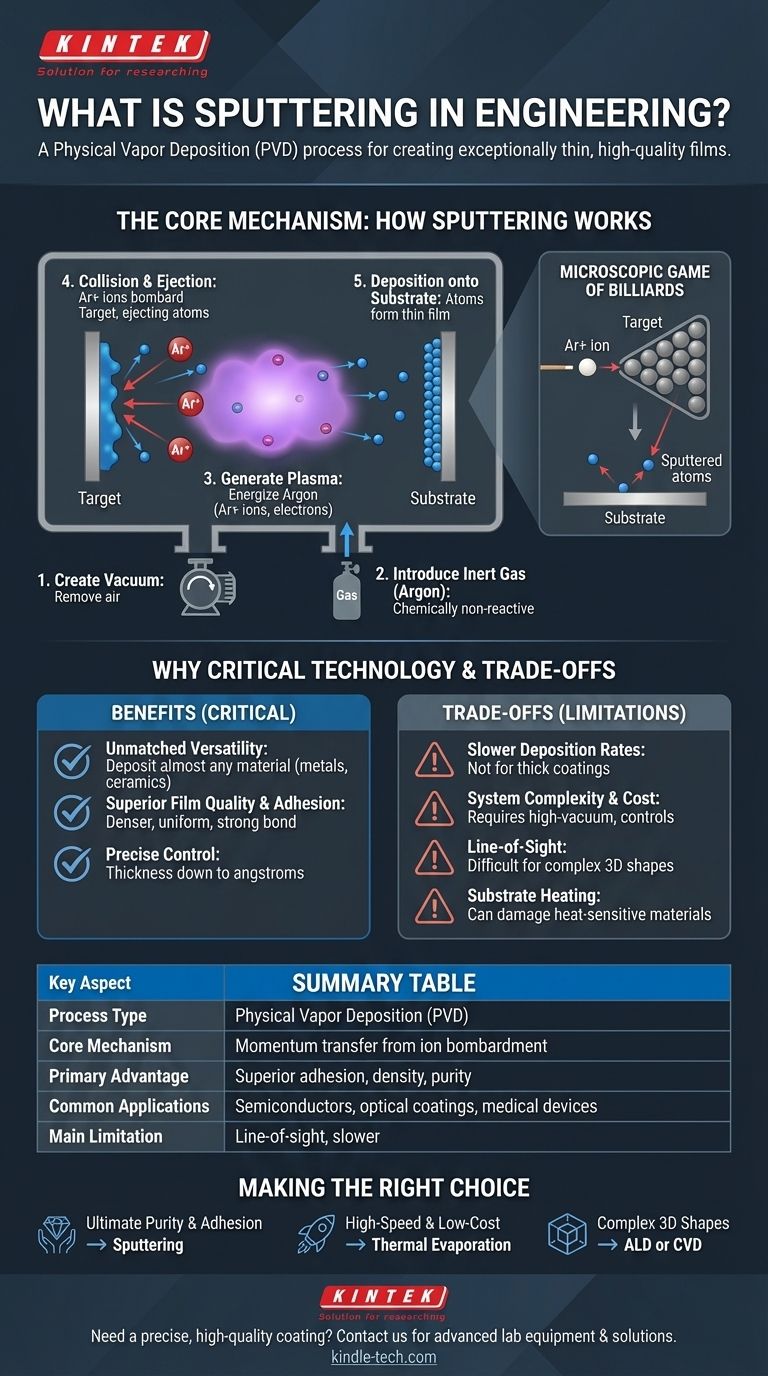

In engineering, sputtering is a physical vapor deposition (PVD) process used to create exceptionally thin, high-quality films of material onto a surface. It operates by ejecting atoms from a source material, known as a "target," by bombarding it with high-energy ions inside a vacuum. These ejected atoms then travel and deposit onto a nearby object, the "substrate," forming a uniform coating.

Sputtering is not a chemical reaction or a melting process; it is a physical momentum transfer. Think of it as a microscopic game of billiards where energetic ions are the cue ball, striking a rack of atoms (the target), and knocking some of them loose to coat a nearby surface.

The Core Mechanism: How Sputtering Works

Sputtering is a highly controlled process that takes place within a sealed vacuum chamber. The fundamental steps are consistent regardless of the specific material being deposited.

Step 1: Creating a Vacuum

First, nearly all air is pumped out of the chamber to create a vacuum. This is critical to prevent the sputtered atoms from colliding with air molecules and to avoid contamination of the final film.

Step 2: Introducing an Inert Gas

A small, controlled amount of an inert gas, most commonly Argon (Ar), is then introduced into the chamber. This gas is chemically non-reactive and will be used to create the plasma.

Step 3: Generating a Plasma

A high voltage is applied within the chamber, creating a strong electric field. This field energizes the argon gas, stripping electrons from the argon atoms and creating a plasma—a glowing, ionized gas consisting of positive argon ions (Ar+) and free electrons.

Step 4: The Collision and Ejection

The material to be deposited, the target, is given a negative charge. This causes the positively charged argon ions from the plasma to accelerate violently towards it. These ions slam into the target with enough force to transfer their momentum, knocking individual atoms or molecules of the target material loose. This ejection process is the "sputtering" itself.

Step 5: Deposition onto the Substrate

The ejected target atoms travel through the vacuum chamber and land on the substrate (the object being coated), which is strategically placed nearby. As these atoms accumulate, they build up layer by layer, forming a thin, dense, and highly adherent film.

Why Sputtering Is a Critical Technology

Sputtering is chosen over other deposition methods when the quality, purity, and adhesion of the thin film are paramount. Its advantages make it indispensable in high-performance applications.

Unmatched Versatility

Virtually any material can be deposited via sputtering. This includes pure metals, complex alloys, and even insulating ceramic compounds like oxides and nitrides, which are difficult or impossible to deposit using other methods like thermal evaporation.

Superior Film Quality and Adhesion

Sputtered atoms arrive at the substrate with significantly more kinetic energy than evaporated atoms. This high energy promotes better surface mobility, resulting in denser, more uniform films with fewer defects. It also embeds the atoms slightly into the substrate surface, creating exceptionally strong adhesion.

Precise Control Over Thickness

The process is extremely stable and repeatable, allowing for precise control over the film's thickness and composition. Engineers can create films with thicknesses controlled down to a single angstrom (one ten-billionth of a meter).

Understanding the Trade-offs

Despite its powerful advantages, sputtering is not the ideal solution for every situation. It's essential to understand its limitations.

Slower Deposition Rates

Generally, sputtering is a slower process compared to methods like thermal evaporation. This makes it less economical for applications requiring very thick coatings (many microns).

System Complexity and Cost

Sputtering systems require high-vacuum pumps, sophisticated power supplies, and process controls. This makes the equipment more complex and expensive to purchase and maintain than simpler deposition systems.

Line-of-Sight Limitations

Like a spray paint can, sputtering is a line-of-sight process. The sputtered material travels in a straight line from the target to the substrate, making it difficult to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces.

Potential for Substrate Heating

The energy transfer from the plasma and condensing atoms can significantly heat the substrate. While sometimes beneficial, this can damage heat-sensitive substrates like plastics or certain electronic components.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the specific requirements of your final product.

- If your primary focus is ultimate film purity, density, and adhesion for a complex material: Sputtering is often the superior technical choice.

- If your primary focus is high-speed, low-cost deposition of a simple metal: A process like thermal evaporation might be more efficient.

- If your primary focus is coating complex 3D shapes uniformly: You may need to explore non-line-of-sight methods like atomic layer deposition (ALD) or chemical vapor deposition (CVD).

Ultimately, understanding the principles of sputtering empowers you to select the precise manufacturing process for creating high-performance, durable surfaces.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Physical Vapor Deposition (PVD) |

| Core Mechanism | Momentum transfer from ion bombardment (e.g., Argon) to a target material |

| Primary Advantage | Superior film adhesion, density, and purity for complex materials |

| Common Applications | Semiconductor manufacturing, optical coatings, medical devices |

| Main Limitation | Line-of-sight process; slower for thick coatings |

Need a precise, high-quality coating for your project? The sputtering process is ideal for applications demanding exceptional film purity, adhesion, and uniformity. KINTEK specializes in advanced lab equipment and consumables for thin film deposition, serving R&D and production labs. Let our experts help you select the right sputtering solution to enhance your product's performance and durability. Contact us today to discuss your specific coating requirements!

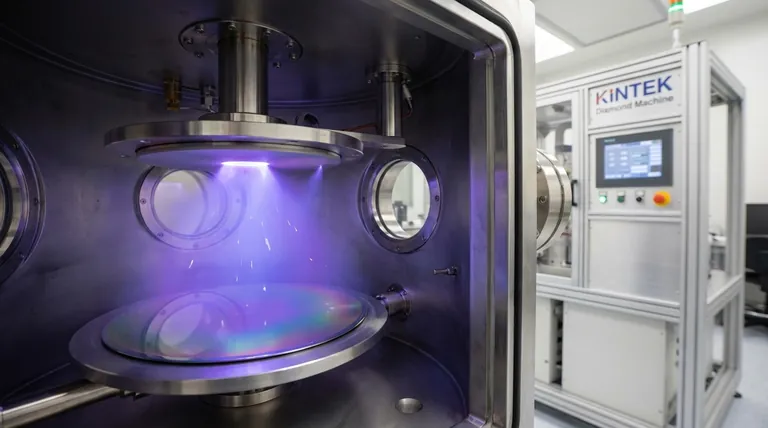

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What are CVD diamonds made of? Discover the Science Behind Lab-Grown Gems

- What is a potential application for the nanotubes? Boost Performance in Batteries, Composites & Electronics

- What is thickness uniformity of sputtering? The Key to Consistent Thin Film Quality

- What are the advantages of sputtering over evaporation? Achieve Superior Film Quality and Performance

- What is adhesion in thin film? The Key to Preventing Coating Failure

- What are the target materials for sputtering? From Metals to Ceramics for Precise Thin Films

- What is the difference between graphene and carbon? It's All About Atomic Structure

- Are carbon nanotubes hard to make? Mastering the Challenge of Scalable, High-Quality Production