In the context of pyrolysis, safety is the comprehensive system of procedures, equipment design, and operator protocols required to manage the extreme risks of thermochemically decomposing materials. It involves controlling high temperatures and safely handling the resulting flammable and potentially explosive gases and liquids. Total safety is a discipline covering three core areas: process safety, equipment safety, and human safety.

The fundamental safety challenge in pyrolysis is not just managing high heat, but preventing the uncontrolled release and ignition of the volatile, flammable compounds that are the intended products of the process.

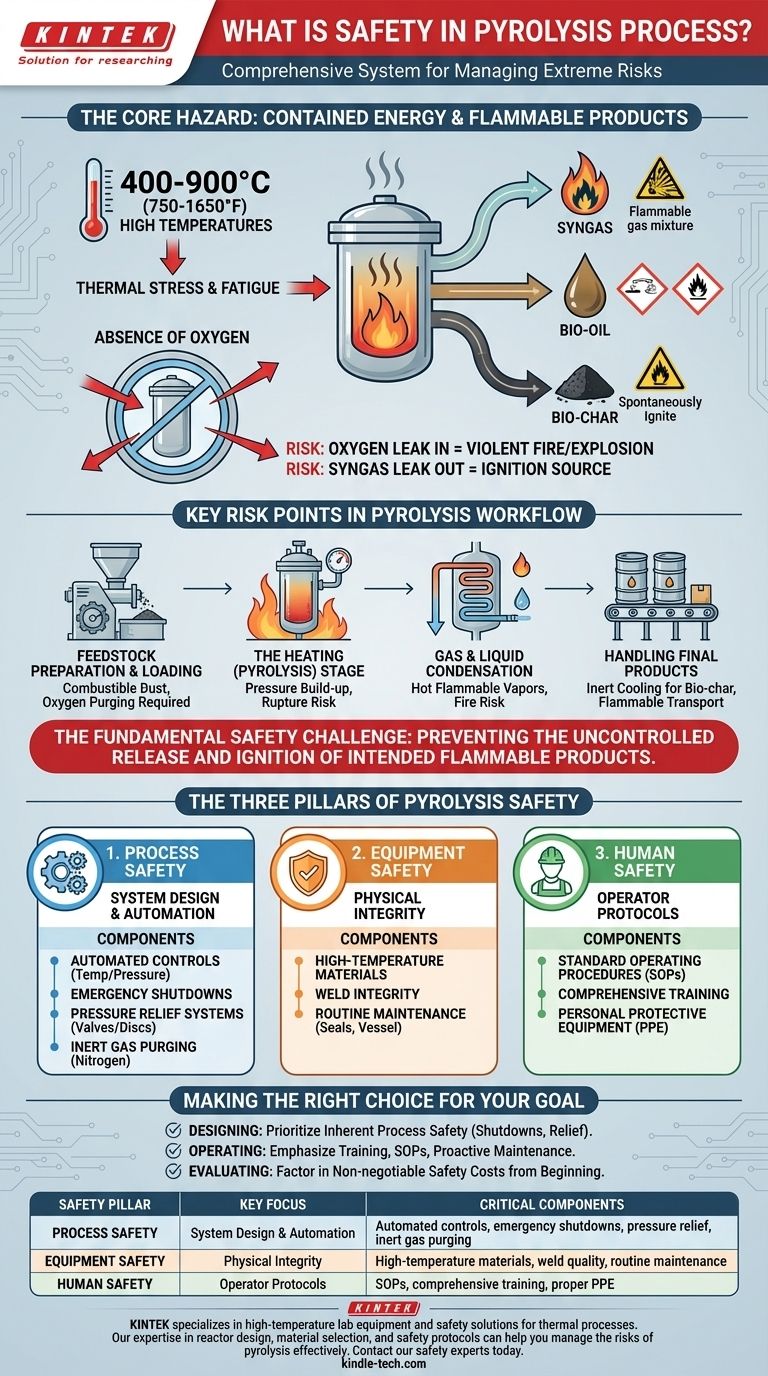

The Core Hazard: Contained Energy and Flammable Products

Understanding pyrolysis safety begins with recognizing the inherent risks of the process itself. You are deliberately creating flammable materials inside a high-temperature, sealed environment.

High Temperatures and Thermal Stress

The process operates at temperatures between 400-900°C (750-1650°F). This extreme heat places significant thermal stress on the reactor vessel, seals, and associated piping, creating a constant risk of material fatigue or failure.

Production of Flammable Byproducts

The primary outputs of pyrolysis are themselves hazardous.

- Syngas: A mixture of flammable gases like hydrogen, methane, and carbon monoxide. A leak can quickly create an explosive atmosphere.

- Bio-oil: A liquid fuel that is flammable and can have corrosive properties.

- Bio-char: The solid residue, which can be pyrophoric, meaning it can spontaneously ignite when exposed to oxygen, especially when hot.

The Critical "Absence of Oxygen"

Pyrolysis works by heating material without oxygen to prevent combustion. While this makes the process inside the reactor stable, it creates a significant hazard at every seal and joint. If air (oxygen) leaks into the hot reactor, it can cause a violent fire or explosion. Conversely, if flammable syngas leaks out of the reactor into the surrounding air, it can easily find an ignition source.

Key Risk Points in the Pyrolysis Workflow

Safety must be considered at every step, as each stage presents unique challenges.

Feedstock Preparation and Loading

Handling raw materials can introduce risks. Grinding dry biomass can create combustible dust, and loading the material requires a reliable method for purging oxygen from the system before heating begins.

The Heating (Pyrolysis) Stage

This is the most critical phase. As the material decomposes, it generates a large volume of gas, causing pressure to build inside the reactor. Without robust pressure monitoring and relief systems, the vessel can rupture catastrophically.

Gas and Liquid Condensation

The hot vapor stream must be cooled to condense the bio-oil. This part of the system involves handling hot, flammable vapors under pressure. Any leaks in the condensation train are a primary fire risk.

Handling Final Products

Once the process is complete, the products must be removed and stored safely. Hot bio-char must be cooled in an inert environment to prevent self-ignition, and the flammable syngas and bio-oil must be transferred to appropriate storage or utilization systems.

The Three Pillars of Pyrolysis Safety

A robust safety strategy is built on three interconnected principles. Neglecting any one of them undermines the entire operation.

1. Process Safety

This concerns the fundamental design and engineering of the system. It is the first and most important line of defense.

- Automated Controls: Reliable sensors for temperature and pressure are non-negotiable.

- Emergency Shutdowns: An automated system that can safely shut down the process if parameters go outside of safe limits.

- Pressure Relief Systems: Properly sized safety valves and rupture discs that prevent over-pressurization.

- Inert Gas Purging: Using an inert gas like nitrogen to remove all oxygen before startup and to safely cool the system after shutdown.

2. Equipment Safety

This focuses on the physical integrity of the machinery itself.

- Material Selection: The reactor and components must be made from materials that can withstand high temperatures and potentially corrosive compounds.

- Weld Integrity: All welds must be of the highest quality, as they are often the weakest points in a pressurized system.

- Routine Maintenance: Regular inspection and testing of seals, valves, and vessel thickness are critical to catch potential failures before they happen.

3. Human Safety

Even the best-designed system can be defeated by human error.

- Standard Operating Procedures (SOPs): Clear, written instructions for every phase of operation, including startup, shutdown, and emergencies.

- Comprehensive Training: Operators must understand not just the "how" but the "why" behind safety procedures.

- Personal Protective Equipment (PPE): Appropriate PPE, such as heat-resistant clothing and respirators, must be used when interacting with the system.

Making the Right Choice for Your Goal

Your approach to safety will depend on your role in the pyrolysis value chain.

- If your primary focus is designing or selecting a system: Prioritize inherent process safety features like automated shutdowns and robust pressure relief engineering.

- If your primary focus is operating an existing facility: Emphasize rigorous training, strict adherence to SOPs, and a proactive maintenance schedule to ensure equipment integrity.

- If your primary focus is evaluating the viability of pyrolysis: Factor in the significant, non-negotiable costs of building and maintaining a safe system from the very beginning.

Ultimately, safety in pyrolysis is not an optional feature; it is the fundamental prerequisite for a successful and sustainable operation.

Summary Table:

| Safety Pillar | Key Focus | Critical Components |

|---|---|---|

| Process Safety | System Design & Automation | Automated controls, emergency shutdowns, pressure relief, inert gas purging |

| Equipment Safety | Physical Integrity | High-temperature materials, weld quality, routine maintenance |

| Human Safety | Operator Protocols | SOPs, comprehensive training, proper PPE |

Ensure your pyrolysis operation is built on a foundation of safety. KINTEK specializes in high-temperature lab equipment and safety solutions for thermal processes. Our expertise in reactor design, material selection, and safety protocols can help you manage the risks of pyrolysis effectively. Contact our safety experts today to discuss how we can support your project with reliable, safety-first equipment and consumables.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is refractory in rotary kiln? A Guide to Protecting Your Kiln and Maximizing Efficiency

- What is the product composition of pyrolysis? Unlock the Potential of Biochar, Bio-Oil, and Syngas

- What happens in a calciner? A Deep Dive into Industrial Thermal Transformation

- What is the end product of pyrolysis? Transform Waste into Biochar, Bio-oil, and Syngas

- What is the purpose of plastic pyrolysis? Convert Waste Plastic into Valuable Resources