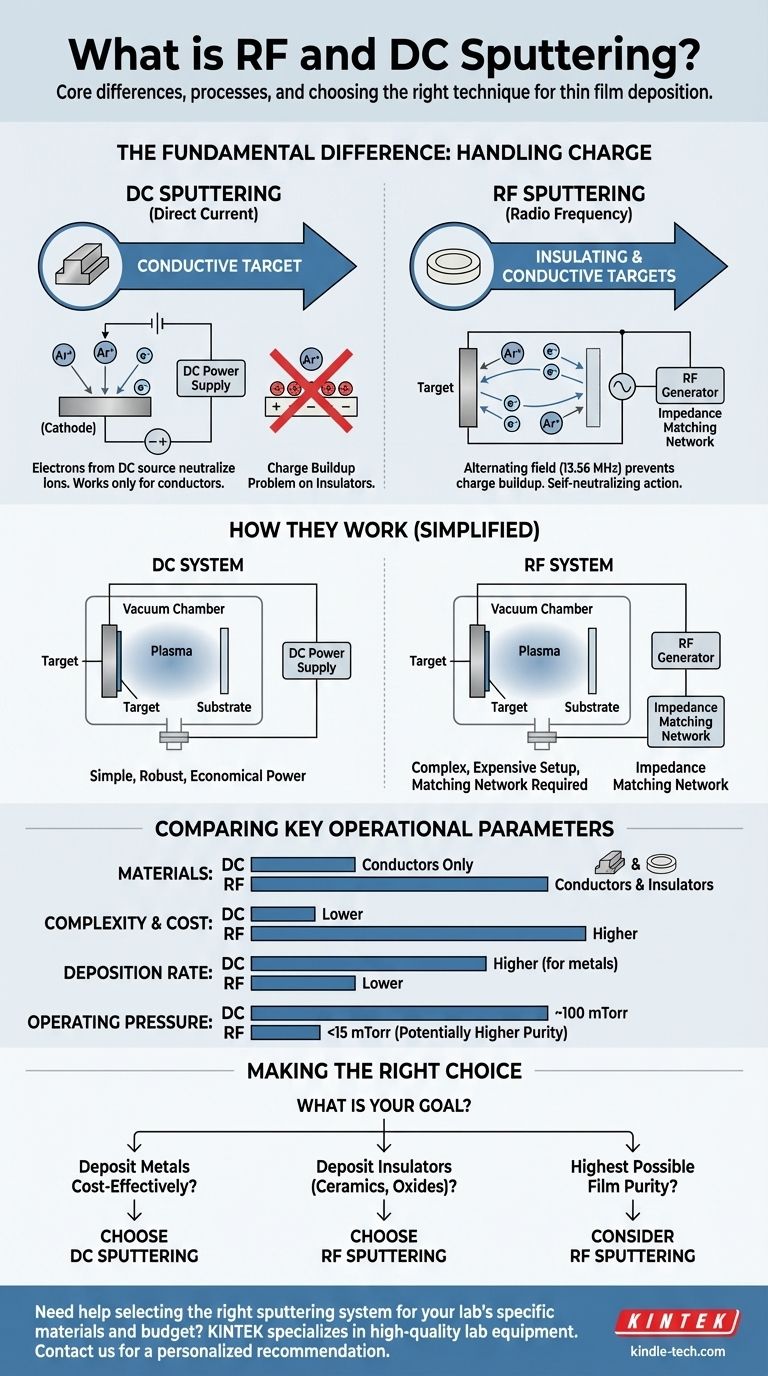

The Fundamental Difference: Handling Electrical Charge

The primary distinction between these two physical vapor deposition (PVD) techniques lies in how they energize the target material to be deposited. This is dictated by the target's ability to conduct electricity.

How DC Sputtering Works

In a DC sputtering system, a high DC voltage is applied to a vacuum chamber. The target material, which is the source of the film, acts as the cathode (negative electrode).

A gas, typically Argon, is introduced and ionized, creating a plasma of positive ions and electrons. These positive ions are accelerated toward the negatively charged target, striking it with enough force to dislodge, or "sputter," atoms.

This process works efficiently as long as the target is electrically conductive. The constant flow of electrons from the DC power supply neutralizes the positive ions arriving at the target, allowing the process to continue.

The Charge Buildup Problem

If you attempt to use a non-conductive (insulating) target with a DC source, a problem called "charge buildup" occurs.

Positive ions still strike the target, but because the material is an insulator, the positive charge cannot be neutralized. The target surface quickly becomes positively charged, repelling the very ions needed to continue the sputtering process and effectively halting deposition.

The RF Sputtering Solution

RF sputtering solves the charge buildup problem by replacing the DC power source with a high-frequency AC power source, typically fixed at 13.56 MHz. This is in the radio frequency range, hence the name.

The rapid alternation of the electric field means the target is alternately bombarded by positive ions and electrons during each cycle. The electron bombardment phase effectively neutralizes the positive charge that builds up during the ion bombardment phase.

This "self-neutralizing" action prevents charge buildup, allowing for the continuous, stable sputtering of insulating materials. A special impedance-matching network is required to efficiently transfer the RF power to the plasma, making the system more complex than a DC setup.

Comparing Key Operational Parameters

Beyond the type of material, RF and DC sputtering differ in several important operational aspects that influence film quality, cost, and efficiency.

Power Source and Complexity

A DC sputtering system uses a simple, robust, and economical high-voltage DC power supply.

An RF sputtering system requires a more complex and expensive setup, including an RF generator and an impedance-matching network to manage the power transfer to the plasma.

System Pressure

DC sputtering typically operates at higher pressures (e.g., around 100 mTorr) to maintain a stable plasma.

RF sputtering can sustain a plasma at much lower pressures (e.g., under 15 mTorr). This is advantageous because fewer gas atoms in the chamber mean sputtered atoms are less likely to collide on their way to the substrate, resulting in a more direct deposition path and potentially higher-purity films.

Deposition Rate

For metals, DC sputtering generally offers a higher deposition rate and is more efficient.

RF sputtering typically has a lower sputter yield and deposition rate compared to DC sputtering for the same material, partly due to the energy consumed in the alternating electron and ion bombardment cycles.

Understanding the Trade-offs

Choosing a sputtering technique involves balancing capability against complexity and cost. Neither method is universally superior; they are tools designed for different tasks.

The Limitation of DC Sputtering: Materials

The single greatest drawback of DC sputtering is its inability to deposit dielectric (insulating) materials. This makes it unsuitable for applications involving many common ceramics, oxides, and polymers.

The Drawbacks of RF Sputtering: Cost and Rate

The primary trade-off for RF sputtering's versatility is its increased cost and complexity. The RF power supply and matching network are significantly more expensive than their DC counterparts.

Furthermore, the generally lower deposition rates can increase process time, impacting throughput, especially in large-scale production environments.

Making the Right Choice for Your Application

Your decision should be directly guided by the material you need to deposit and your project's budget and performance requirements.

- If your primary focus is depositing metals or other conductive materials cost-effectively: DC sputtering is the clear and standard choice for its simplicity, high deposition rate, and economic efficiency.

- If your primary focus is depositing insulating materials like ceramics or oxides: RF sputtering is the necessary and effective solution, as DC sputtering is not a viable option.

- If your primary focus is achieving the highest possible film purity and density: RF sputtering may offer an advantage even for some metals, as it can operate at lower pressures, reducing gas incorporation into the film.

Ultimately, understanding the electrical nature of your target material is the key to selecting the correct sputtering technology for your goal.

Summary Table:

| Feature | DC Sputtering | RF Sputtering |

|---|---|---|

| Best For | Conductive materials (metals) | Insulating & conductive materials (ceramics, oxides) |

| Complexity & Cost | Lower | Higher (requires RF generator & matching network) |

| Deposition Rate | Higher | Lower |

| Operating Pressure | Higher (~100 mTorr) | Lower (<15 mTorr) |

| Key Advantage | Cost-effective for metals | Can deposit insulating materials |

Need help selecting the right sputtering system for your lab's specific materials and budget?

At KINTEK, we specialize in providing high-quality lab equipment, including sputtering systems tailored for both conductive and insulating materials. Our experts can help you choose the perfect solution to achieve precise, high-purity thin films for your research or production needs.

Contact us today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition