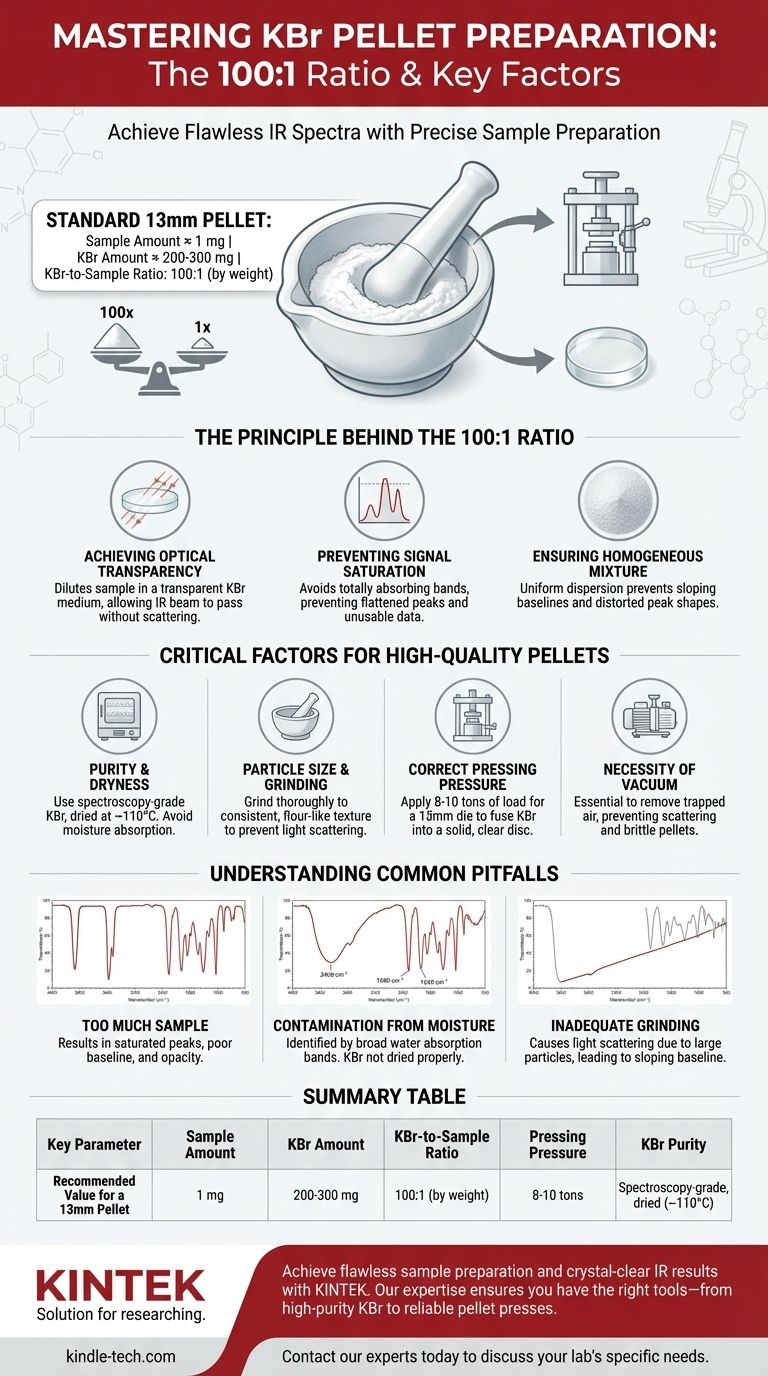

For a standard 13 mm KBr pellet, the recommended amount of sample is approximately 1 mg, which should be thoroughly mixed with 200 to 300 mg of dry, spectroscopy-grade potassium bromide (KBr). This adheres to the widely accepted 100:1 KBr-to-sample ratio by weight, a crucial guideline for producing a high-quality pellet that yields a clear and accurate infrared spectrum.

The ultimate goal of a KBr pellet is to uniformly disperse a minute amount of sample within an optically transparent matrix. The precise weight is less important than achieving the correct sample-to-KBr ratio and ensuring all components are perfectly dry, which prevents signal distortion and spectral artifacts.

The Principle Behind the 100:1 Ratio

The quality of your final infrared (IR) spectrum is entirely dependent on the quality of your KBr pellet. The 100:1 ratio is not arbitrary; it is based on fundamental principles of how light interacts with matter.

Achieving Optical Transparency

Potassium bromide is used because it is transparent to infrared radiation in the typical analysis range. Your solid sample is not. By diluting the sample significantly, you create a medium where the sample particles are isolated, allowing the IR beam to pass through the pellet without being completely blocked or scattered.

Preventing Signal Saturation

Using too much sample (a low KBr:sample ratio) is a common mistake. This causes the strongest absorption bands in your spectrum to become "totally absorbing." The detector receives no light at these frequencies, causing the peaks to appear flattened at the top, which makes the resulting data unusable for any quantitative analysis.

Ensuring a Homogeneous Mixture

A uniform dispersion of the sample within the KBr is critical. If the sample is not ground and blended thoroughly, you create pockets of high and low concentration. This inconsistency leads to a sloping baseline and distorted, unreliable peak shapes in the final spectrum.

Critical Factors for a High-Quality Pellet

Beyond just the sample weight, several other factors are crucial for producing a transparent, durable pellet that will yield a clean spectrum.

The Purity and Dryness of KBr

KBr is hygroscopic, meaning it readily absorbs moisture from the air. Water has strong IR absorption bands that will appear in your spectrum and obscure your sample's signals. Always use finely pulverized (200 mesh) KBr dried in an oven at ~110°C for several hours before use.

Particle Size and Grinding

The particle size of both the sample and the KBr must be smaller than the wavelength of the IR radiation being used. This prevents an issue known as light scattering (the Christiansen effect), which results in a significantly sloping baseline and reduced spectral clarity. Grind the sample and KBr together thoroughly in an agate mortar and pestle until the mixture has a consistent, flour-like texture.

Correct Pressing Conditions

Forming a transparent pellet requires immense pressure. For a standard 13 mm die, a load of 8 to 10 tons is typically applied. This pressure causes the KBr to cold-flow and fuse into a solid, glass-like disc. Insufficient pressure results in a cloudy or opaque pellet that will scatter light excessively.

The Necessity of a Vacuum

Applying a vacuum to the die set during the pressing process is essential. This removes trapped air from between the KBr particles. Without a vacuum, these air pockets cause scattering and can make the finished pellet brittle and prone to fracturing.

Understanding the Common Pitfalls

Troubleshooting KBr pellets is a common task in spectroscopy. Understanding the cause of a poor result is key to fixing it.

Pitfall: Too Much Sample

This is the most frequent error. The result is a spectrum with excessively intense, flattened peaks and a very poor, noisy baseline. The pellet itself may also have a noticeable color or opacity.

Pitfall: Contamination from Moisture

If you see a very broad absorption band around 3400 cm⁻¹ and a sharp peak near 1640 cm⁻¹, your pellet is contaminated with water. This confirms that the KBr was not dried properly or was exposed to humid air for too long.

Pitfall: Inadequate Grinding

If your spectrum has a baseline that slopes severely from left to right, it is a classic sign of light scattering. This means the particles in the pellet are too large and are deflecting the IR beam instead of allowing it to pass through.

Making the Right Choice for Your Goal

Your specific analytical goal should guide your sample preparation.

- If your primary focus is qualitative identification: Start with the 100:1 ratio, but a small deviation is acceptable as long as you can clearly identify all characteristic peaks without saturation.

- If your primary focus is quantitative analysis: Consistency is everything. You must precisely weigh both the sample and KBr for every pellet to ensure the ratio is identical across all standards and unknowns.

- If your spectrum is noisy with very weak peaks: You have likely used too little sample. Remake the pellet, carefully increasing the amount of sample material.

- If your spectrum has flattened peaks and a sloping baseline: You have used too much sample and/or have not ground it finely enough. Reduce the sample amount and ensure you grind the mixture thoroughly.

Mastering the KBr pellet technique is about methodically controlling the key variables—ratio, moisture, and particle size—to create a perfect window for viewing your sample's molecular structure.

Summary Table:

| Key Parameter | Recommended Value for a 13mm Pellet |

|---|---|

| Sample Amount | 1 mg |

| KBr Amount | 200-300 mg |

| KBr-to-Sample Ratio | 100:1 (by weight) |

| Pressing Pressure | 8-10 tons |

| KBr Purity | Spectroscopy-grade, dried (~110°C) |

Achieve flawless sample preparation and crystal-clear IR results with KINTEK.

Our expertise in laboratory equipment and consumables ensures you have the right tools—from high-purity KBr to reliable pellet presses—to master the KBr pellet technique. Whether you're focused on qualitative identification or precise quantitative analysis, we provide the quality and support you need for accurate, reproducible data.

Contact our experts today to discuss your lab's specific needs and discover how KINTEK can enhance your spectroscopy workflow.

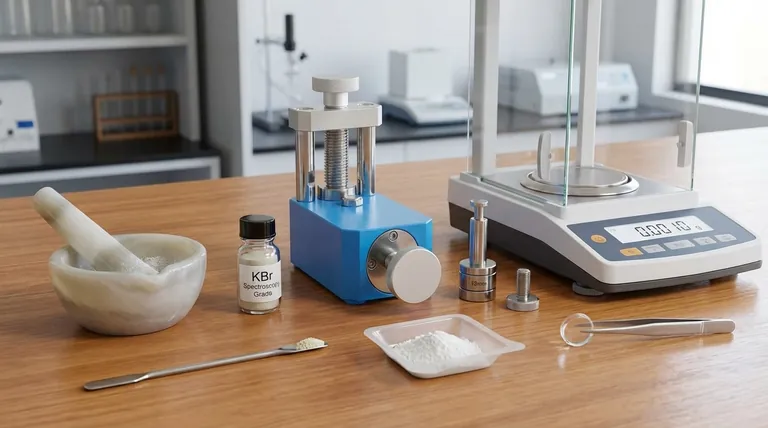

Visual Guide

Related Products

- kbr pellet press 2t

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- Why do we use KBr in IR spectroscopy? Achieve Clear, High-Quality Solid Sample Analysis

- What are the different types of sampling techniques used in IR spectroscopy? A Guide to KBr, Mull, and ATR Methods

- How do you prepare a KBr pellet for IR spectroscopy? Master the Key Steps for a Clear Spectrum

- Why only KBr is used in IR spectroscopy? The Truth About the Best Material for Your Sample

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis