In short, the primary advantage of firing dental porcelain in a vacuum is to eliminate porosity. This process removes trapped air from between the porcelain powder particles, resulting in a final restoration that is significantly denser, stronger, and more aesthetically pleasing.

Firing porcelain without a vacuum traps countless microscopic air bubbles within the material. The core purpose of a vacuum is to remove this air before the porcelain particles fuse together, fundamentally improving the final physical and optical properties of the restoration.

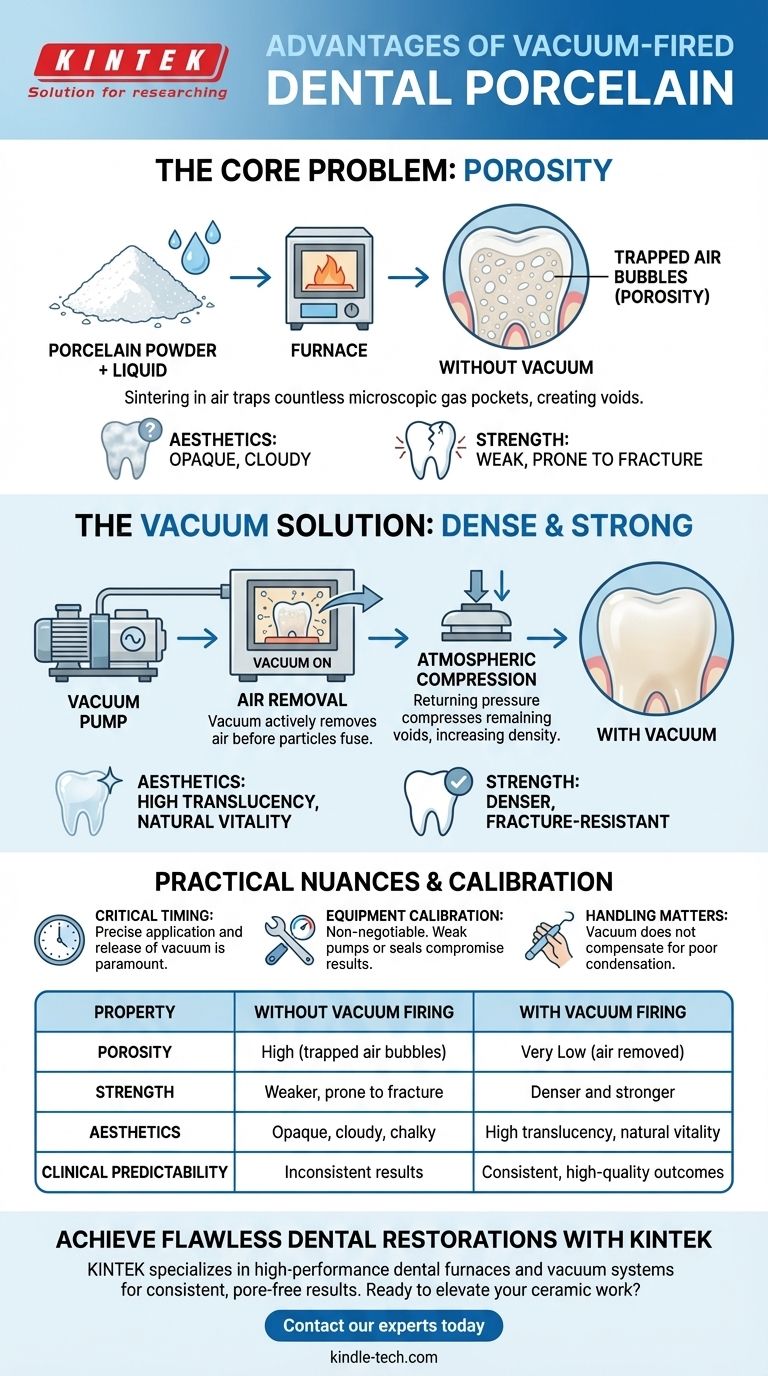

The Core Problem: Porosity in Air-Fired Ceramics

To understand the benefit of a vacuum, we must first examine the inherent flaw of firing ceramics in a normal atmosphere.

What is Porosity?

Dental porcelain begins as a fine powder mixed with a liquid to form a paste. This paste is built up and then heated in a furnace.

As the temperature rises, the individual particles soften and fuse together in a process called sintering.

If this process occurs in the presence of air, tiny pockets of atmospheric gas become trapped between the fusing particles, creating voids or bubbles within the final ceramic structure. This is known as porosity.

The Impact on Aesthetics

Porosity is the enemy of life-like aesthetics. These internal voids scatter light as it passes through the porcelain.

This light scattering makes the restoration appear opaque, cloudy, and chalky. It lacks the natural translucency and depth of a real tooth, which allows some light to pass through it.

The Impact on Strength

Each void inside the ceramic acts as a stress concentrator. It is a weak point where internal forces build up under pressure, such as from chewing.

When subjected to these forces, a crack is much more likely to initiate at one of these voids. A restoration with high porosity is therefore significantly weaker and more prone to fracture over time.

How Vacuum Firing Creates Superior Porcelain

A vacuum furnace systematically removes the air that would otherwise become trapped, directly solving the porosity problem.

Step 1: Removing Air Before Sintering

As the furnace temperature increases toward the sintering point, a vacuum pump actively removes the air from the firing chamber.

This evacuation pulls the air out from between all the individual porcelain particles. By the time the particles begin to soften and fuse, there is no air left to become trapped.

Step 2: Atmospheric Compression

Towards the end of the firing cycle, the vacuum is released, and atmospheric pressure is allowed back into the chamber.

This returning pressure physically pushes on the now-soft, semi-molten porcelain. This action helps to compress and shrink any remaining microscopic voids, further increasing the material's density.

The Result: A Denser, More Vital Restoration

By preventing the formation of voids, vacuum firing produces a ceramic that is fundamentally superior. It is denser, which directly leads to improved translucency for better aesthetics and greater internal strength for long-term durability.

Understanding the Practical Nuances

While the principle is straightforward, achieving perfect results requires precision. The vacuum itself is not a magic bullet.

The Critical Firing Schedule

The success of the process depends on the timing. The vacuum must be applied and held during the correct temperature range and then released at the precise moment to allow for optimal compression. Following the porcelain manufacturer's recommended firing schedule is paramount.

Equipment Calibration is Non-Negotiable

A weak vacuum pump or a poor seal on the furnace door will fail to remove enough air, compromising the final result. Regular maintenance and calibration of the furnace and vacuum pump are essential for consistent, high-quality outcomes.

It Cannot Fix Poor Handling

Vacuum firing will not compensate for improper condensation of the porcelain paste or contamination of the material. The foundational dental lab techniques of building a dense, clean restoration before it enters the furnace remain as critical as ever.

Making the Right Choice for Your Goal

Using a vacuum is the modern standard for a reason. It directly enables the key properties required for successful ceramic restorations.

- If your primary focus is aesthetics: Vacuum firing is essential for achieving the natural translucency and vitality that mimics a real tooth.

- If your primary focus is longevity and strength: Eliminating porosity is the single most important step to create a dense, fracture-resistant restoration that can withstand oral forces.

- If your primary focus is clinical predictability: A properly calibrated vacuum firing process provides consistent, repeatable results, reducing the chance of opaque or weak restorations that require remakes.

Mastering the principles of vacuum firing is fundamental to producing strong, beautiful, and durable ceramic dental work.

Summary Table:

| Property | Without Vacuum Firing | With Vacuum Firing |

|---|---|---|

| Porosity | High (trapped air bubbles) | Very Low (air removed) |

| Strength | Weaker, prone to fracture | Denser and stronger |

| Aesthetics | Opaque, cloudy, chalky | High translucency, natural vitality |

| Clinical Predictability | Inconsistent results | Consistent, high-quality outcomes |

Achieve Flawless Dental Restorations with KINTEK

Producing strong, beautiful, and durable ceramic dental work requires precision equipment and reliable processes. KINTEK specializes in high-performance dental furnaces and vacuum systems designed to deliver the consistent, pore-free results your lab demands.

Our expertise in lab equipment ensures you have the tools needed to master vacuum firing techniques, eliminate porosity, and enhance the strength and aesthetics of every restoration.

Ready to elevate your ceramic work? Contact our experts today to find the perfect furnace solution for your laboratory's needs.

Visual Guide

Related Products

- Vacuum Dental Porcelain Sintering Furnace

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing

- What is the strongest dental ceramic? Zirconia Leads in Strength, But Is It Right for Your Case?

- What is the sintering temperature of dental zirconia? Achieve Maximum Strength & Aesthetics

- In what contexts is a slow cooling protocol important for dental restorations? Ensure Durability with Precise Thermal Care

- What is the use of burnout oven? The Critical Step for Flawless Casting Results

- What properties of dental zirconia parts are affected by the sintering temperature? Master Thermal Precision

- What type of zirconia has better esthetics? Choose High-Translucency 4Y/5Y Zirconia for Superior Beauty

- How hot does a dental sintering furnace get? Unlock the Key to Perfect Restorations