Spark Plasma Sintering (SPS) is an advanced manufacturing technique used to rapidly consolidate polymer powders into a dense, solid material. Unlike conventional methods that rely on slow external heating in a furnace, SPS uses a combination of pulsed direct electrical current and uniaxial pressure to bond the polymer particles together in a matter of minutes.

The core advantage of SPS for polymers is its exceptional speed. This rapid processing minimizes the material's exposure to high temperatures, preventing the thermal degradation that often plagues conventional methods and enabling the creation of high-performance polymer composites with sensitive additives.

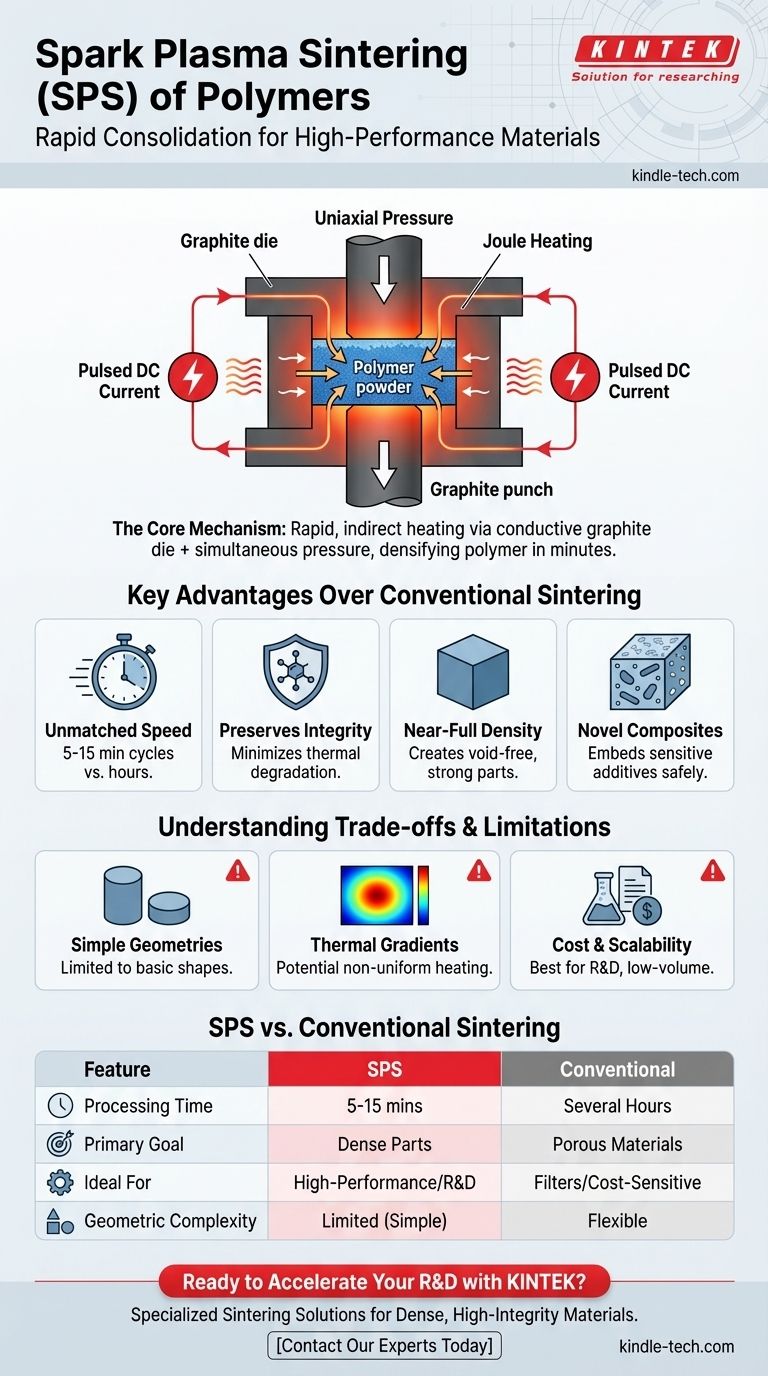

The Core Mechanism: How SPS Works with Polymers

While the name suggests a direct role for plasma, the primary mechanisms in polymer sintering are well-understood thermal and mechanical processes. The "spark plasma" term is a known misnomer; the key is rapid, localized heating.

The Role of Pulsed Current and Joule Heating

The polymer powder is loaded into a graphite die. A powerful, pulsed direct current (DC) is passed through this graphite tooling, not directly through the insulating polymer.

The graphite, being electrically resistive, heats up extremely quickly due to Joule heating. This heat is then rapidly conducted into the polymer powder, raising its temperature to the sintering point.

The Impact of Uniaxial Pressure

Simultaneously with the heating, a significant amount of uniaxial pressure is applied to the powder via graphite punches.

This pressure forces the softened polymer particles into intimate contact, aiding in plastic deformation and eliminating the voids between them. The synergy of rapid heating and pressure is what drives the rapid densification.

Overcoming the Insulator Challenge

Polymers are typically electrical insulators, so the pulsed current cannot flow through them effectively. SPS overcomes this by using the conductive graphite die as the primary heating element.

This indirect heating is incredibly efficient, ensuring the polymer reaches its processing temperature far faster than in a conventional oven, where heat must slowly radiate and convect inward.

Key Advantages Over Conventional Sintering

The unique mechanism of SPS provides distinct advantages over traditional polymer processing, which is often used to create porous materials like filters from polyethylene or polypropylene.

Unmatched Speed

An SPS cycle is typically completed in 5 to 15 minutes. This is a dramatic reduction compared to conventional hot pressing or furnace sintering, which can take many hours.

Preserving Polymer Integrity

The short duration at high temperatures is the most critical benefit. It minimizes thermal degradation, such as chain scission or oxidation, which can destroy a polymer's mechanical properties. This allows for the processing of thermally sensitive polymers.

Achieving Near-Full Density

The combination of pressure and heat efficiently eliminates porosity. While conventional sintering is often used to create intentionally porous structures, SPS excels at producing fully dense, void-free parts with superior mechanical strength.

Enabling Novel Composites

SPS is exceptionally well-suited for creating polymer matrix composites. Sensitive functional fillers, such as carbon nanotubes, graphene, or even biological molecules, can be embedded in the polymer matrix without being damaged by prolonged heat exposure.

Understanding the Trade-offs and Limitations

Despite its advantages, SPS is a specialized technique with specific constraints that make it unsuitable for all applications.

Geometric Constraints

The process is limited to simple geometries, such as discs, cylinders, and rectangular blocks. The reliance on a rigid die and uniaxial pressure prevents the creation of complex shapes.

Potential for Thermal Gradients

In larger samples or materials with very low thermal conductivity, non-uniform heating can occur. The outside of the sample may be hotter than the center, potentially leading to variations in density and mechanical properties.

Equipment Cost and Scalability

SPS systems are expensive and complex. This makes the technology best suited for research, development, and low-volume production of high-value components rather than mass manufacturing.

Choosing the Right Sintering Approach

Your choice of technology must be aligned with the properties you need in the final product.

- If your primary focus is creating porous materials for filtration or diffusion: Conventional sintering of large polymer particles remains the most effective and economical method.

- If your primary focus is rapidly prototyping dense, high-performance polymer parts: Spark Plasma Sintering offers an unmatched combination of speed and property preservation.

- If your primary focus is developing advanced composites with thermally sensitive additives: SPS is arguably the superior technique for embedding functional fillers without damaging them or the polymer matrix.

Ultimately, selecting the right technique depends on whether your end goal is simple, cost-effective porosity or advanced, high-density material performance.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Conventional Sintering |

|---|---|---|

| Processing Time | 5 - 15 minutes | Several hours |

| Primary Advantage | Minimizes thermal degradation; creates dense parts | Cost-effective for creating porous materials |

| Ideal For | High-performance parts, sensitive composites, R&D | Filters, porous structures, cost-sensitive production |

| Geometric Complexity | Limited (discs, cylinders) | More flexible |

Ready to rapidly prototype high-performance polymer parts or advanced composites?

KINTEK specializes in advanced lab equipment, including sintering solutions. Our expertise can help you leverage Spark Plasma Sintering to create dense, high-integrity materials with sensitive additives, all while dramatically reducing processing times.

Contact our experts today to discuss how SPS can accelerate your R&D and material development.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How does a vacuum hot press furnace ensure a robust metal skeleton in CuAlMn alloys? Master Sintering Precision

- How does pressure in vacuum hot-pressing affect Cu-2Ni-7Sn/45 steel? Achieve High-Strength Metallurgical Bonds

- What are the advantages of using a vacuum hot pressing furnace? Achieve Superior Density in Cu-Y Composites

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C

- What is the function of Hot Pressing equipment in TlBr material preparation? Achieve High-Resolution Semiconductors

- How does a vacuum hot press sintering furnace contribute to Al0.6CoCrFeNi/5052Al? Achieve 100% Dense Composites

- How does a vacuum hot press sintering furnace facilitate a high-quality bond? Achieve Superior Metallurgical Coating

- How does a vacuum hot pressing sintering furnace facilitate the high densification of Al-30%Sc alloys?