At its core, a sintered material is a solid object created by taking a fine powder, compressing it into a desired shape, and heating it to a high temperature just below its melting point. This process causes the individual powder particles to bond and fuse together, transforming the loose compact into a strong, dense, and functional component without ever becoming a liquid.

Sintering is a manufacturing technology that transforms powdered materials into a solid mass using heat and pressure. It excels at creating components from materials with extremely high melting points or unique composite blends that are difficult or impossible to make through traditional melting and casting.

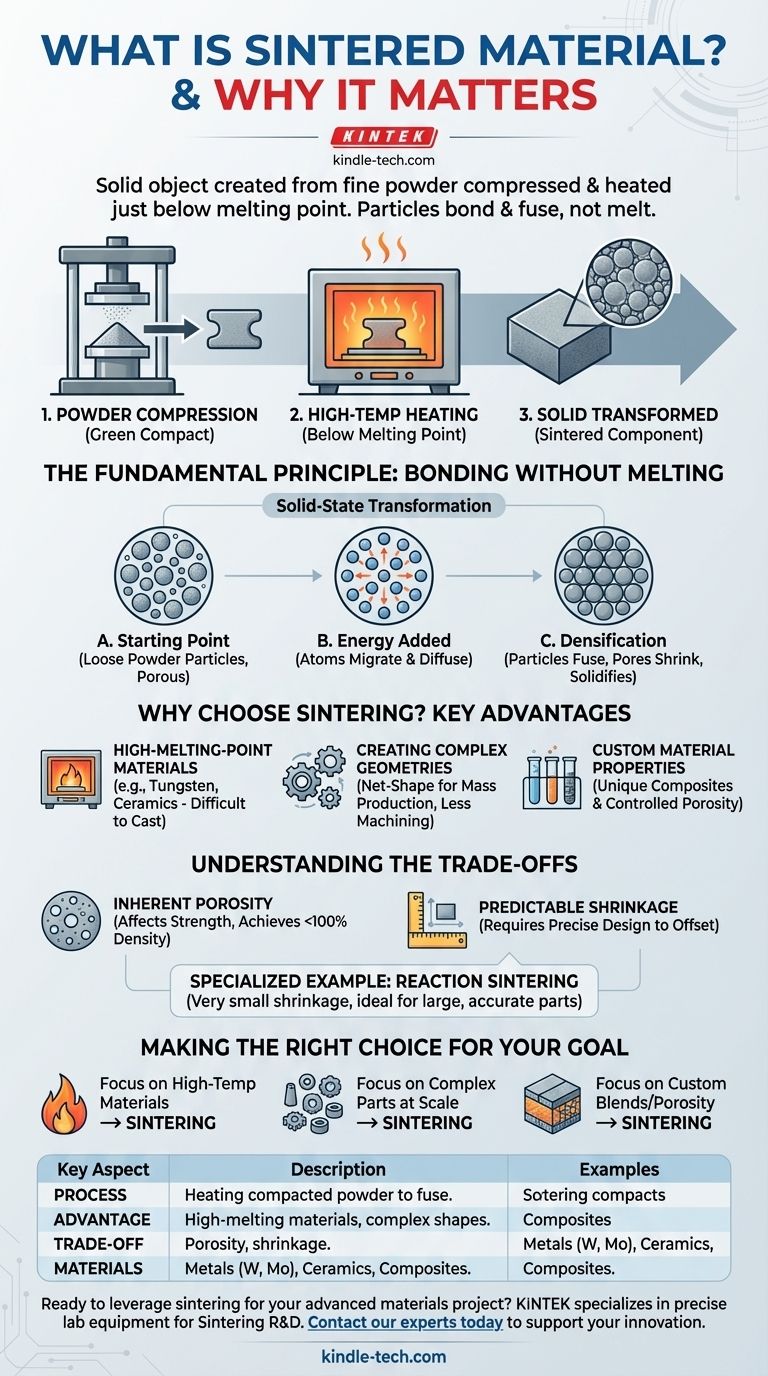

The Fundamental Principle: Bonding Without Melting

Sintering is a fascinating process of solid-state transformation. It’s not about melting and resolidifying; it's about encouraging atoms to move and bond while the material remains fundamentally solid.

The Starting Point: A Compacted Powder

The process begins with a fine powder of a metal, ceramic, or composite material. This powder is placed in a die and compressed under high pressure to form a fragile part known as a "green compact." This initial shape is porous and has very little mechanical strength.

The Role of High-Temperature Energy

The green compact is then placed in a furnace and heated to a precisely controlled temperature, typically around 70-90% of the material's absolute melting point. This intense heat provides the thermal energy that activates the atoms within the particles.

The Transformation: From Powder to Solid

With this added energy, atoms begin to migrate across the boundaries where individual particles touch. This atomic diffusion causes the necks between particles to grow, eliminating the pores and pulling the particles closer together. The result is a significant increase in density, strength, and hardness as the object shrinks and solidifies.

Why Choose Sintering? Key Advantages

Engineers and manufacturers choose sintering when conventional methods fall short. The process offers several distinct and powerful advantages that unlock new design possibilities.

High-Melting-Point Materials

Sintering is one of the few viable methods for shaping materials with exceptionally high melting points, such as tungsten, molybdenum, and advanced ceramics. Trying to melt and cast these materials is often impractical or technologically prohibitive.

Creating Complex Geometries

Because the process starts with a moldable powder, sintering is excellent for mass-producing small, intricate parts with high precision. This "net-shape" or "near-net-shape" capability drastically reduces the need for expensive and wasteful secondary machining.

Custom Material Properties

Sintering allows for the creation of unique materials. You can mix different types of powders—such as metals and ceramics—to create composites with specific properties like high heat resistance and excellent conductivity. It also allows for precise control over the final part's porosity, which is essential for applications like filters or self-lubricating bearings.

Understanding the Trade-offs

No process is perfect, and sintering has specific limitations that must be considered for any application. Acknowledging these trade-offs is key to making an informed decision.

Inherent Porosity

While the goal is densification, achieving 100% density is often difficult. Most sintered parts retain some residual porosity, which can impact properties like ultimate tensile strength and fracture toughness compared to a fully wrought or cast equivalent.

Predictable Shrinkage

As the pores are eliminated during the heating process, the entire component shrinks. This shrinkage must be precisely calculated and controlled in the initial design of the green compact to ensure the final part meets dimensional specifications.

A Specialized Example: Reaction Sintering

Certain variations of the process are designed to overcome these limitations. Reaction sintering, for example, is a method used for materials like silicon carbide. It is valued for its lower production cost and, critically, for exhibiting very small shrinkage. This makes it ideal for producing large or complex structures where dimensional accuracy is paramount, such as parts for high-temperature kilns or precision optical mirrors.

Making the Right Choice for Your Goal

Selecting sintering depends entirely on the material requirements and design intent of your project.

- If your primary focus is working with high-temperature materials: Sintering is the go-to process for shaping materials like tungsten and advanced ceramics that cannot be easily melted.

- If your primary focus is producing complex parts at scale: The ability to press powder into intricate shapes makes sintering highly efficient for mass production, minimizing waste and machining costs.

- If your primary focus is achieving custom material blends or controlled porosity: Sintering provides unique control over a material's final composition and density, enabling the creation of advanced composites and functional porous parts.

Ultimately, understanding the principles of sintering empowers you to select a manufacturing process that achieves material properties far beyond the limits of conventional methods.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Heating compacted powder below its melting point to fuse particles. |

| Primary Advantage | Shapes high-melting-point materials and complex geometries. |

| Key Trade-off | Inherent porosity and predictable shrinkage must be managed. |

| Common Materials | Metals (tungsten, molybdenum), Ceramics, Composites. |

Ready to leverage sintering for your advanced materials project?

KINTEK specializes in the precise lab equipment and consumables needed for sintering R&D and quality control. Whether you're developing new metal-ceramic composites or optimizing sintering cycles, our solutions help you achieve superior density and performance.

Contact our experts today to discuss how we can support your laboratory's sintering innovation.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What are the challenges of biomass production? Overcoming High Costs, Logistics, and Sustainability

- What are advantages of biomass energy conversion? Turn Waste into Renewable Power & Economic Growth

- Why KBr is used in FTIR system? The Key to Accurate Mid-IR Spectral Analysis

- What are the advantages of annealing process? Restore Workability and Stability in Your Materials

- What are the disadvantages of KBr FTIR? Key Limitations That Impact Your Data Quality

- What are the steps in additive manufacturing process? A Complete Guide to the Digital-to-Physical Workflow

- How efficient is plastic pyrolysis? Maximizing Waste-to-Energy Conversion

- What is sputtering target material? The Blueprint for High-Quality Thin Film Coatings