For pure operational efficiency, the primary advantages of an induction furnace over an electric arc furnace (EAF) are its superior speed, higher thermal efficiency, and cleaner working environment. This is because heat is generated directly within the metal charge, a fundamentally different and more direct process than the external arc used in an EAF.

While an induction furnace offers clear benefits in speed and energy efficiency, the choice is not simple. The decision ultimately hinges on a critical trade-off between the induction furnace's precise, clean operation and the electric arc furnace's superior metallurgical refining capabilities and raw material flexibility.

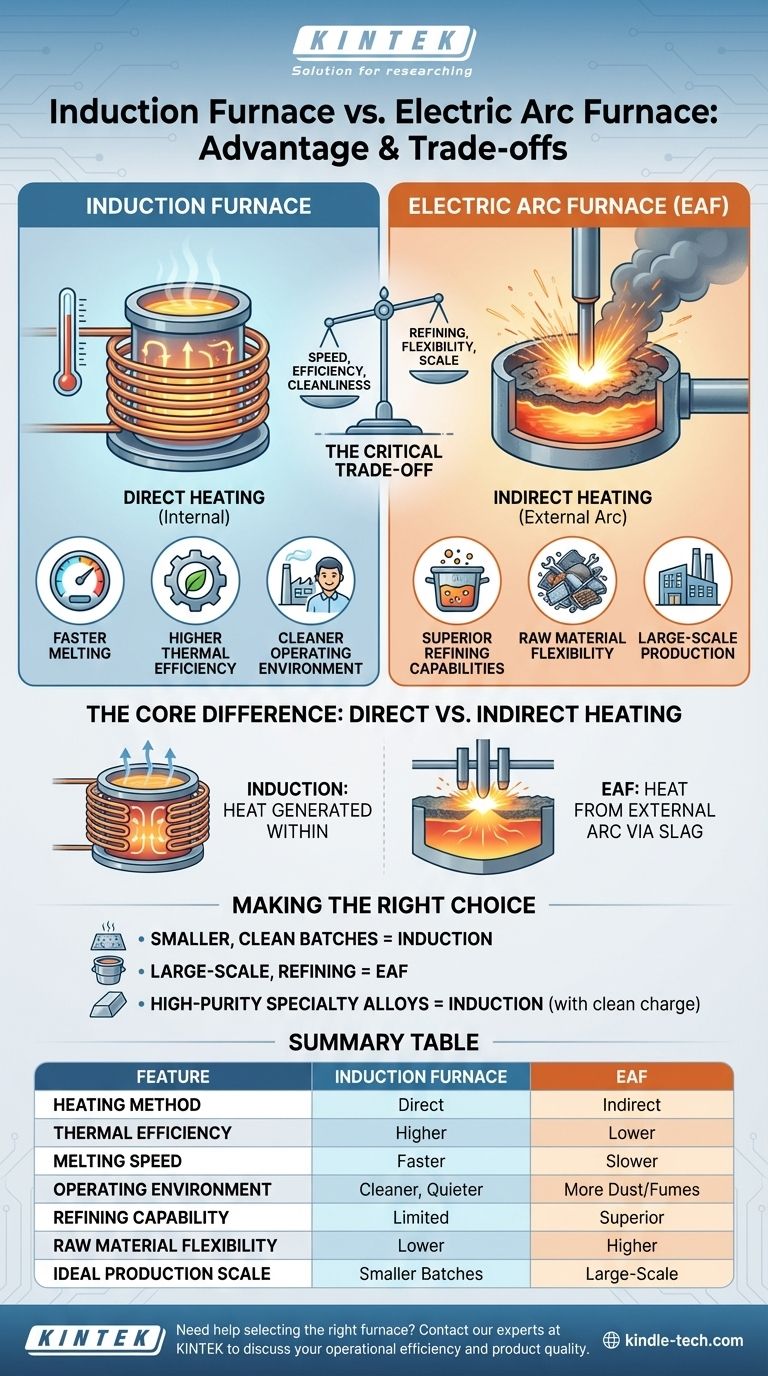

The Core Difference: Direct vs. Indirect Heating

The advantages and disadvantages of each furnace stem directly from how they introduce energy into the steel.

How Induction Furnaces Work

An induction furnace operates like a powerful, specialized microwave for metals. It uses an electric coil to create a strong alternating magnetic field.

This field induces electrical currents directly within the metallic charge material. The metal's natural resistance to these currents generates intense, rapid heat from the inside out.

How Electric Arc Furnaces Work

An EAF functions by passing a massive electrical current through graphite electrodes. This creates an extremely hot electric arc between the electrodes and the metal charge.

The heat from this arc is transferred to the metal, primarily through a layer of molten slag. This is an indirect heating method, as the heat source is external to the metal itself.

The Impact on Efficiency and Speed

This fundamental difference is the source of the induction furnace's main advantage. Direct heating is inherently more efficient.

Because heat is generated within the steel, less energy is lost to the furnace walls, cover, and surrounding environment. This results in faster melting times and higher overall thermal efficiency.

In contrast, the EAF's indirect heating process involves significant heat loss, making it less thermally efficient.

Key Operational Advantages of Induction Furnaces

Beyond the core heating method, induction technology provides several distinct operational benefits.

Superior Thermal Efficiency

As mentioned, generating heat directly inside the charge material minimizes wasted energy. This often translates to lower electricity consumption per ton of molten metal produced, a significant cost factor.

Cleaner Operating Environment

The absence of an electric arc means an induction furnace operates with significantly less noise, dust, and gaseous emissions. This creates a much-improved working environment for personnel and reduces the need for extensive fume and dust collection systems.

Precise Temperature Control

The electromagnetic nature of the heating process allows for very fine and rapid control over the temperature of the molten bath. The stirring action created by the magnetic fields also ensures a homogenous temperature and chemistry throughout the melt.

Understanding the Trade-offs: Why EAFs Remain Vital

Despite these advantages, the induction furnace is not a universal replacement for the EAF. The EAF possesses critical capabilities that make it indispensable for many applications.

Metallurgical Refining Capabilities

This is the most significant advantage of the EAF. The slag layer in an EAF is not just a heat transfer medium; it is an active metallurgical tool. It is used to remove impurities like sulfur and phosphorus from the steel.

Induction furnaces have a less active (or colder) slag, which limits their ability to perform this kind of extensive refining. They are best suited for melting clean scrap or pre-refined materials where the final chemistry is already close to the target.

Raw Material Flexibility

The sheer power and intense, localized heat of the electric arc allow an EAF to process a much wider range of raw materials. It can effectively melt large, dense, and lower-quality scrap.

Induction furnaces generally require a charge of cleaner, smaller, and more uniform scrap to operate efficiently.

Scale of Production

Electric arc furnaces can be built to massive scales, with capacities exceeding 300 tons. They are the workhorses of modern "mini-mills" for large-scale steel production.

Induction furnaces are typically smaller, making them ideal for foundries, specialty steel producers, and operations requiring smaller, discrete batches of metal.

Making the Right Choice for Your Goal

Selecting the correct furnace technology requires aligning the equipment's strengths with your specific production objectives.

- If your primary focus is operational efficiency for smaller, clean batches: The induction furnace is the superior choice for its speed, energy savings, and cleaner environment.

- If your primary focus is large-scale production with robust refining: The electric arc furnace is the industry standard due to its ability to handle diverse scrap and actively refine steel chemistry.

- If your primary focus is producing high-quality specialty alloys: A modern induction furnace is ideal, provided you begin with a high-purity charge material that does not require extensive refining.

Ultimately, understanding these fundamental differences in heating and refining allows you to select the furnace technology that aligns precisely with your material requirements, production scale, and operational priorities.

Summary Table:

| Feature | Induction Furnace | Electric Arc Furnace (EAF) |

|---|---|---|

| Heating Method | Direct (internal to metal) | Indirect (via electric arc) |

| Thermal Efficiency | Higher | Lower |

| Melting Speed | Faster | Slower |

| Operating Environment | Cleaner, quieter | More dust/fumes/noise |

| Refining Capability | Limited (needs clean charge) | Superior (removes impurities) |

| Raw Material Flexibility | Lower (needs uniform scrap) | Higher (handles diverse scrap) |

| Ideal Production Scale | Smaller batches, specialty alloys | Large-scale production |

Need help selecting the right furnace for your lab or production needs?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Whether you're melting specialty alloys or require efficient, small-batch processing, our expertise can guide you to the optimal solution.

Contact our experts today to discuss how the right furnace technology can enhance your operational efficiency and product quality.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is VIM in metallurgy? A Guide to Vacuum Induction Melting for High-Performance Alloys

- What is vacuum arc melting technique? Discover the Precision of Vacuum Induction Melting

- What is the principle of vacuum induction melting? Achieve Ultra-High Purity Metals

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Controlled Metal Melting

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity