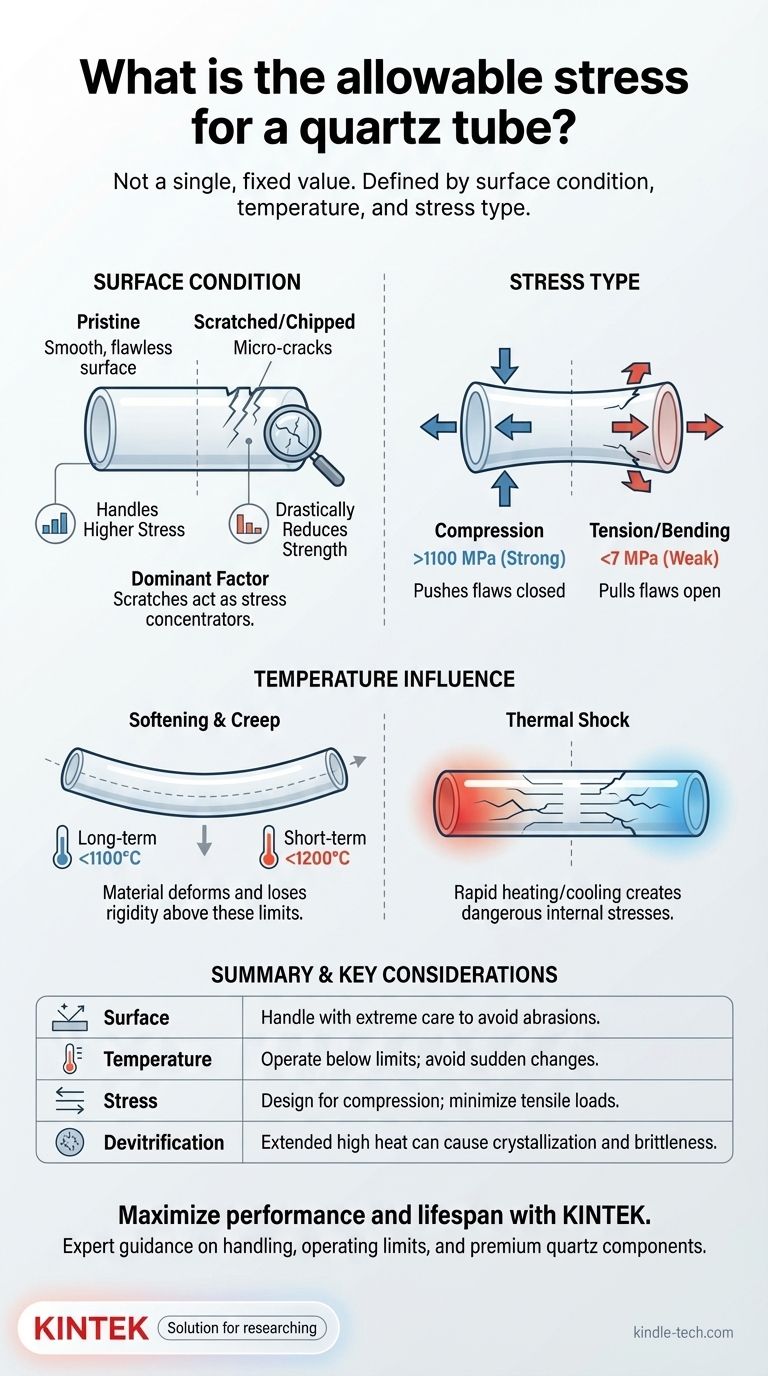

The allowable stress for a quartz tube is not a single, fixed value. Unlike metals with predictable yield points, fused quartz is a brittle ceramic whose true strength is dictated by a combination of factors, primarily surface condition and temperature. Any published stress value is highly conditional, as its practical limits are more often defined by its susceptibility to thermal shock and deformation at high temperatures than a simple mechanical load capacity.

The practical strength of a quartz tube is determined less by a theoretical stress value and more by meticulously controlling its operating conditions. Preventing failure means managing temperature, protecting the tube surface from any damage, and minimizing both thermal and mechanical shock.

Why a Single "Allowable Stress" is Misleading

To use quartz reliably, we must shift our thinking from a single strength number to understanding the factors that cause it to fail. Quartz does not bend or deform before breaking; it fractures suddenly.

The Nature of Brittle Fracture

Fused quartz, like all ceramics and glasses, fails due to brittle fracture. This process is initiated at microscopic flaws, most often on the surface of the material.

These tiny, unavoidable imperfections act as stress concentrators. When a load is applied, the stress at the tip of one of these flaws can be many times higher than the overall stress on the part, leading to catastrophic failure.

The Dominant Role of Surface Condition

The size and sharpness of the largest flaw determine the strength of the entire component. This is why a pristine, fire-polished quartz tube is significantly stronger than one with even a minor scratch or chip.

This is the principle behind the warnings to handle quartz gently. A seemingly insignificant abrasion can dramatically reduce the tube's ability to withstand stress.

Compressive vs. Tensile Strength

Quartz is exceptionally strong under compression, where external forces are pushing flaws closed. Typical compressive strength can be over 1100 MPa (160,000 psi).

However, it is dramatically weaker under tension or bending (flexural stress), as these forces pull flaws open. A typical safe design value for tensile strength is often conservatively estimated at less than 7 MPa (1,000 psi) to account for unknown surface conditions.

The Critical Influence of Temperature

The references correctly highlight that temperature is a primary operational limit. This impacts the material's integrity in two distinct ways.

Softening and Creep Deformation

As quartz approaches its softening point, it begins to lose its rigidity. The stated long-term use temperature of 1100°C and short-term limit of 1200°C relate to this phenomenon.

Above these temperatures, the material will begin to deform or sag under its own weight, a process known as creep. This is a deformation failure, not a fracture.

Thermal Shock: The Silent Killer

Because quartz has a very low coefficient of thermal expansion, it is highly resistant to thermal shock compared to other ceramics. However, it is not immune.

Rapid heating or cooling creates internal temperature gradients, which in turn create internal stresses. If these stresses are high enough to propagate a surface flaw, the tube will fracture. This is a common cause of failure in laboratory and industrial settings.

Understanding the Practical Limitations

Accepting the inherent properties of quartz is crucial for successful design and operation.

Fragility is Non-Negotiable

The references emphasize careful handling to avoid "violent vibrations and collisions" for a reason. Quartz has very low fracture toughness, meaning it cannot absorb much energy before fracturing. Always assume it is fragile.

Devitrification Reduces Strength

When held at high temperatures (typically above 1100°C) for extended periods, the amorphous fused quartz can begin to crystallize into a form called cristobalite. This process, called devitrification, makes the tube opaque and significantly more brittle, especially during subsequent heating and cooling cycles.

Alternatives for Extreme Conditions

As noted, when operational temperatures must consistently exceed 1100-1200°C, a different material is required. Corundum (high-purity alumina) is a common alternative for higher-temperature applications, though it has different thermal shock and chemical resistance properties.

How to Ensure Reliability in Your Application

Instead of seeking a single stress number, focus on mitigating the most likely causes of failure for your specific use case.

- If your primary focus is high-temperature stability: Operate well below the 1100°C long-term limit, especially if the tube is under any load (even its own weight over a long span).

- If your primary focus is mechanical integrity (e.g., vacuum or low pressure): Prioritize protecting the tube surface from any scratches, chips, or abrasions, both inside and out.

- If your primary focus is longevity and repeated use: Implement controlled, gradual heating and cooling ramps to minimize the risk of thermal shock.

Ultimately, treating your quartz components with a deep understanding of their brittle nature is the key to their successful and long-term use.

Summary Table:

| Factor | Impact on Quartz Tube Strength | Key Consideration |

|---|---|---|

| Surface Condition | Dominant factor; scratches or chips drastically reduce strength. | Handle with extreme care to avoid abrasions. |

| Temperature | Defines operational limits; softening occurs above 1100°C. | Long-term use below 1100°C; short-term below 1200°C. |

| Stress Type | Strong in compression (>1100 MPa), weak in tension (<7 MPa). | Avoid bending or tensile loads in design. |

| Thermal Shock | Rapid temperature changes can cause sudden fracture. | Use controlled heating/cooling ramps. |

Maximize the performance and lifespan of your quartz components with KINTEK.

Designing a reliable high-temperature process requires more than just a material spec; it demands expert guidance on handling, operating limits, and application-specific best practices. KINTEK specializes in premium lab equipment and consumables, including quartz tubes, and our experts are here to help you select the right materials and implement practices that prevent failure.

We provide:

- High-purity, durable quartz tubes designed for critical applications.

- Technical support to optimize your heating processes and avoid common pitfalls like thermal shock.

- Alternative solutions, like corundum tubes, for extreme temperature needs.

Don't leave your process to chance. Contact our experts today for a consultation to ensure your lab's safety and efficiency.

Visual Guide

Related Products

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does a three-zone high-temperature split tube furnace ensure data accuracy in creep experiments? Achieve Thermal Precision

- How does a temperature-controlled tube furnace influence the performance of biochar adsorbents? Optimize Pore Structure

- Why is a controlled atmosphere tube furnace required for HPS catalysts? Ensure Optimal Metal Site Activation

- What are the advantages of using multi-stage split tube furnaces for heating methane pyrolysis reactors? Boost Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of SPAN? Optimize Your Li-S Battery Research Today