At its core, Spark Plasma Sintering (SPS) is an advanced powder consolidation technique that uses a combination of high-amperage pulsed direct current (DC) and uniaxial pressure to transform powders into dense solids. Also known as the Field-Assisted Sintering Technique (FAST), it achieves this with extraordinary speed and at significantly lower temperatures than conventional methods, fundamentally changing how advanced materials are created.

The critical insight is that SPS is not just about heating. It uses electrical current to simultaneously generate intense, uniform heat and create a plasma effect that cleans particle surfaces, allowing for dramatically faster and more effective bonding of materials.

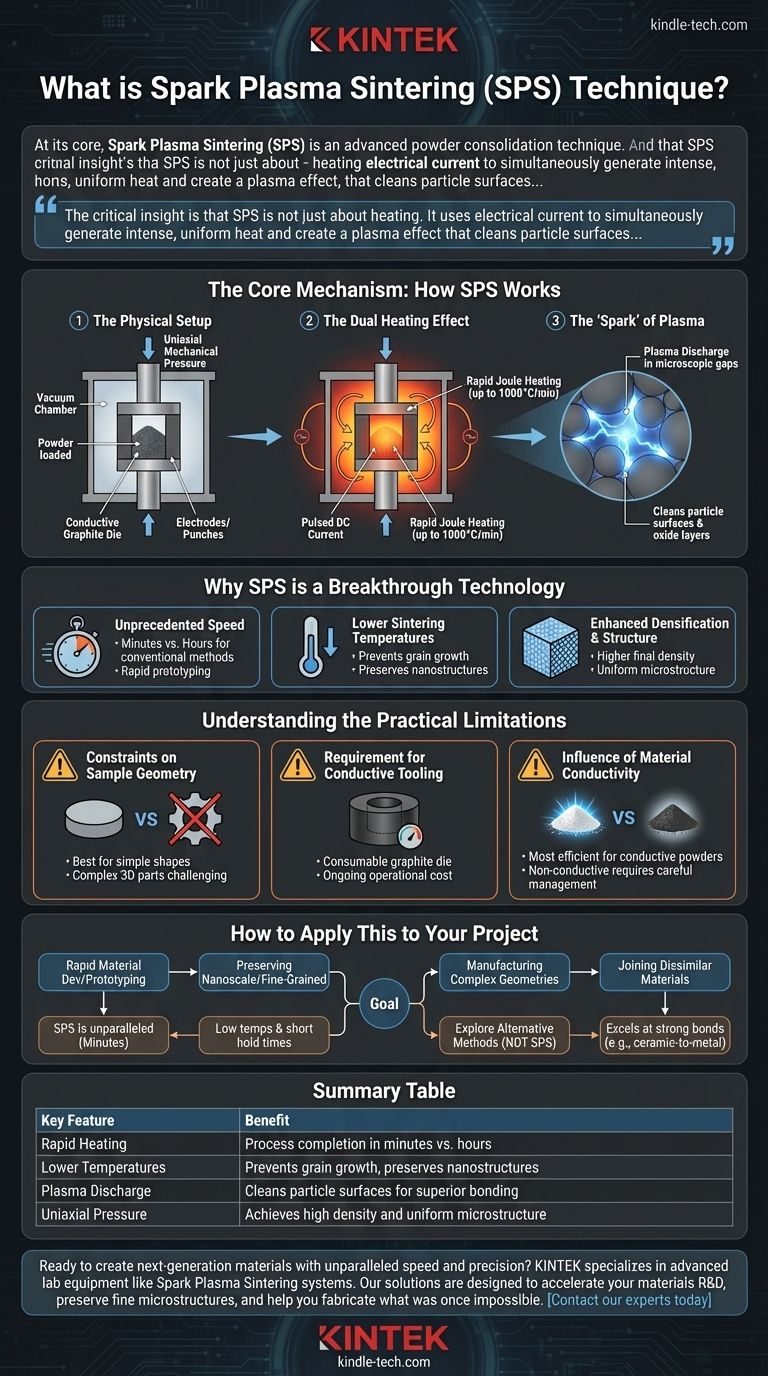

The Core Mechanism: How SPS Works

To understand the power of SPS, we must look beyond simple heating and see it as an integrated system of pressure, electricity, and thermal energy.

The Physical Setup

The process begins by loading a powder sample into a conductive die, typically made of graphite. This die assembly is then placed between two electrodes inside a vacuum chamber. A hydraulic system applies uniaxial mechanical pressure to the powder via the electrodes, which also act as punches.

The Dual Heating Effect

Unlike a conventional furnace that heats externally via radiation, SPS passes a pulsed DC current directly through the conductive graphite die and, if the material is conductive, through the powder itself. This creates rapid Joule heating from both the outside (the die) and the inside (the powder), resulting in incredibly fast and uniform temperature increases, often up to 1000°C per minute.

The "Spark" of Plasma

The pulsed current generates a unique phenomenon between the individual powder particles. The strong electric field can cause a plasma discharge in the microscopic gaps between particles. This momentary spark of plasma is energetic enough to strip away surface contaminants and oxide layers that normally inhibit bonding, effectively "scrubbing" the particles clean just before they are pressed together.

Why SPS is a Breakthrough Technology

The unique mechanism of SPS provides several key advantages that make it indispensable for advanced materials science and engineering.

Unprecedented Speed

By combining rapid heating with efficient particle bonding, the entire sintering process can be completed in a matter of minutes, compared to the many hours required for conventional furnace sintering. This allows for rapid prototyping and accelerates materials research.

Lower Sintering Temperatures

Because the plasma effect enhances bonding so effectively, densification can be achieved at temperatures several hundred degrees lower than in traditional methods. This is crucial for preventing unwanted grain growth, preserving the fine-grained or nanostructured properties that give many advanced materials their exceptional strength and performance.

Enhanced Densification and Structure

The combination of pressure, rapid heating, and clean particle surfaces results in materials with higher final density and a more uniform microstructure. This technique is especially effective for consolidating materials that are notoriously difficult to sinter, such as refractory metals and advanced ceramics.

Understanding the Practical Limitations

While powerful, SPS is not a universal solution. Its unique process introduces specific trade-offs that are critical to understand.

Constraints on Sample Geometry

The use of a rigid die and uniaxial pressure means SPS is best suited for producing simple shapes like discs, cylinders, and rectangular bars. Creating complex, three-dimensional parts is extremely challenging with this method.

Requirement for Conductive Tooling

The entire process relies on the graphite die and punches being electrically conductive. These components are consumables that degrade over time, representing an ongoing operational cost.

Influence of Material Conductivity

The process is most efficient when the powder itself is electrically conductive, as it benefits from direct internal heating. While non-conductive powders like many ceramics can be sintered successfully (relying solely on heat transferred from the graphite die), the heating dynamics are different and must be carefully managed.

How to Apply This to Your Project

SPS is a specialized tool. Choosing it depends entirely on your end goal.

- If your primary focus is rapid material development or prototyping: SPS is an unparalleled tool, capable of producing dense samples from novel powders in minutes.

- If your primary focus is preserving nanoscale or fine-grained microstructures: The low sintering temperatures and short hold times of SPS are its greatest strengths for creating high-performance materials.

- If your primary focus is manufacturing materials with complex geometries: You should explore alternative methods like metal injection molding or additive manufacturing, as SPS is poorly suited for this task.

- If your primary focus is joining dissimilar materials: SPS excels at creating strong bonds between different material classes, such as ceramic-to-metal, with minimal thermal damage.

Ultimately, Spark Plasma Sintering empowers engineers and scientists to create next-generation materials that were previously impossible to fabricate efficiently.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Rapid Heating | Process completion in minutes vs. hours |

| Lower Temperatures | Prevents grain growth, preserves nanostructures |

| Plasma Discharge | Cleans particle surfaces for superior bonding |

| Uniaxial Pressure | Achieves high density and uniform microstructure |

Ready to create next-generation materials with unparalleled speed and precision? KINTEK specializes in advanced lab equipment like Spark Plasma Sintering systems. Our solutions are designed to accelerate your materials R&D, preserve fine microstructures, and help you fabricate what was once impossible. Contact our experts today to discuss how we can empower your laboratory's innovation.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Three-dimensional electromagnetic sieving instrument

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What are the advantages of a vacuum hot pressing furnace? Achieve Superior Lithium Niobate Piezoelectric Density

- What is the difference between conventional and spark sintering? Choose the Right Process for Your Materials

- What are the advantages of using a vacuum hot-pressing furnace? Superior Copper-Graphite Composite Production

- What are the advantages of using vacuum hot press sintering for Fe3Si? Achieve Superior Density and Hardness

- What is the function of a vacuum hot pressing furnace (VHP)? Master Ti/Ti-Al Composite Fabrication

- What is the hot pressing method? A Guide to Efficient, High-Density Material Processing

- What role does a high-purity graphite mold play during hot pressing? Optimize Boron Carbide Sintering at 1850°C

- What role does the hot pressing process play in the fabrication of TlBr crystals? Achieve High-Performance Densification