While sintering is a unique powder metallurgy process, its primary alternatives in manufacturing are casting, forging, and machining. These methods do not rely on consolidating powders but instead shape materials that are in a liquid, solid, or bulk state. The choice between them depends entirely on the desired material properties, component complexity, production volume, and cost constraints.

The core decision is not about finding a direct replacement for sintering, but about choosing the right manufacturing philosophy. You can either build a part from powder (sintering), form it from liquid (casting), deform it from a solid (forging), or carve it from a block (machining).

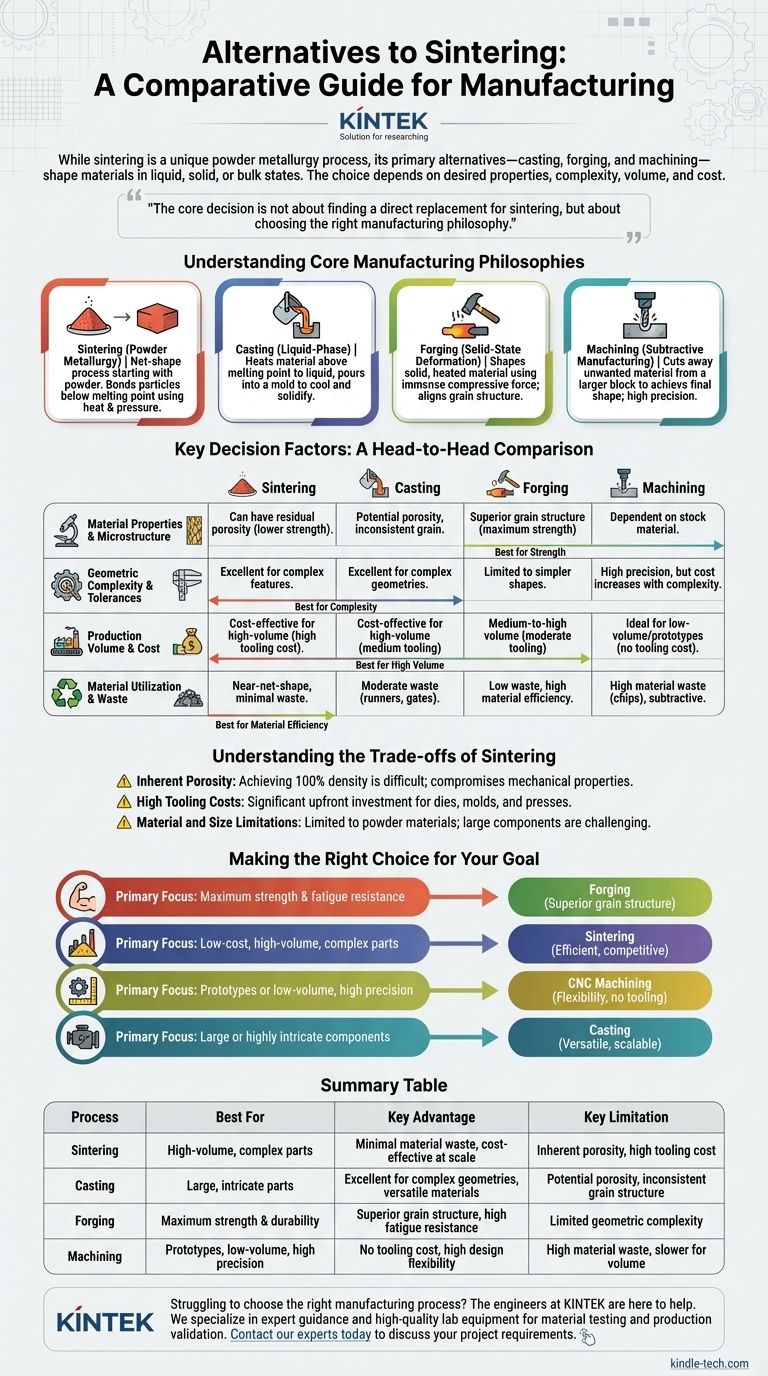

Understanding the Core Manufacturing Philosophies

To choose an alternative, you must first understand the fundamental difference in how each process works. Sintering is a "net-shape" process that starts with powder, while its main alternatives manipulate bulk material.

Powder Metallurgy (Sintering)

Sintering transforms a mass of powder into a solid, dense object using heat and pressure below the material's melting point. This process bonds the powder particles together, creating a strong final component. It excels at producing complex shapes with minimal material waste.

Liquid-Phase Processing (Casting)

Casting involves heating a material well above its melting point until it is fully liquid. This molten material is then poured into a mold, where it cools and solidifies into the final shape. It is a highly versatile process suitable for a wide range of sizes and complex geometries.

Solid-State Deformation (Forging)

Forging takes a solid piece of material, typically a heated billet, and shapes it using immense compressive force from a hammer or a press. This process does not melt the material but plastically deforms it, aligning the internal grain structure and often producing exceptionally strong and durable parts.

Subtractive Manufacturing (Machining)

Machining is the opposite of sintering. It starts with a larger block or bar of solid material (stock) and systematically cuts away unwanted material to achieve the final shape. Processes like milling, turning, and drilling fall under this category, offering high precision and design flexibility.

Key Decision Factors: A Head-to-Head Comparison

Choosing the right process requires a clear-eyed evaluation of your project's specific needs. Each method offers a distinct profile of strengths and weaknesses across key engineering and business criteria.

Material Properties & Microstructure

Forging typically produces the strongest components due to its ability to refine and align the material's grain structure, eliminating defects. Cast parts can have issues like porosity or inconsistent grain size. Sintered parts can suffer from residual porosity, which may act as a stress concentration point and limit ultimate strength unless secondary densification processes are used.

Geometric Complexity & Tolerances

Casting and sintering are champions of complexity, capable of producing intricate internal and external features in a single step. Machining can achieve extremely high precision and complex shapes, but the cost and time increase dramatically with complexity. Forging is generally limited to simpler geometries, as the material must be able to flow within the dies.

Production Volume & Cost

For high-volume production (thousands to millions of parts), sintering and casting are often the most cost-effective once the initial tooling costs are covered. Machining is ideal for prototypes and low-volume runs because it requires no custom tooling, but its per-part cost remains high. Forging fits in the middle, with moderate tooling costs suitable for medium-to-high volume production.

Material Utilization & Waste

Sintering is an exceptionally efficient "near-net-shape" process, converting nearly all the starting powder into the final part. This minimizes waste and cost. In stark contrast, machining is a subtractive process that can generate significant amounts of scrap material (chips), which must be recycled at an additional cost.

Understanding the Trade-offs of Sintering

To fairly compare sintering to its alternatives, it is critical to acknowledge its inherent limitations. These trade-offs are often the primary reason an engineer might choose another process.

Inherent Porosity

Achieving full 100% density in a sintered part is difficult and often requires secondary operations. This residual porosity can compromise mechanical properties like tensile strength and fatigue resistance compared to a forged or wrought equivalent.

High Tooling Costs

The dies, molds, and presses used in sintering represent a significant upfront capital investment. This makes the process economically unviable for prototypes, custom parts, or low-volume production runs.

Material and Size Limitations

The sintering process is limited to materials that can be readily formed into powder. Furthermore, producing very large components via sintering can be challenging and expensive due to the massive press sizes and tooling required.

Making the Right Choice for Your Goal

Your decision should be guided by your single most important requirement.

- If your primary focus is maximum strength and fatigue resistance: Forging is often the superior choice due to its ability to create a favorable grain structure.

- If your primary focus is low-cost, high-volume production of complex parts: Sintering is an extremely competitive and efficient manufacturing option.

- If your primary focus is creating prototypes or very low-volume runs with high precision: CNC machining provides the most flexibility with no initial tooling investment.

- If your primary focus is creating large or highly intricate components where cost is a major driver: Casting offers a versatile and scalable solution for a wide range of materials.

By understanding these fundamental trade-offs, you can confidently select the manufacturing process that best serves your engineering and business objectives.

Summary Table:

| Process | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Sintering | High-volume, complex parts | Minimal material waste, cost-effective at scale | Inherent porosity, high tooling cost |

| Casting | Large, intricate parts | Excellent for complex geometries, versatile materials | Potential porosity, inconsistent grain structure |

| Forging | Maximum strength & durability | Superior grain structure, high fatigue resistance | Limited geometric complexity |

| Machining | Prototypes, low-volume, high precision | No tooling cost, high design flexibility | High material waste, slower for volume |

Struggling to choose the right manufacturing process for your components? The engineers at KINTEK are here to help. We specialize in providing expert guidance and high-quality lab equipment to support your material testing and production validation. Whether you're sintering metal powders or evaluating alternative methods, our expertise ensures you achieve optimal results.

Contact our experts today to discuss your project requirements and discover how KINTEK's solutions can enhance your manufacturing efficiency and product performance.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- How big is the hot isostatic pressing market? Growth Drivers in Aerospace, Medical & 3D Printing

- What does HIP process do? Eliminate Porosity for Superior Material Performance

- What are the advantages and limitations of hot isostatic pressing? Achieve Ultimate Material Integrity

- What is the HIP material process? Achieve Near-Perfect Density and Reliability

- How does Hot Isostatic Pressing reduce porosity? Eliminate Internal Voids for Superior Material Density