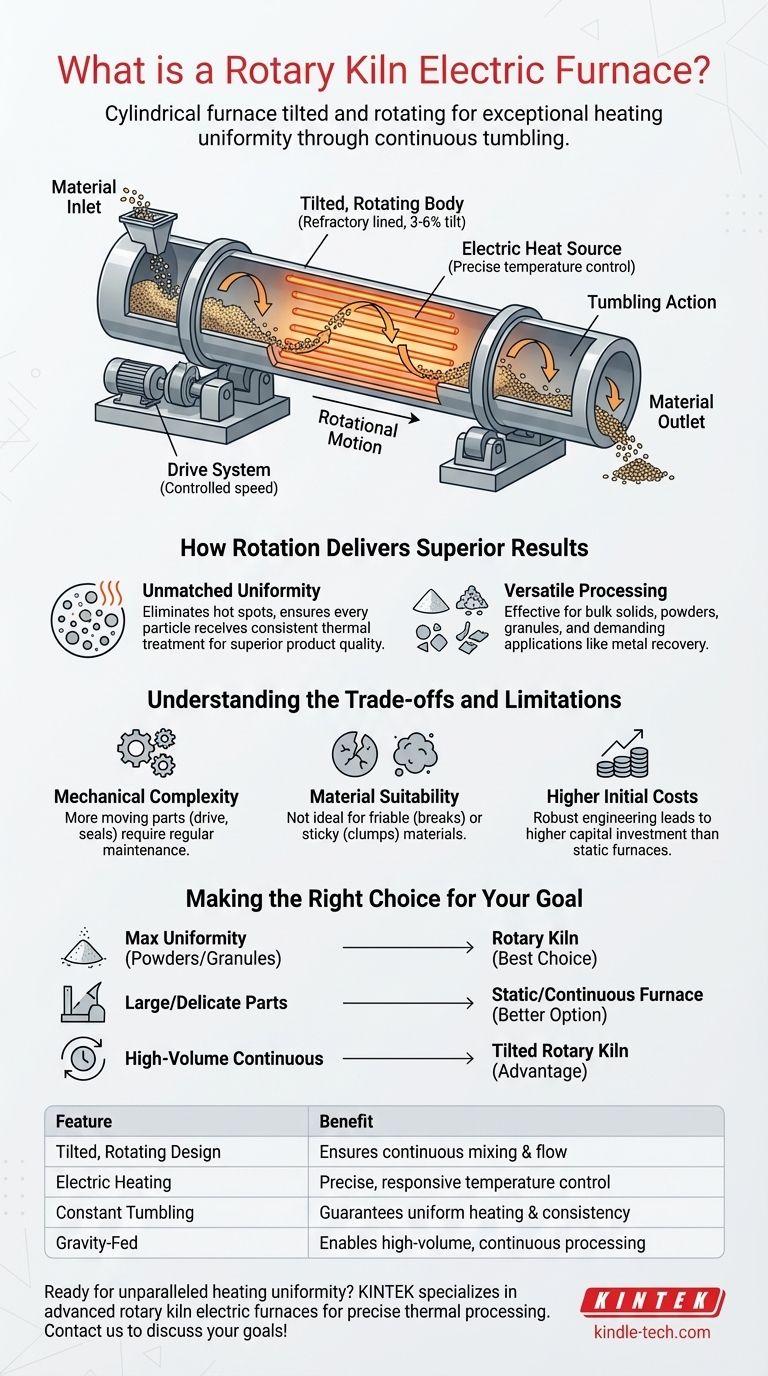

A rotary kiln electric furnace is a cylindrical industrial furnace that is tilted at a slight angle and rotates slowly around its axis. This design uses an internal electric heat source and the force of gravity to tumble, mix, and convey materials from one end to the other, ensuring they are heated with exceptional uniformity.

The essential purpose of a rotary kiln is not simply to heat material, but to achieve superior process consistency. Its constant rotation is the key, preventing hot spots and ensuring every particle receives the same thermal treatment as it moves through the furnace.

The Core Design Principles

A rotary kiln electric furnace operates on a few simple but powerful mechanical and thermal principles. Understanding its components reveals why it is so effective for specific applications.

The Tilted, Rotating Body

The main furnace is a long, barrel-shaped steel cylinder. This body is lined with refractory materials to withstand extreme internal temperatures and protect the outer steel shell.

The entire cylinder is mounted on support wheels and positioned at a slight inclination, typically between 3% and 6%.

The Drive System

A powerful electric motor connected to a gear or wheel system drives the furnace body. This system turns the entire cylinder at a slow, controlled speed.

This rotational motion is fundamental to the furnace's function.

The Material Flow

As the furnace rotates, the material inside is continuously lifted up the side of the cylinder and then tumbles back down.

Combined with the furnace's tilt, this tumbling action causes the material to gradually move from the higher entry point to the lower exit point, ensuring a continuous flow.

The Electric Heat Source

The term "electric furnace" specifies the heating method. Unlike fuel-fired kilns, it uses electrical elements to generate heat.

This allows for highly accurate and responsive temperature control, which can be managed by a computer system to maintain precise heating profiles for the material being processed.

How Rotation Delivers Superior Results

The unique design of a rotary kiln directly translates into significant processing advantages, particularly for bulk solids.

Unmatched Heating Uniformity

The primary benefit is uniform heating. In a static furnace, material at the bottom and center can remain cooler than the material at the edges.

The constant tumbling inside a rotary kiln ensures the material is thoroughly mixed. This action eliminates temperature gradients and guarantees every particle is exposed to the same heat, improving the quality and consistency of the final product.

Versatile Material Processing

This design is highly effective for a wide range of materials. It excels at processing powders, granules, and other bulk solids.

It is also used in demanding applications like metal recovery, where it can process scrap, battery paste, and various drosses by ensuring all components reach the necessary reaction temperatures.

Understanding the Trade-offs and Limitations

While powerful, the rotary kiln design is not a universal solution. Its specific characteristics present trade-offs that must be considered.

Mechanical Complexity

The drive systems, support wheels, and seals required for rotation introduce mechanical complexity. These moving parts require regular maintenance and are potential points of failure compared to simpler, static furnace designs.

Material Suitability

The tumbling action can be a disadvantage for certain materials. Friable or delicate products may break apart, creating unwanted dust or fines. Conversely, sticky materials may clump together, preventing uniform flow and heating.

Structural and Investment Costs

The robust engineering required to support and rotate a massive, heated cylinder can result in higher initial capital costs compared to static alternatives of a similar capacity.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the material you are processing and your desired outcome.

- If your primary focus is achieving the highest possible temperature uniformity for powders or granules: The mixing action of a rotary kiln is purpose-built for this and is likely your best choice.

- If your primary focus is processing large, solid parts or delicate materials that cannot be tumbled: A static batch furnace or a non-rotating continuous furnace would be a more suitable option.

- If your primary focus is high-volume, continuous processing of bulk solids: The gravity-fed, self-conveying nature of a tilted rotary kiln offers a distinct advantage for automated, around-the-clock operations.

By understanding its core principle of heating through motion, you can determine if a rotary kiln electric furnace is the optimal tool to achieve your specific material processing goals.

Summary Table:

| Feature | Benefit |

|---|---|

| Tilted, Rotating Design | Ensures continuous material mixing and flow |

| Electric Heating Elements | Provides precise, responsive temperature control |

| Constant Tumbling Action | Guarantees uniform heating and superior product consistency |

| Gravity-Fed Conveyance | Enables high-volume, continuous processing |

Ready to achieve unparalleled heating uniformity in your lab or production line? KINTEK specializes in advanced lab equipment, including rotary kiln electric furnaces designed for precise thermal processing of powders, granules, and bulk solids. Our solutions ensure consistent results, improved product quality, and efficient continuous operation. Contact us today to discuss how our expertise can meet your specific material processing goals!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the different types of bed motion in a rotary kiln? Optimize Mixing and Heat Transfer Efficiency

- How do rotary kilns work? A Guide to Industrial Heating & Material Processing

- What is the temperature of the pyrolysis reactor? The Key to Controlling Bio-Oil, Biochar, and Syngas Yields

- What are the advantages of catalytic pyrolysis over thermal pyrolysis? Achieve Higher-Quality Bio-Oil and Chemicals

- What is a common method used to regenerate spent activated carbon? Restore Your Carbon's Adsorption Power

- What role does a rotary kiln play in the incineration treatment of waste composite materials? Energy & Volume Solutions

- What is the temperature zone in a rotary kiln? Master the Thermal Profile for Optimal Processing

- What is the function of a rotary kiln? A Guide to Industrial Thermal Processing