The primary advantage of an e-beam evaporator is its ability to deposit high-purity films of high-melting-point materials with exceptional control over the deposition rate. Unlike a filament evaporator, which heats both the source material and a container "boat," an e-beam directly heats only the source material, enabling much higher temperatures and preventing contamination from the boat itself.

The choice between e-beam and thermal evaporation is a classic engineering trade-off. E-beam offers superior performance, material versatility, and purity for advanced applications, while thermal evaporation provides a simpler, more cost-effective solution for a range of common metals.

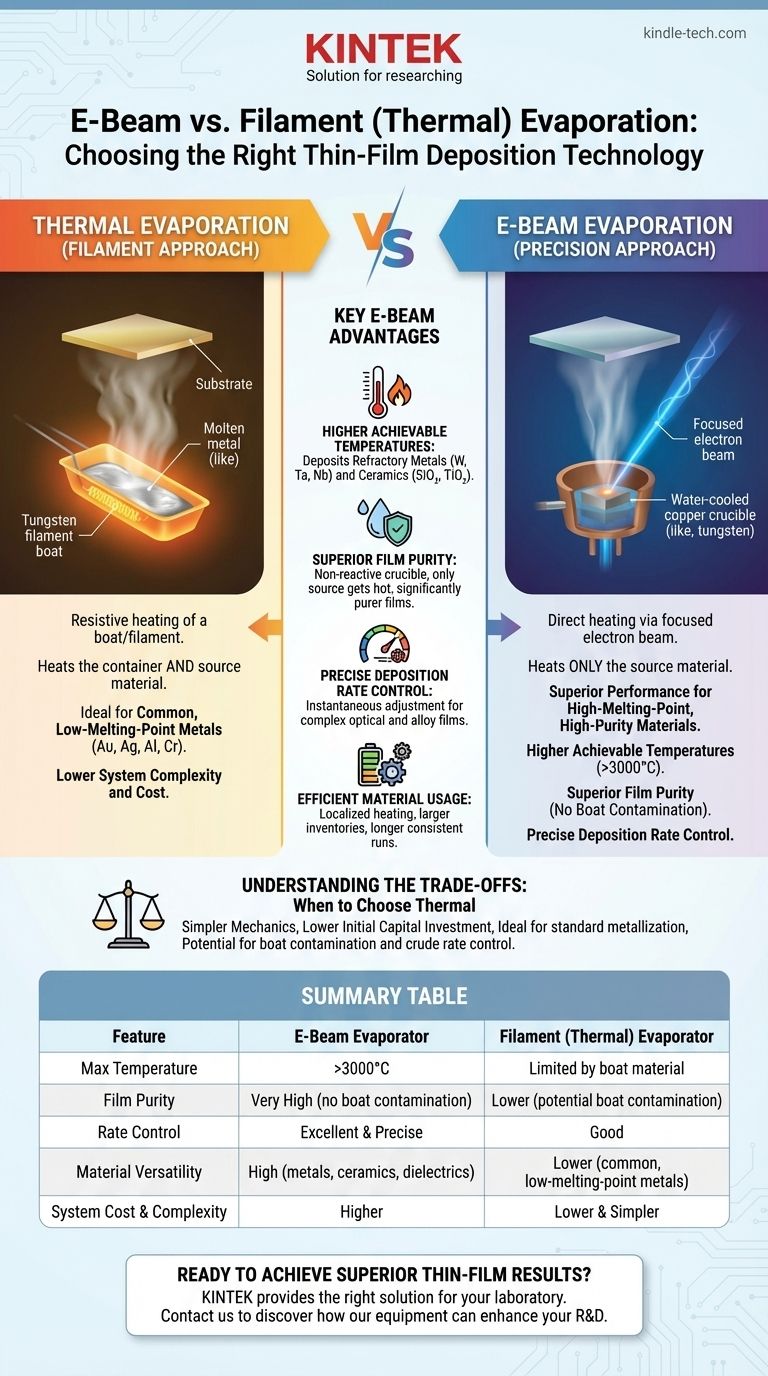

How Each Technology Works

To understand the advantages, we must first look at the fundamental difference in how each system generates vapor from a source material.

Thermal Evaporation (The Filament Approach)

Thermal evaporation is a process of resistive heating, much like an incandescent light bulb.

A high electrical current is passed through a resistive "boat" or filament, typically made of tungsten, molybdenum, or tantalum. The material to be deposited is placed in this boat, which heats up to the point where the material melts and then evaporates.

This vapor travels in a straight line within the vacuum chamber, coating everything in its path, including your substrate.

E-Beam Evaporation (The Precision Approach)

Electron beam (e-beam) evaporation is a more complex and targeted process.

A high-voltage power supply generates a powerful beam of electrons. This beam is then electromagnetically focused and steered onto the surface of the source material, which sits in a water-cooled copper hearth or crucible.

The intense, focused energy of the electrons is transferred directly to the material, causing a small spot on its surface to sublimate or evaporate. The water cooling prevents the crucible itself from melting or contaminating the process.

Key Advantages of E-Beam Evaporation

The fundamental difference in heating mechanisms gives e-beam evaporation several critical advantages for demanding applications.

Higher Achievable Temperatures

The direct energy transfer from the electron beam allows the source material to reach temperatures far exceeding 3000°C.

This makes it possible to deposit refractory metals like tungsten, tantalum, and niobium, as well as dielectrics and ceramics like silicon dioxide (SiO₂) and titanium dioxide (TiO₂), which are impossible to evaporate with standard thermal techniques.

Superior Film Purity

In thermal evaporation, the hot filament can react with or outgas, contaminating the vapor stream and reducing film purity.

Because the e-beam's water-cooled copper crucible remains cool, it is non-reactive. The only material that gets hot is the source material itself, leading to significantly purer deposited films. This is critical for optical, semiconductor, and medical applications.

Precise Deposition Rate Control

The power of the electron beam can be adjusted almost instantaneously, allowing for extremely fine and stable control over the evaporation rate.

This precision, often coupled with a quartz crystal microbalance (QCM) for feedback, is essential for creating complex optical interference coatings, graded-index layers, or well-defined alloy films where stoichiometry is critical.

Efficient Material Usage

The e-beam heats a small, localized spot on a larger source "puck." This is more energy-efficient than heating an entire boat and its contents. It also allows for much larger source inventories, enabling longer, more consistent deposition runs without breaking vacuum.

Understanding the Trade-offs: When to Choose Thermal

Despite the clear performance benefits of e-beam, it is not always the best choice. Simplicity and cost are major factors.

Lower System Complexity and Cost

Thermal evaporators are mechanically simpler. They do not require high-voltage power supplies, powerful electromagnets for beam steering, or the associated complex controllers.

This results in a significantly lower initial capital investment and often leads to simpler operation and maintenance.

Ideal for Common, Low-Melting-Point Metals

For standard metallization tasks using materials like gold (Au), silver (Ag), aluminum (Al), or chromium (Cr), thermal evaporation is highly effective, reliable, and far more economical.

If the absolute highest purity is not your primary concern, the simplicity of a thermal system is often the more practical choice for these common materials.

Limitations of Thermal Evaporation

The primary limitations of thermal evaporation are the potential for boat contamination, the inability to deposit high-temperature materials, and the comparatively crude control over the deposition rate.

Making the Right Choice for Your Goal

Your application's requirements for material type, film purity, and structural complexity will dictate the correct technology choice.

- If your primary focus is high-performance optical coatings or depositing refractory materials (W, Ta, SiO₂): E-beam evaporation is the necessary and superior choice for its purity, control, and temperature range.

- If your primary focus is simple metallization with common metals (Au, Al, Cr) for contacts or mirrors: Thermal evaporation is often the most practical and cost-effective solution.

- If your primary focus is process control for complex alloys or multilayer device structures: E-beam provides the fine, real-time rate control essential for achieving repeatable, high-quality results.

Selecting the right deposition method is the first and most critical step toward achieving your desired thin-film properties and performance.

Summary Table:

| Feature | E-Beam Evaporator | Filament (Thermal) Evaporator |

|---|---|---|

| Max Temperature | >3000°C | Limited by boat material |

| Film Purity | Very High (no boat contamination) | Lower (potential boat contamination) |

| Rate Control | Excellent & Precise | Good |

| Material Versatility | High (metals, ceramics, dielectrics) | Lower (common, low-melting-point metals) |

| System Cost & Complexity | Higher | Lower & Simpler |

Ready to Achieve Superior Thin-Film Results?

Whether your application demands the high purity and precision of an e-beam evaporator or the cost-effective simplicity of a thermal evaporator, KINTEK has the right solution for your laboratory. Our experts can help you select the perfect equipment to meet your specific material and performance goals.

Contact KINTEL today to discuss your thin-film deposition needs and discover how our lab equipment can enhance your research and development.

Visual Guide

Related Products

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- What are the advantages of RF magnetron sputtering? Achieve Superior Thin Film Deposition for Insulating Materials

- How hot can a metal surface get in the sun? The Surprising Science Behind Extreme Heat

- What is the temperature of the reflow process? Mastering the 240-250°C Peak for Perfect Solder Joints

- What can you make with an injection moulding machine? Mass-Produce High-Quality Plastic Parts Efficiently

- What are the disadvantages of plate and frame filter press? High Labor Costs and Inefficient Batch Processing

- Is biofuel a renewable energy source? Powering a Sustainable Future with Biomass

- What are the three types of tempering? Choose the Right Process for Hardness vs. Toughness

- What are the changes in mechanical properties due to slow cooling? Enhance Material Workability and Toughness